Efficient stacker crane used inside van type truck

A van and palletizer technology, applied in the field of palletizers, can solve problems such as low economic benefits, large external space, and high labor intensity, and achieve convenient and flexible operation, wide application range, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

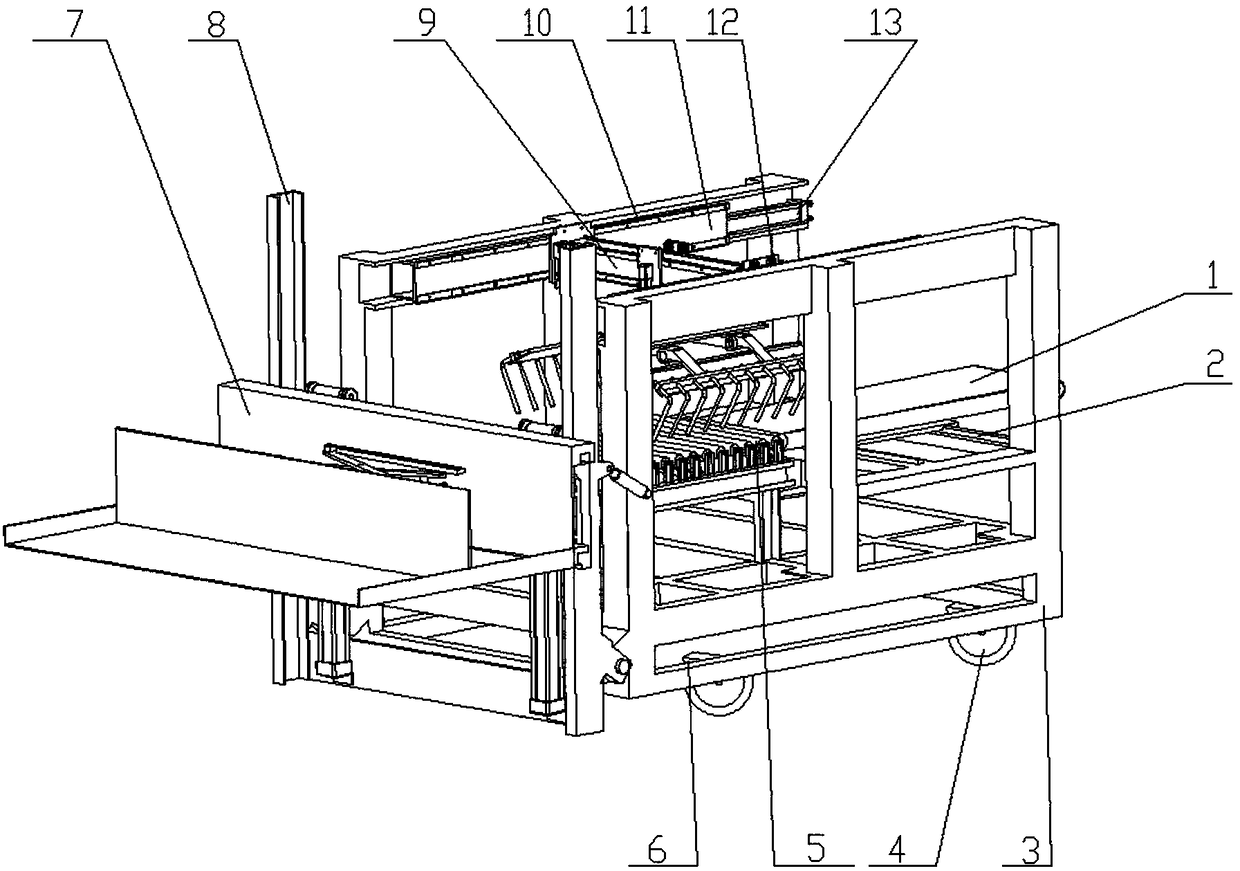

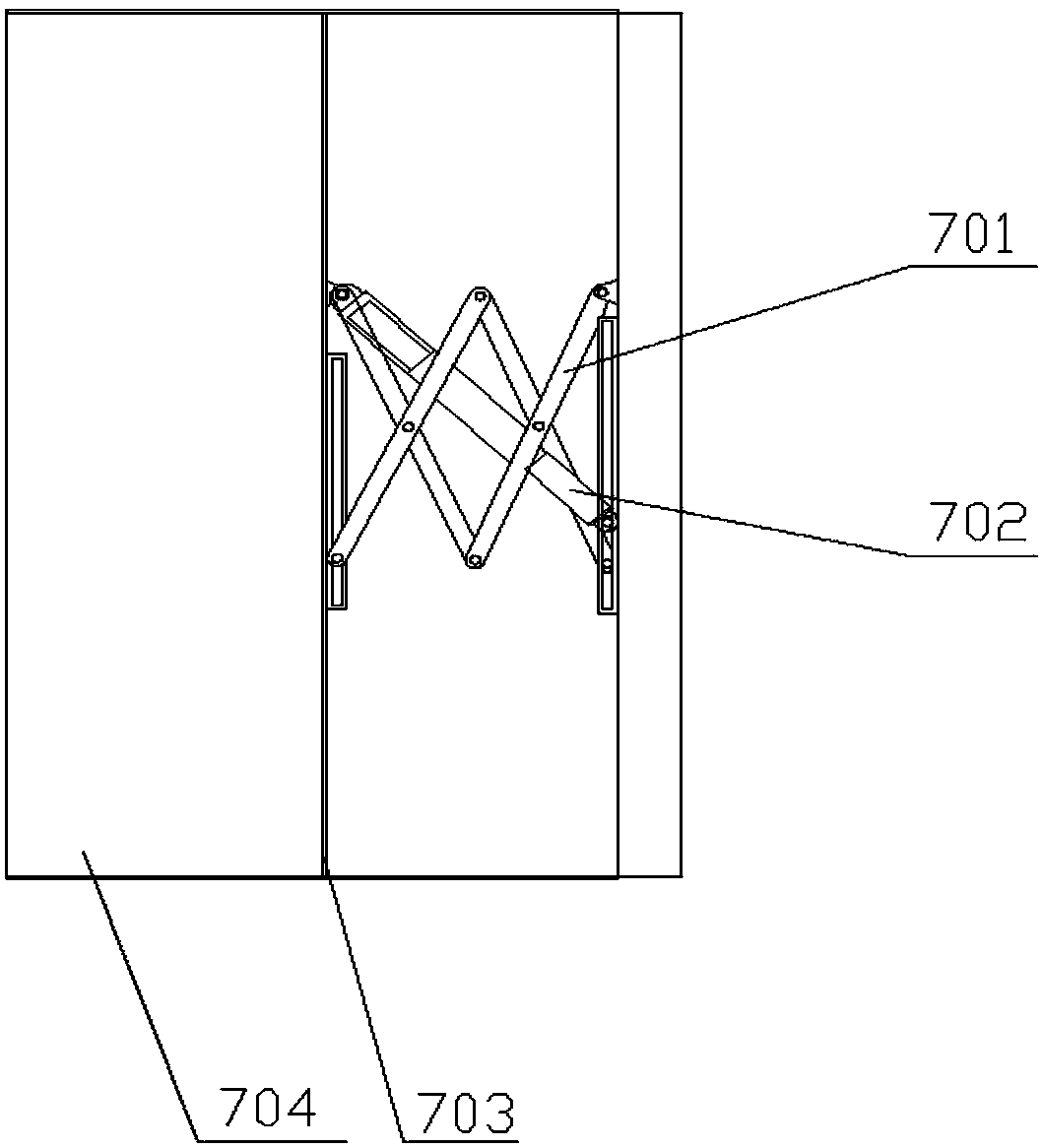

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 A high-efficiency palletizer for the interior of a van is shown, including a feeding device 1, a feeding slide rail 2, a vehicle frame 3, a bottom wheel 4, an unpowered roller 5, a servo motor 6, and an unloading device 7 , lifting mast 8, feeding device 9, X-axis track 10, X-axis beam 11, X-axis roller 12, X-axis cylinder 13.

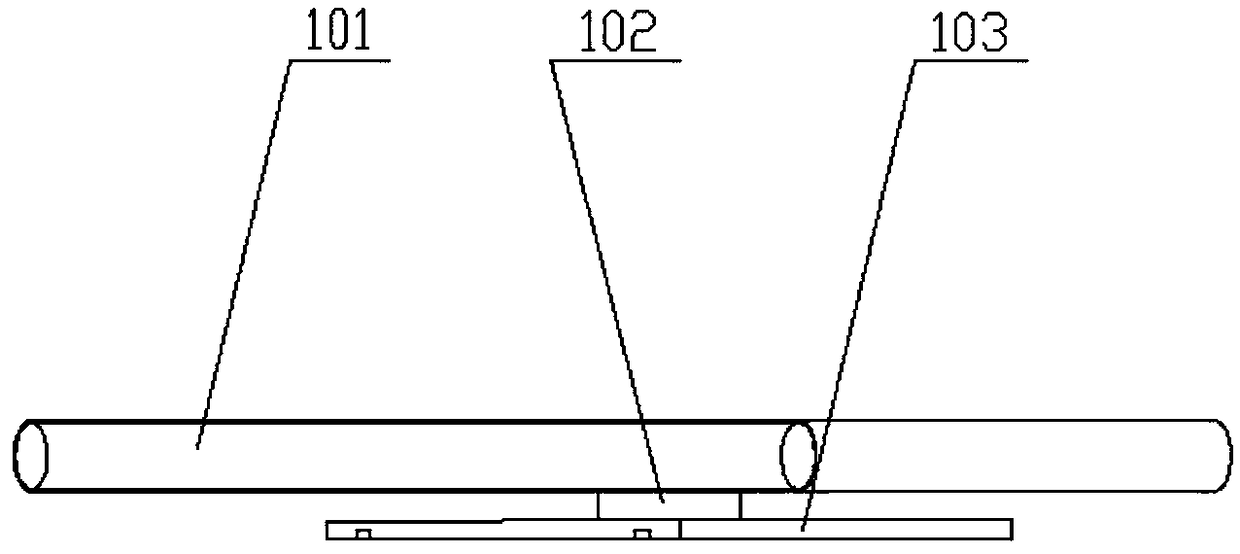

[0024] The bottom wheel 4 and the servo motor 6 are installed coaxially, and are fixed on the bottom of the vehicle frame 3 by bolts, the vehicle frame 3 is equipped with the feeding slide rail 2, and the feeding device 1 passes through the The feed slide rail 2 is connected with the vehicle frame 3, the feed device 1 includes a conveyor belt 101, a feed bearing 102, and a feed slide 103, and the conveyor belt 101 is installed on the feed conveyor 102 through the feed bearing 102. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com