Dual-axis automatic grabbing manipulator device

A grabbing manipulator and automatic technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of reducing manufacturing costs, compact space requirements, etc., to achieve the effect of ensuring rigidity, realizing light weight and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

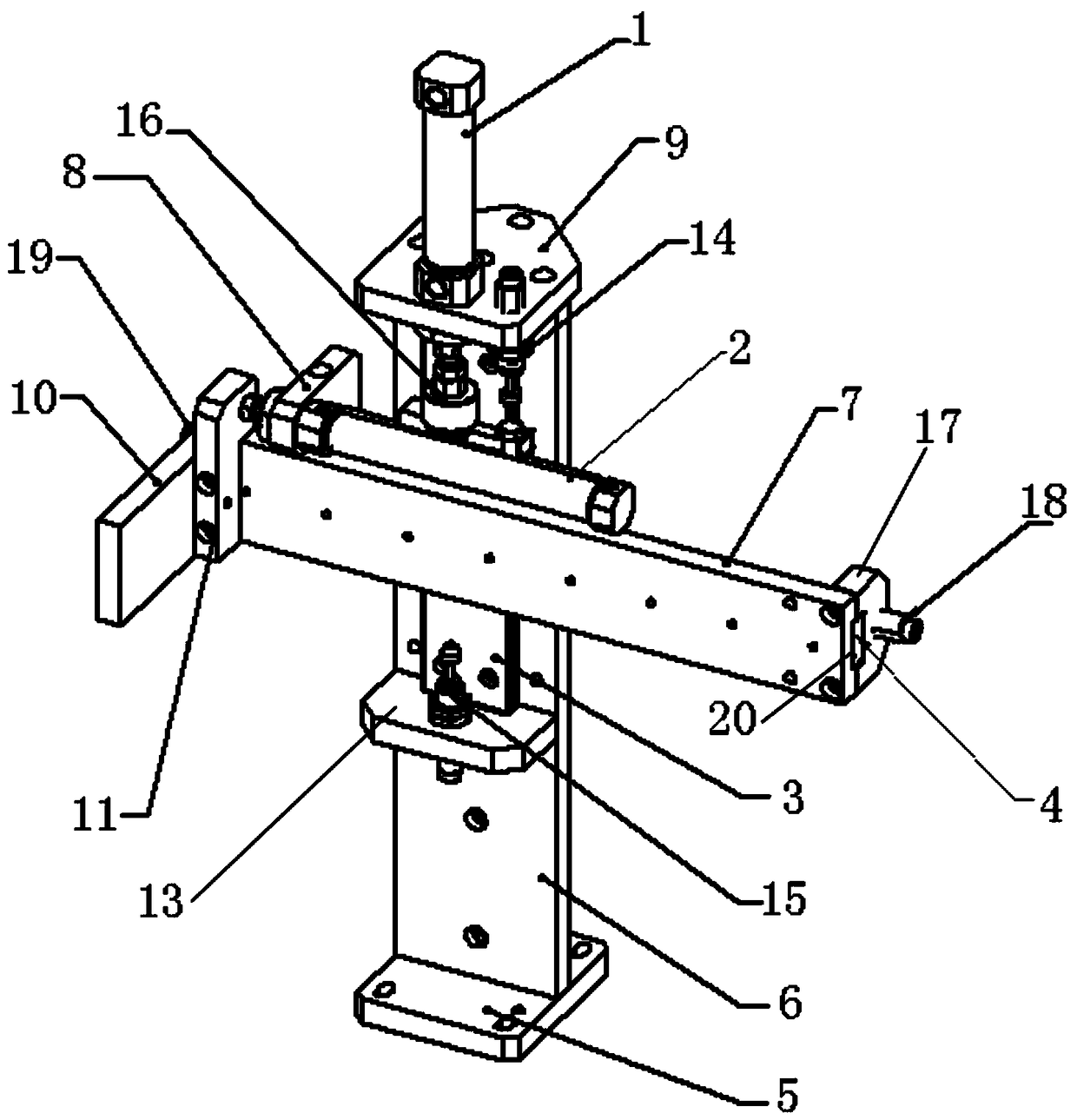

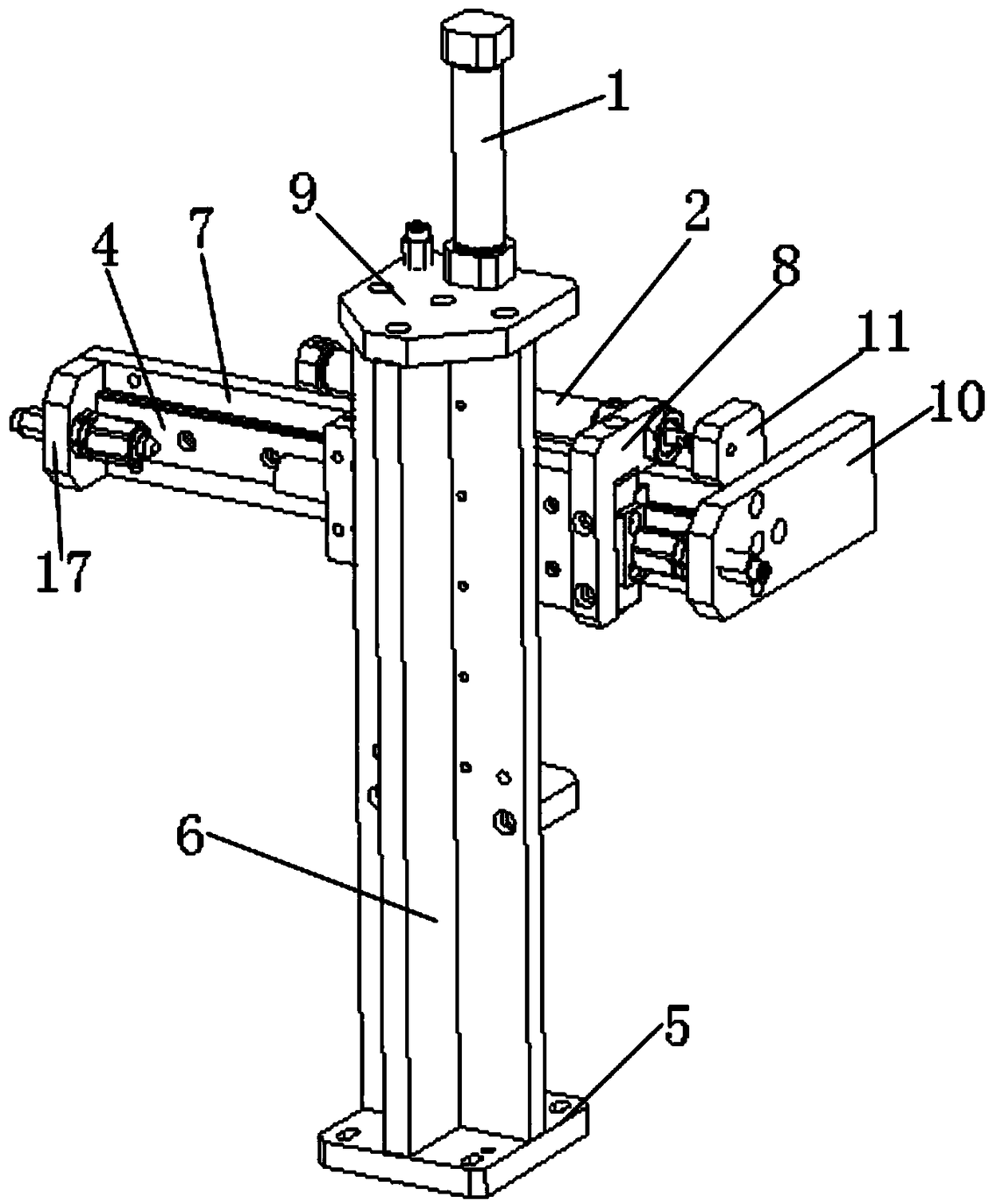

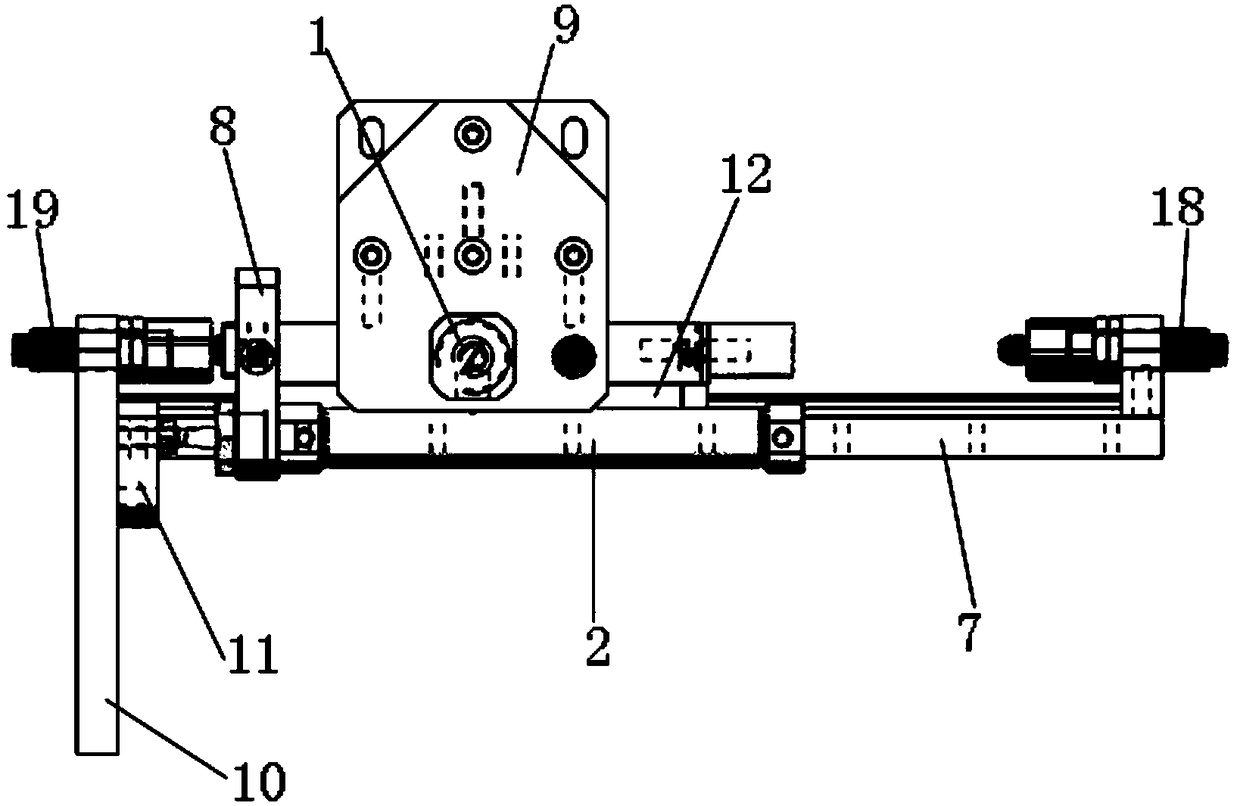

[0027] Such as Figure 1-5 The two-axis automatic grabbing manipulator device shown includes a vertical motion cylinder 1, a front and rear motion cylinder 2, a Z-axis linear guide rail 3, an X-axis linear guide rail 4, a base 5, a base support plate 6, and an X-axis guide rail fixing plate 7 , X-axis cylinder fixing plate 8, Z-axis upper base plate 9, grasping fixing plate 10, X-axis pushing plate 11 and slider 12, the base support plate 6 is vertically arranged on the upper end surface of the base 5, so The upper end of the base support plate 6 is provided with a Z-axis upper base plate 9, and the base support plate 6 and the Z-axis upper base plate 9 are vertically arranged, and the up and down movement cylinder 1 is arranged on the Z-axis upper base plate 9, and the Z-axis The axial linear guide rail 3 is arranged on the side wall of the base support plate 6, the cross section of the base support plate 6 is T-shaped, the slider 12 is arranged on the Z-axis linear guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com