Professional glaze spraying six-axis robot

A six-axis robot and robot technology, applied in the field of robotics, can solve the problems of difficult technology absorption and production application, high price, complicated operation, etc., and achieve the effect of reliable chain transmission structure, easy maintenance and maintenance, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

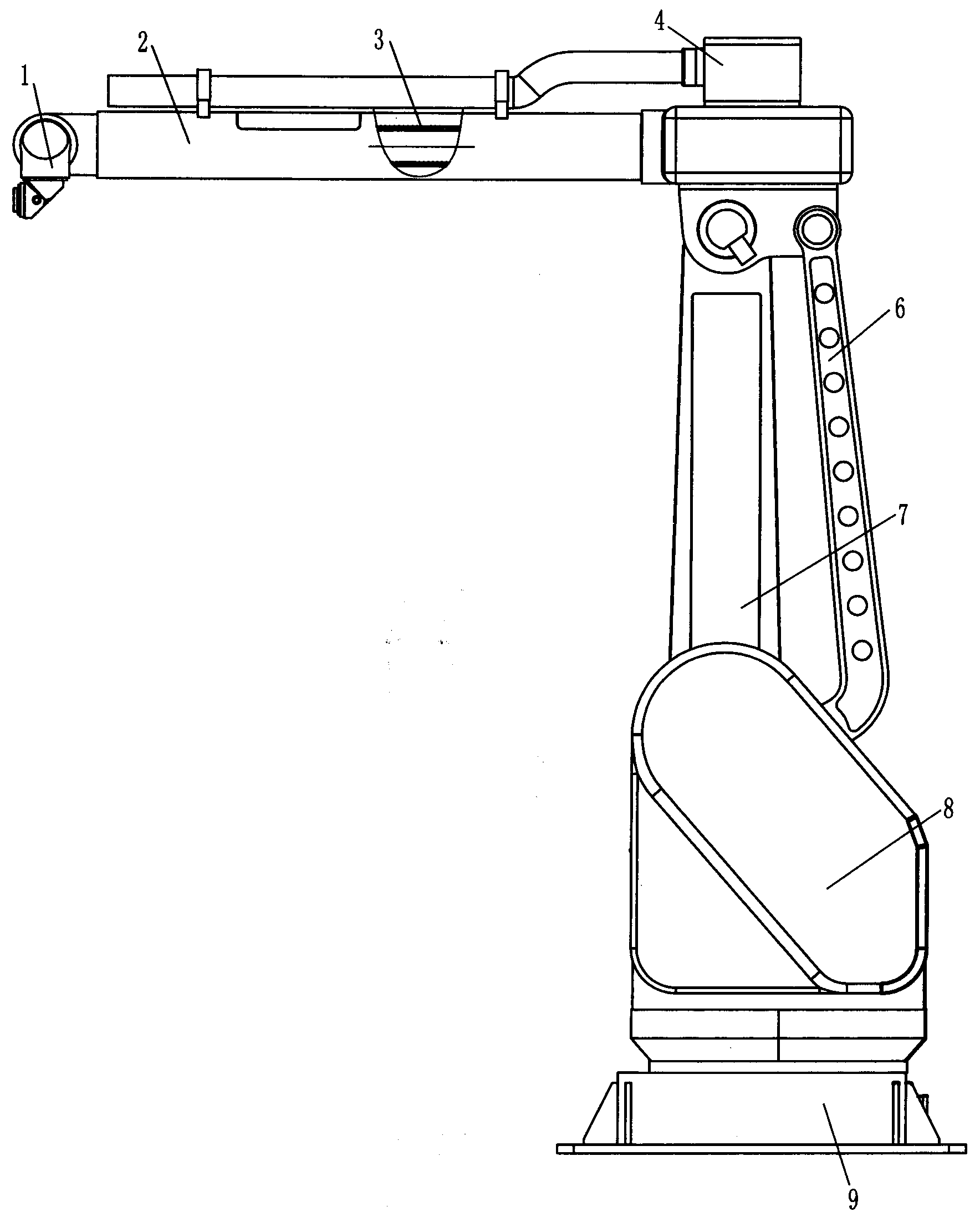

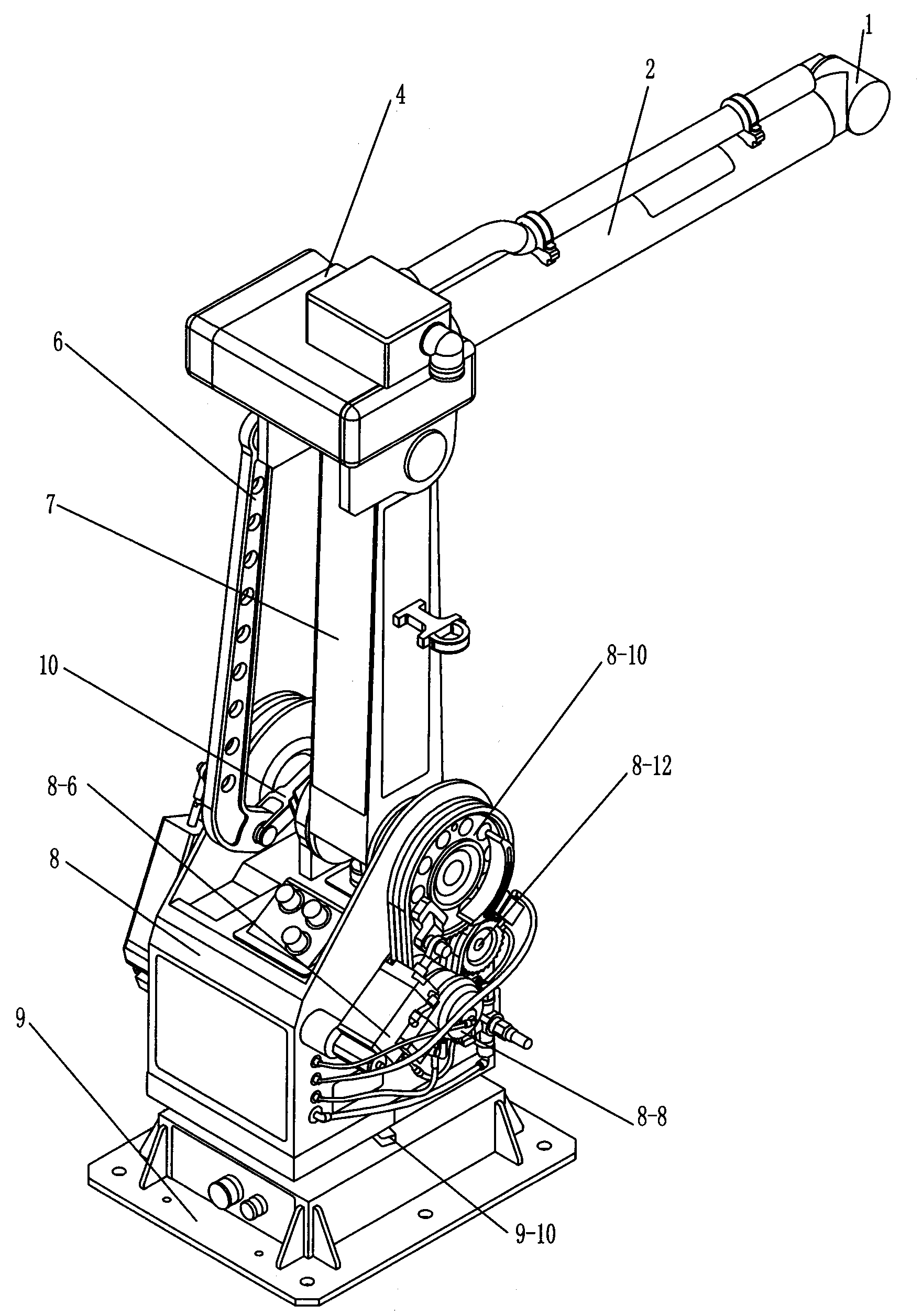

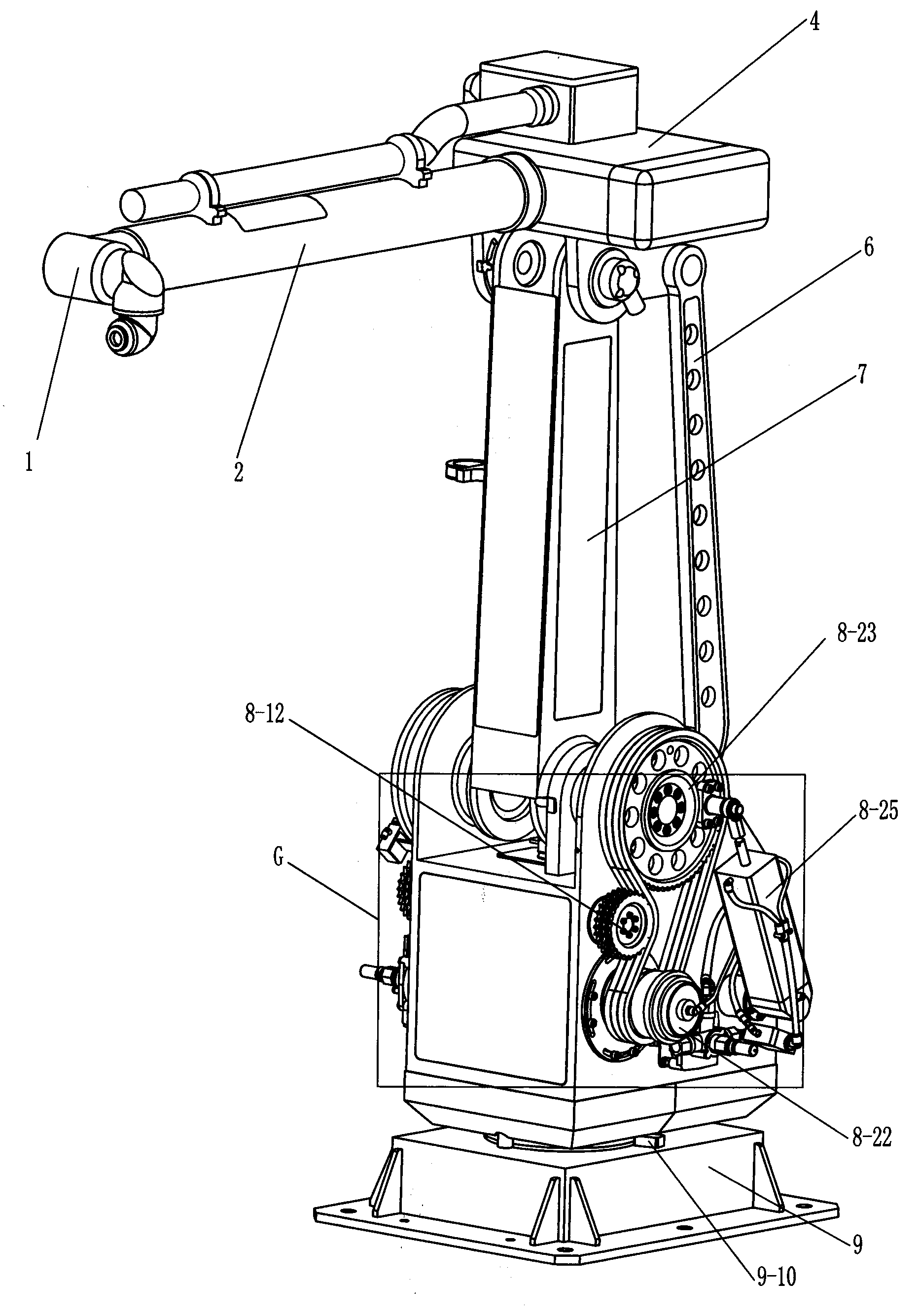

[0008] Specific implementation mode one: as Figure 1 ~ Figure 3 , Figure 5-c , Figure 9-c , Figure 9-d , 13As shown in a5a7d6-8f12-4b0c-9785-2798cfb40c79, the professional glaze spraying six-axis robot includes robot wrist 1, forearm 2, wrist transmission chain 3, four-five-six-axis seat assembly 4, three-axis drive link 6, large Arm assembly 7, two-three-axis box assembly 8, base assembly 9, three-axis drive bracket 10; four-axis motor 4-5 and five-axis motor 4-9 of the robot wrist 1 and four-five-six-axis seat assembly 4 and the input ends of the six-axis motors 4-13 are respectively connected by a wrist transmission chain 3, and the robot wrist 1 adopts an aspherical orthogonal transmission structure, which is the output end of the robot's four-axis, five-axis and six-axis; the robot wrist 1 and the small Between the arms 2 and between the small arm 2 and the four-five-six axle seat assembly 4 are sequentially connected; the upper part of the boom assembly 7 is conn...

specific Embodiment approach 2

[0009] Specific implementation mode two: as figure 1 , Figure 5-c , Figure 5-d , Figure 17 ~ Figure 19 As shown, in the professional six-axis robot for spraying glaze described in Embodiment 1, the wrist transmission chain 3 includes a four-axis transmission chain 3-1, a five-axis transmission chain 3-3, and a six-axis transmission chain 3-5; The four-axis transmission chain 3-1, the five-axis transmission chain 3-3 and the six-axis transmission chain 3-5 are arranged in parallel, and the four-axis motor 4-5 of the robot wrist 1 and the four-five-six-axis seat assembly 4 The input end is connected by a four-axis transmission chain 3-1; the input end of the five-axis motor 4-9 of the robot wrist 1 and the four-five-six-axis seat assembly 4 is connected by a five-axis transmission chain 3-3; the robot The input end of the wrist 1 and the six-axis motor 4-13 of the four-five-six-axis seat assembly 4 is connected through a six-axis transmission chain 3-5.

specific Embodiment approach 3

[0010] Specific implementation mode three: as Figure 1 ~ Figure 3 , Figure 6 , Figure 20 As shown, the professional glazing six-axis robot described in Embodiment 1 or 2, the boom assembly 7 includes a boom 7-2, two bearing glands 7-1; the boom 7-2 For a four-frame structure with a hollow cavity and closed surroundings, a bearing gland 7-1 is fixedly installed on two opposite sides of the upper end of the boom 7-2, respectively.

[0011] Specific implementation mode four: as Figure 1 ~ Figure 3 , Figure 5-a~Figure 5-d , Figure 13 , Figure 20 As shown, the professional glaze spraying six-axis robot described in Embodiment 1, the four-five-six-axis seat assembly 4 includes a four-five-six-axis seat 4-1, a four-axis sprocket II4-2, and a four-axis connecting flange 4-3, four-axis reducer 4-4, four-axis motor 4-5, five-axis sprocket II4-6, five-axis connecting flange 4-7, five-axis reducer 4-8, five-axis motor 4-9 , Six-axis sprocket II4-10, six-axis connecting flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com