Lifting-clamping-type vacuum chuck clamp and use method thereof

A vacuum suction cup, clamping type technology, applied in the direction of chucks, manufacturing tools, manipulators, etc., can solve the problems of loss, easy damage, and inability to identify goods, and achieve the effect of reducing weight and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

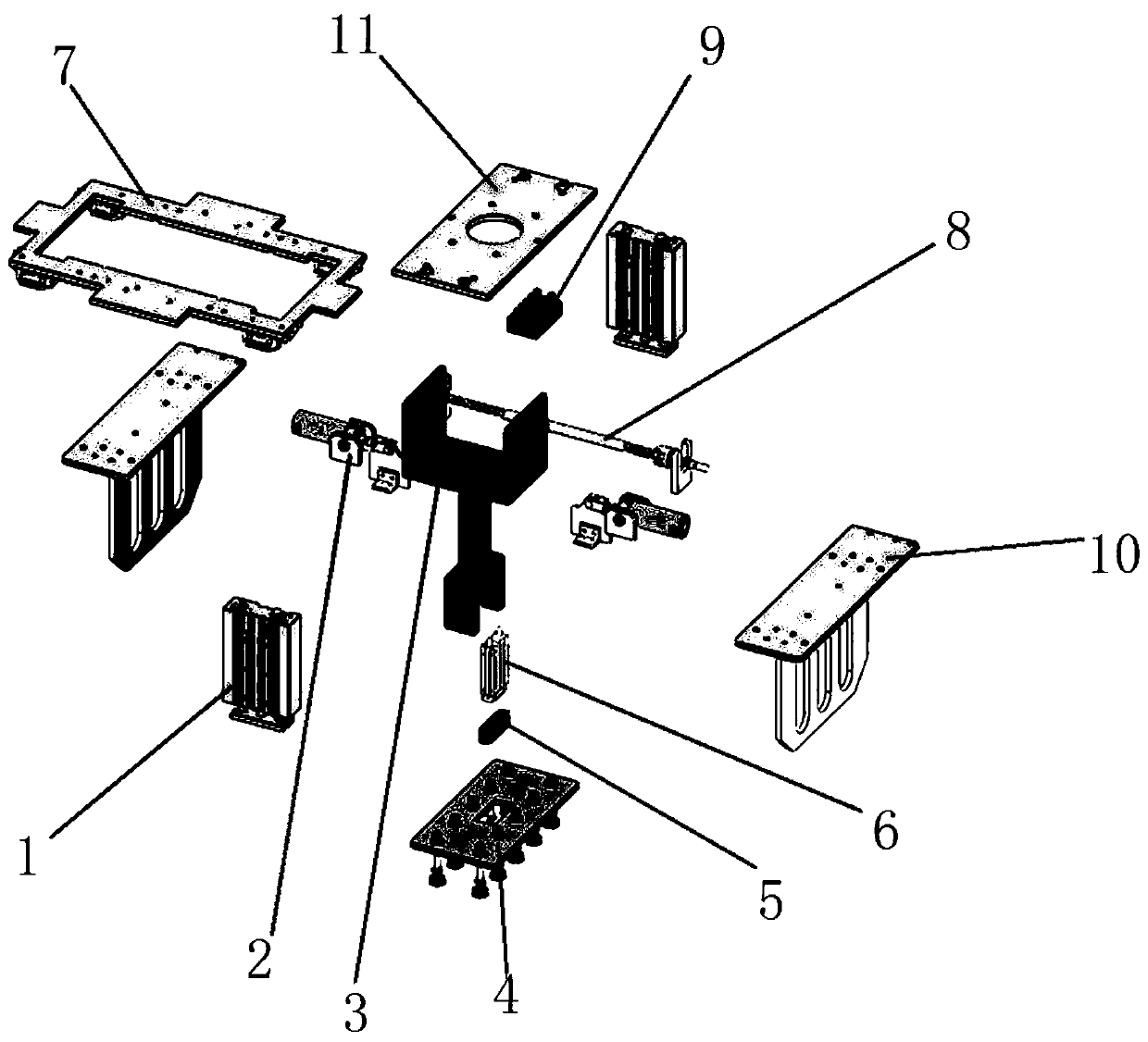

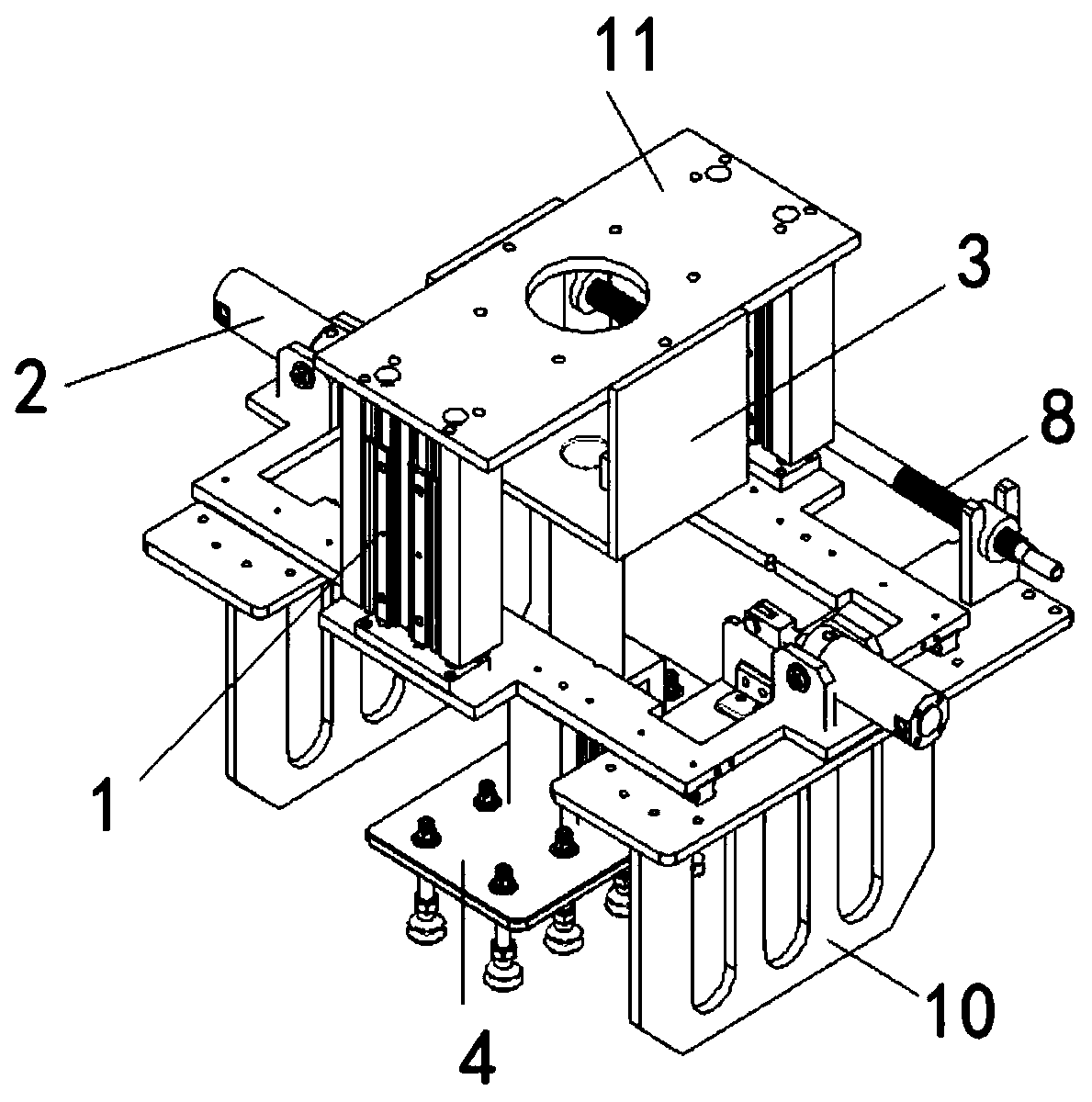

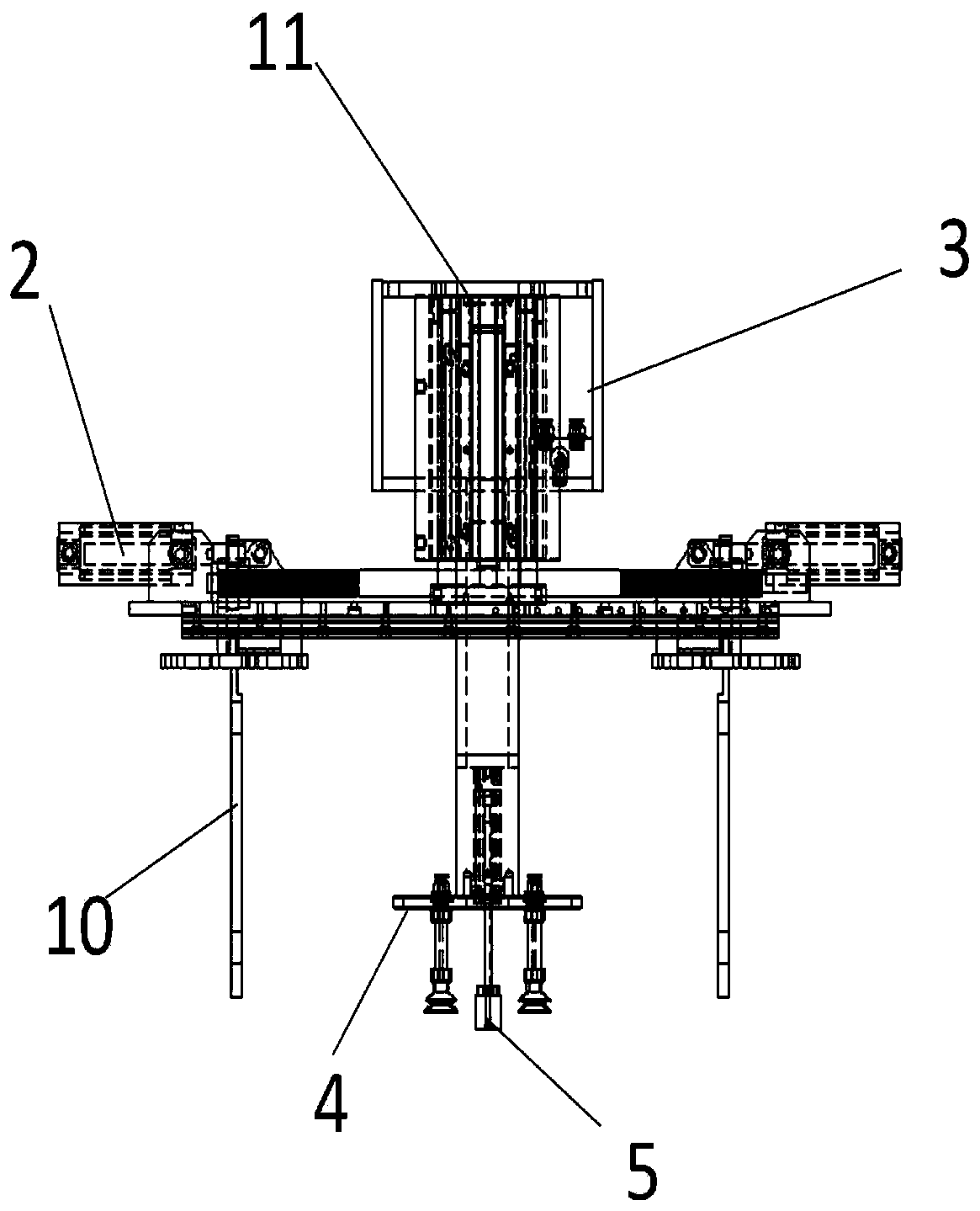

[0039] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0040] Such as Figure 1 to Figure 3 As shown, the lifting and clamping vacuum suction cup fixture provided by the embodiment of the present invention includes: a three-axis cylinder 1, a one-way cylinder 2, a mounting frame 3, a suction cup 4, a 3D camera 5, a camera three-axis cylinder 6, a rail frame 7, and a spring Rod 8, vacuum system related components 9, splint 10, clamp connection plate 11.

[0041] The middle of the mounting frame 3 is provided with a connecting pipe, and the upper and lower ends of the connecting pipe are welded with vertical mounting grooves. The lower end of the mounting frame 3 is fixed with a suction cup 4 by bolts; The lower sides of both ends are connected with a three-axis cylinder 1 by bolts, the lower end of the three-axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com