Sample storing apparatus of rubber sample picking machine

A sample collection and storage device technology, applied in the direction of sampling devices, measuring devices, instruments, etc., can solve the problems of sample bonding or pasting transfer accidents, and the absence of rubber sample storage devices, etc., to achieve minimization, labor saving, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

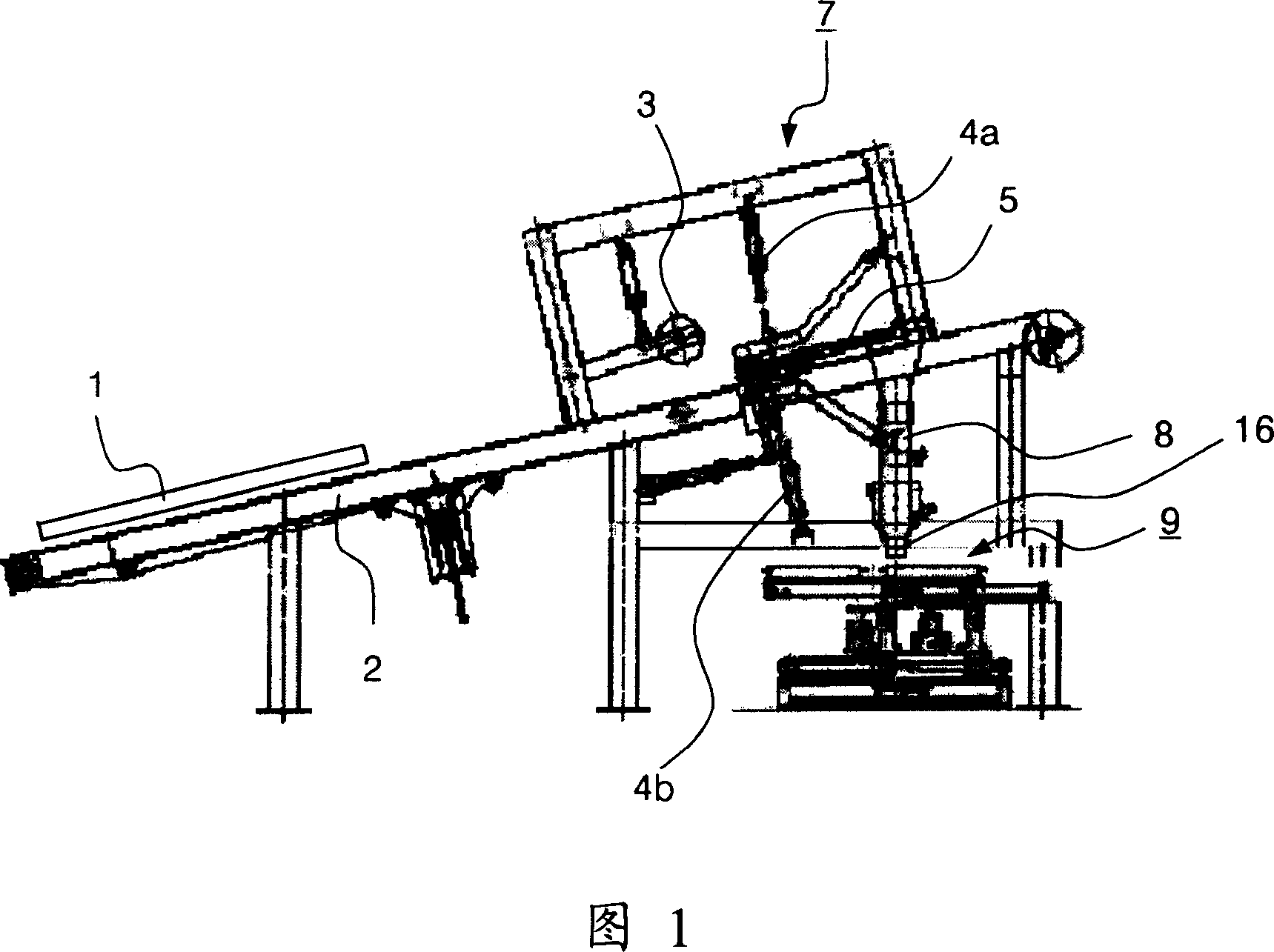

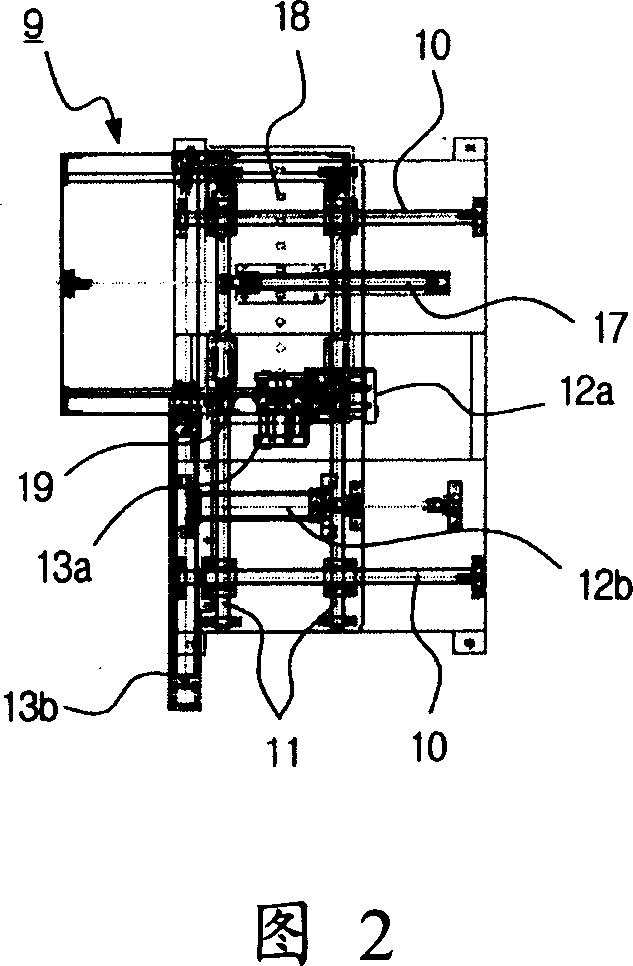

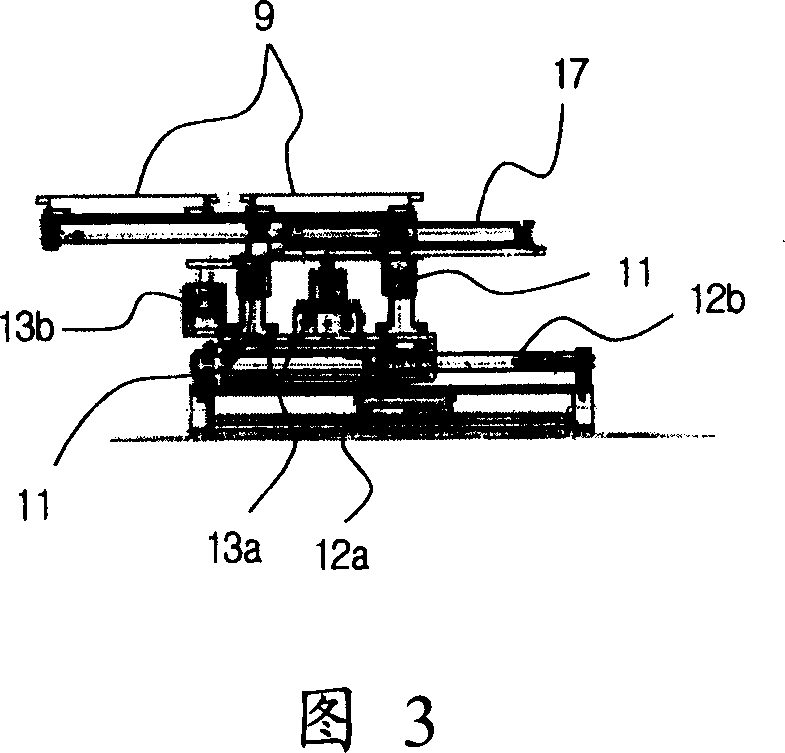

[0017] Fig. 1 is the overall structural diagram of the rubber sample collecting machine applicable to the present invention, and Fig. 2 to Fig. 4 are the top view of the sample storage device for storing the rubber samples collected by the rubber sample collecting machine as the main part of the present invention, Front view and side view. The present invention relates to a sample storage device of a rubber sample collection machine. The rubber sample collection machine includes: a conveyor 2 for conveying rubber sheets 1; The holding device 5 collects the rubber sample 6 from the transferred rubber sheet 1; transfers the delivery tube 8, puts the sample in it to transfer the collected rubber sample 6 to the inspection room, wherein, in the opening of the delivery delivery tube 8 The lower end is provided with a sample storage plate 9, and has first and second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com