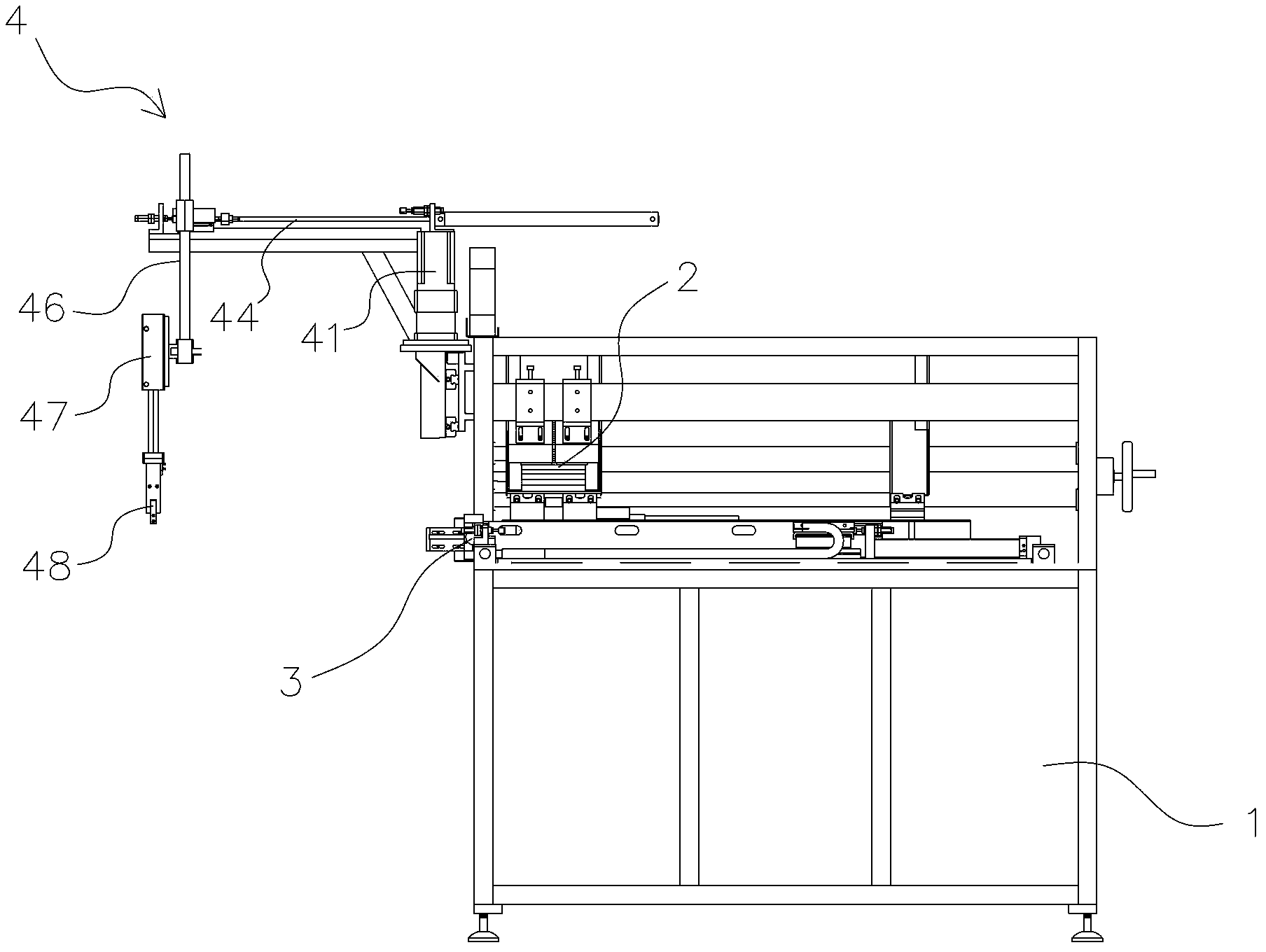

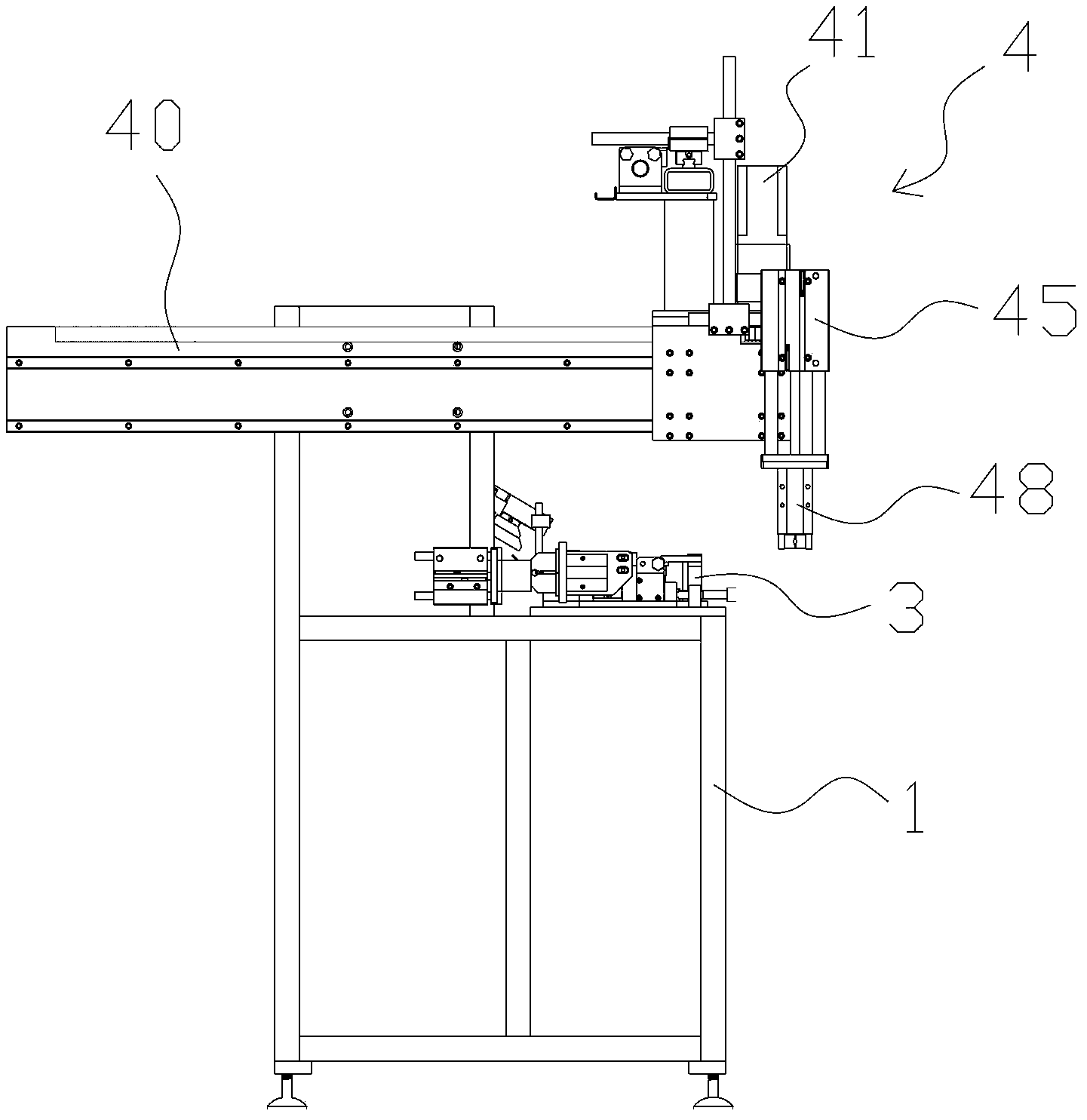

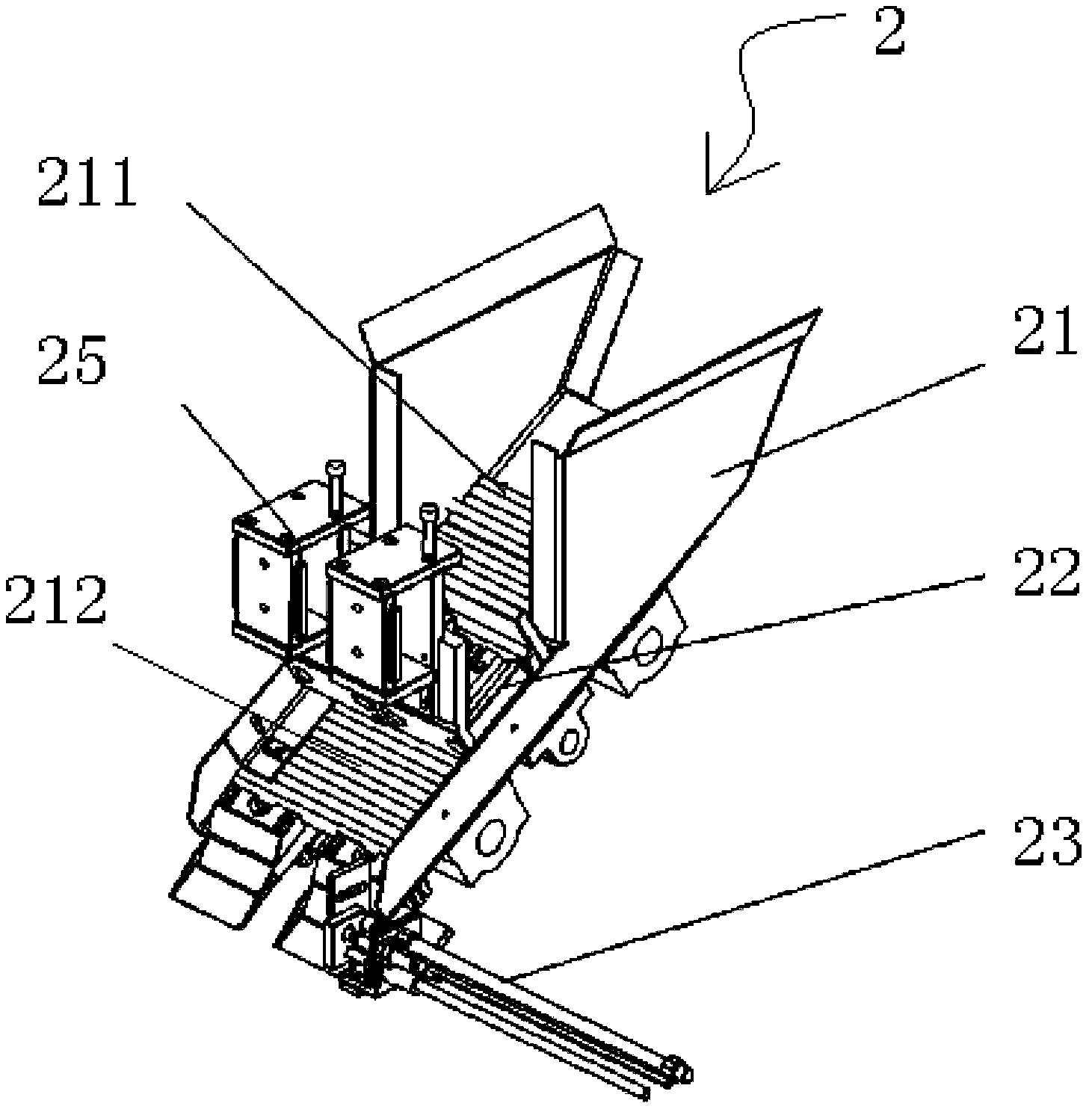

Pipe bending machine loading and unloading manipulator

A technology of pipe bending machines and manipulators, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of high labor intensity, potential safety hazards, and low work efficiency, and achieve compact structure, low operating cost, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the specification, there is no special limitation on the size of the loading and unloading manipulator of the pipe bending machine, and it can be properly adjusted according to actual needs.

[0022] In the description, all the direction descriptions are only for the convenience of description and help readers to understand the present invention, rather than to limit the present invention, in particular, it cannot be understood as a limitation on the application of the position and orientation of the present invention, because if it is stated in reverse , the position and orientation will also be reversed.

[0023] The machine body, storage bin system, feeding system, and unloading system in the manual can be programmed and controlled by single-chip microcomputers or combined with single-chip microcomputers. Of course, they can also be controlled by PLC. PLC is a programmable logic controller. The full name in English is: Programmable Logic Controller, which uses a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com