Lens testing focusing machine

A focusing machine and lens technology, which is applied in optics, instruments, photography, etc., can solve the problems of large space occupation, affecting the angle of view of the lens, intelligent single test or focusing, etc., so as to improve work efficiency, realize focusing processing, and realize The effect of testing and focusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

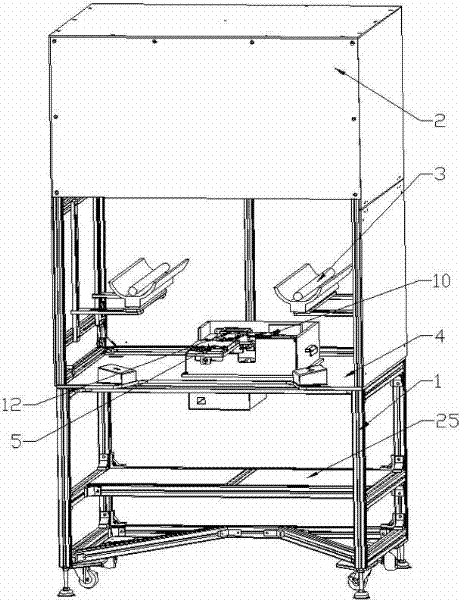

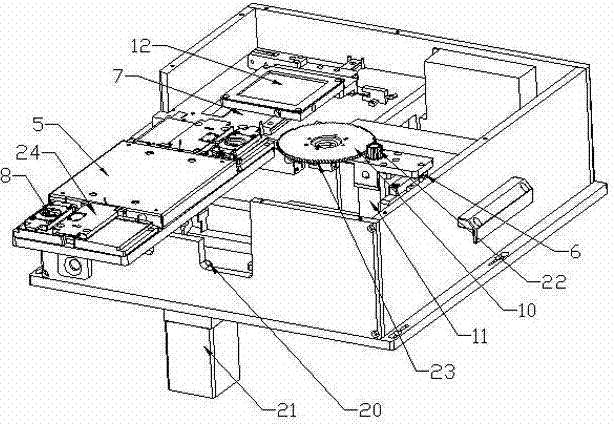

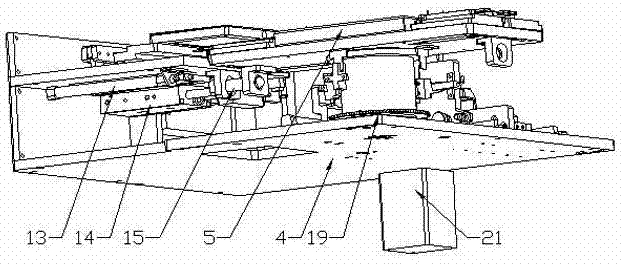

[0022] Such as Figure 1 to Figure 7 As shown, the present invention includes a frame 1, a light box 2, a focusing plate (not marked in the drawings) arranged in the light box 2, a light distribution lamp 3, a reference plate 4 and a peripheral host (not shown in the drawings). marked). A swing table 5 , an X-axis focusing table 6 , and a Y-axis test table 7 are arranged on the reference plate 4 . Two lens trays 8 are arranged diagonally on the oscillating table 5, and the oscillating table 5 can be rotated. A tray cover 24 is provided on the lens tray 8 . The X-axis focusing table 6 is driven by the X-axis cylinder 9 to reciprocate in the X-axis direction. A focusing ring 10 is provided on the X-axis focusing table 6 , and the focusing ring 10 is driven to rotate by a focusing motor 11 provided on the X-axis focusing table 6 . The focus ring 10 is arranged on a support cylinder (not marked in the drawings). A white screen 12 is arranged on the Y-axis test table 7 , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com