Control method of wood sanding equipment and automatic wood sanding equipment

A control method and a sanding technology are applied in the control of wood sanding equipment and in the field of automatic wood sanding equipment, which can solve the problems of uneven sanding processing times, affecting the surface flatness of the inner groove, and heavy labor for operators. , to achieve good effect and reduce the amount of manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] see Figure 1 to Figure 14 , the control method of wood sanding equipment of the present invention, described control method comprises the following steps:

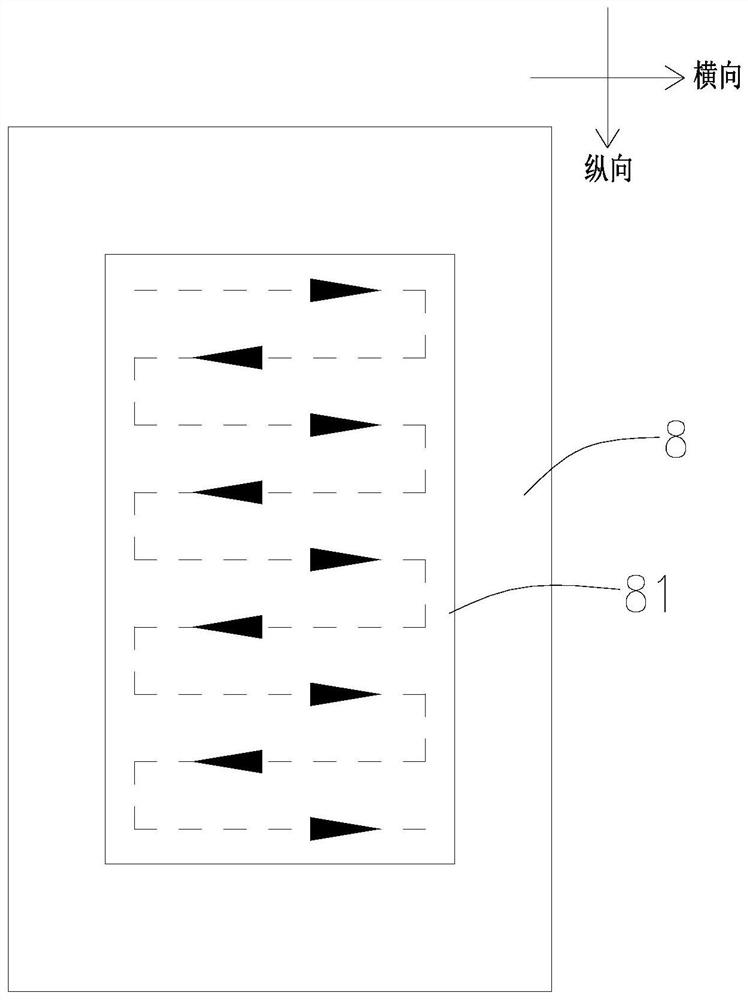

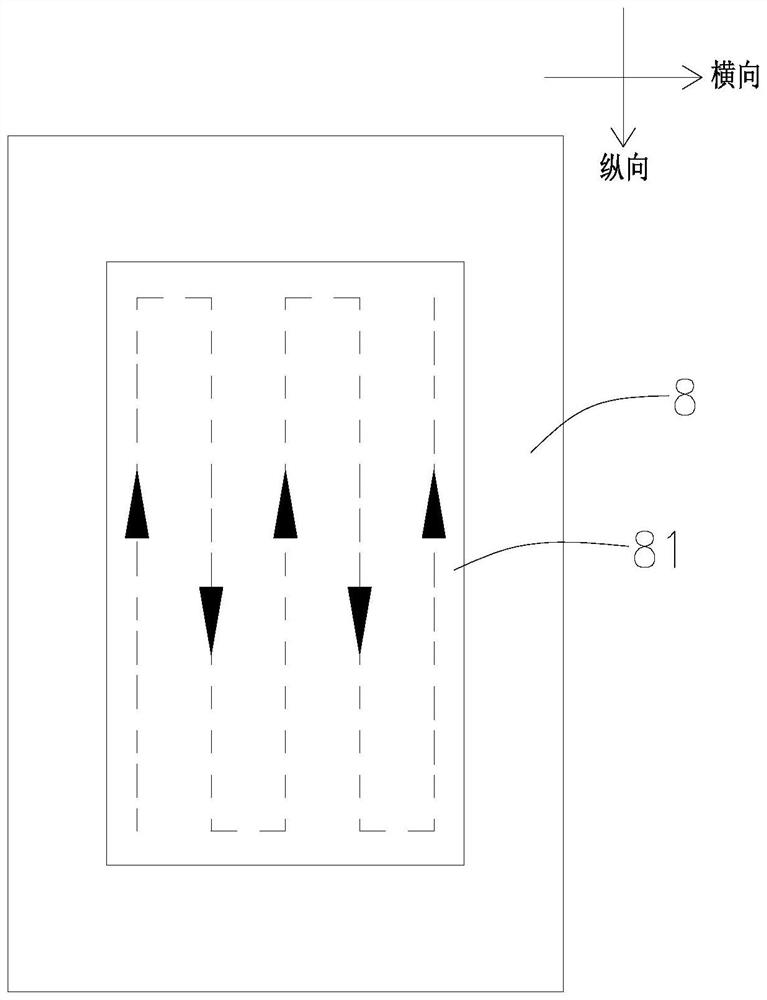

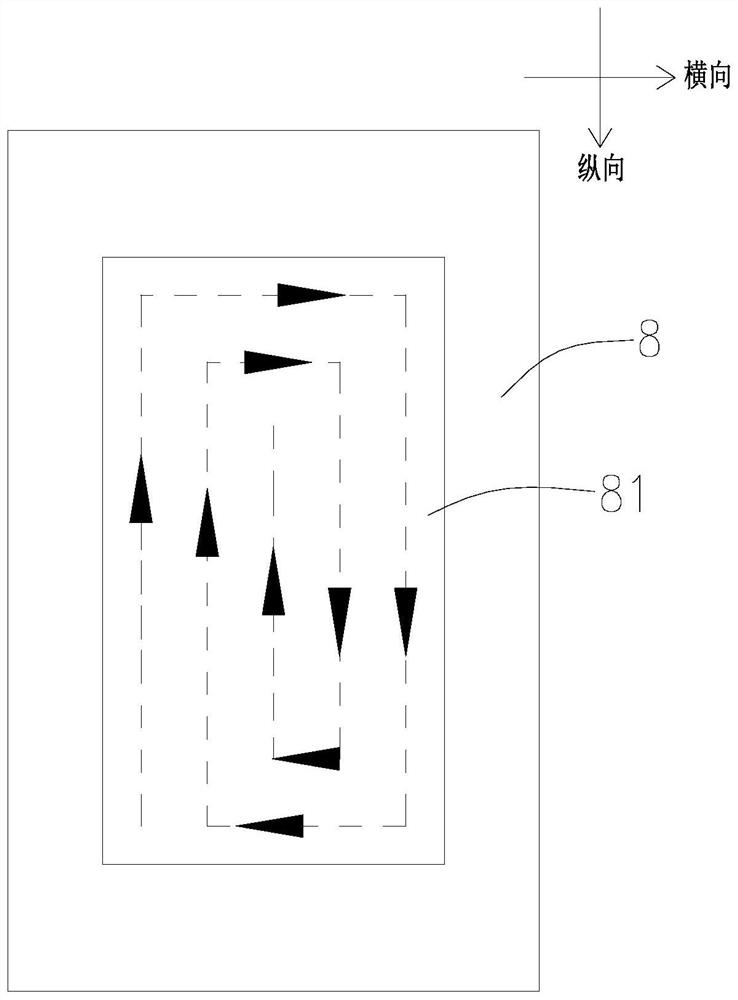

[0044] a. The scanning device scans the wood 8 to be processed entering the conveying mechanism 11 to obtain the outer dimensions of the wood 8 to be processed and the dimensions of the inner groove 81. The outer dimensions include the height and shape of the wood, and the dimensions of the inner groove 81 include the depth of the inner groove 81 and shape dimensions.

[0045] b. According to the external dimensions of the wood 8 to be processed and the size of the inner tank 81, the control module of the wood sanding equipment controls the slot sanding assembly to perform sanding on the inner tank 81 of the wood 8 to be processed, and controls the grinding wheel mechanism 24 to be processed The outer surface of the wood 8 is sanded.

[0046]Compared with the prior art, in the control method of the wood sanding e...

Embodiment 2

[0061] see Figure 8 to Figure 14 , the automatic wood sanding equipment of the present invention includes a conveying mechanism 11, a scanning device (not shown), a control module, a sanding mechanism 2 located above the conveying mechanism 11, and drives the sanding mechanism 2 longitudinally. The displacement longitudinal drive mechanism 3, the transverse drive mechanism 4 that drives the lateral displacement of the sand grinding mechanism 2, and the first vertical drive assembly 211 and the second vertical drive assembly 231, the scanning device is used for scanning into the conveying mechanism The wood 8 to be processed in 11 obtains the outer dimensions of the wood 8 to be processed and the size of the inner groove 81, so that the control module controls the sanding mechanism 2 to sand the surface of the wood 8 to be processed according to the acquired outer dimensions and the size of the inner groove 81 , the scanning device is an existing technology in the technical fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com