Control card test board

A control card and test bench technology, applied in general control systems, electrical test/monitoring, control/regulation systems, etc., can solve the problems of cumbersome manual testing steps and inability to fully test product performance, so as to reduce manual operation procedures and facilitate query effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

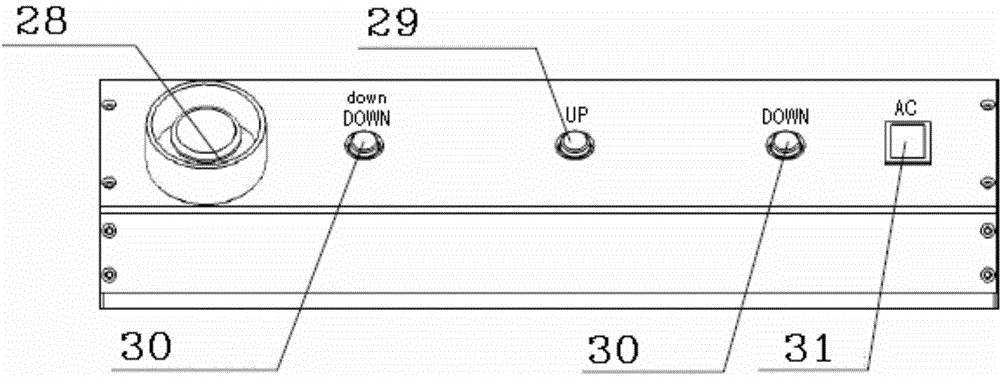

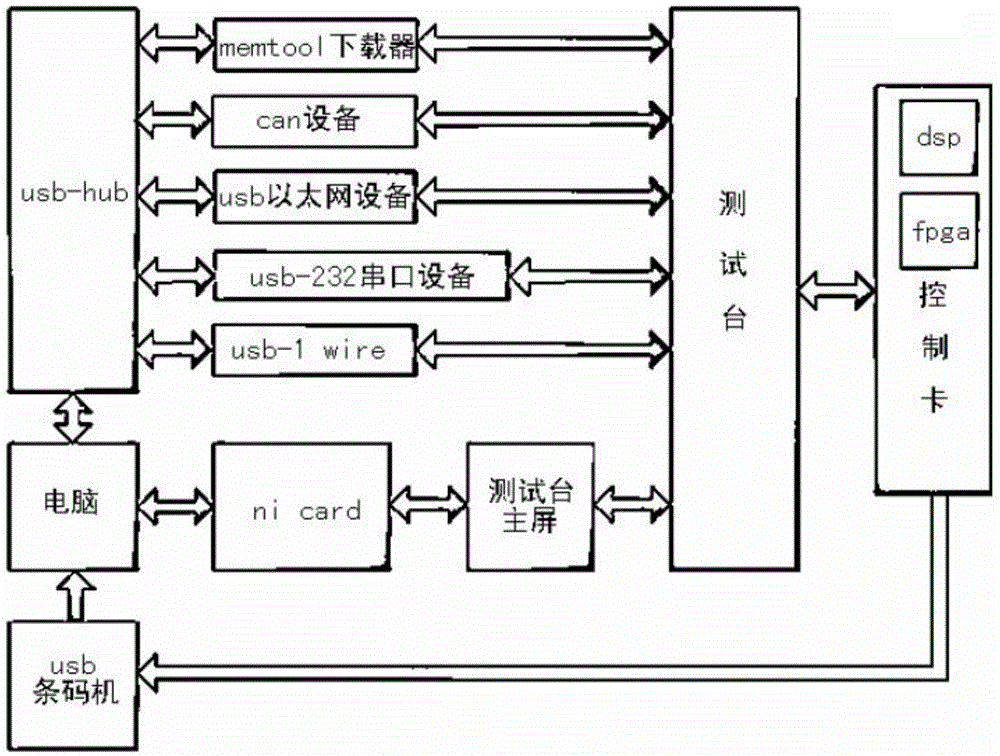

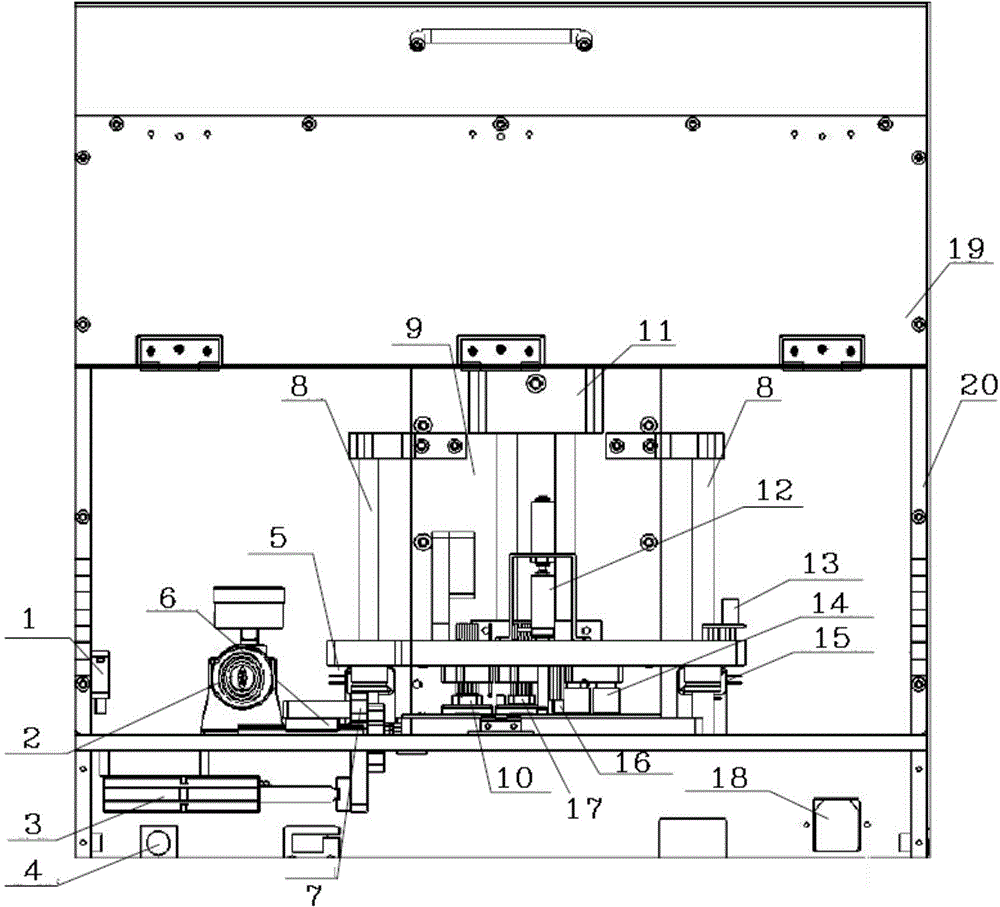

[0023] Such as Figure 1 ~ Figure 4 As shown, a control card test bench includes safety door cover detection switch 1, air pressure regulating valve 2, X-axis cylinder 3, air pressure input connector 4, X-axis cylinder right travel limit switch 5, X-axis guide rail slider 6, coding User port module 7, Y-axis cylinder guide column 8, Y-axis cylinder installation column 9, serial port module 10, Y-axis cylinder 11, electromagnet module 12, photosensitive detection module 13, network port connection module 14, Y-axis cylinder down limit switch 15, optical fiber conduction module 16, Can module 17, AC220V input socket 18, safety door 19, protective cover 20, X-axis cylinder solenoid valve 21, Y-axis cylinder solenoid valve 22, solenoid valve power supply 23 , test system power supply 24, auxiliary test circuit board 25, power socket 26, USB HUB27, power emergency stop switch 28, Y-axis cylinder up control switch 29, Y-axis cylinder down control switch 30, main power switch 31, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com