Odd-number polar plate group-collocating mechanism of flaker

A packaging machine and plate technology, which is applied in sustainable manufacturing/processing, climate sustainability, secondary battery manufacturing, etc., can solve the problem of insufficient matching efficiency, and achieve simple structure, neat matching and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

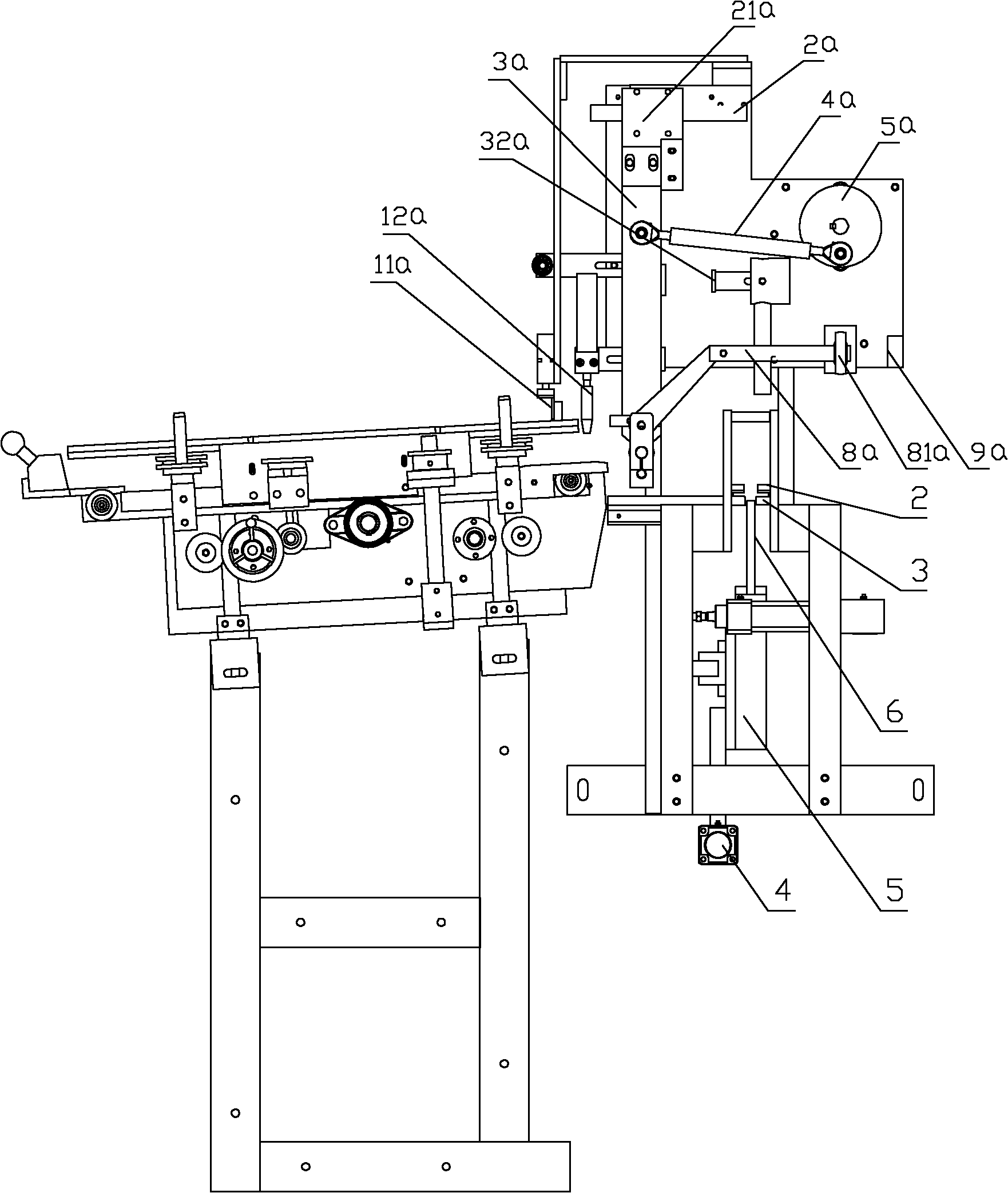

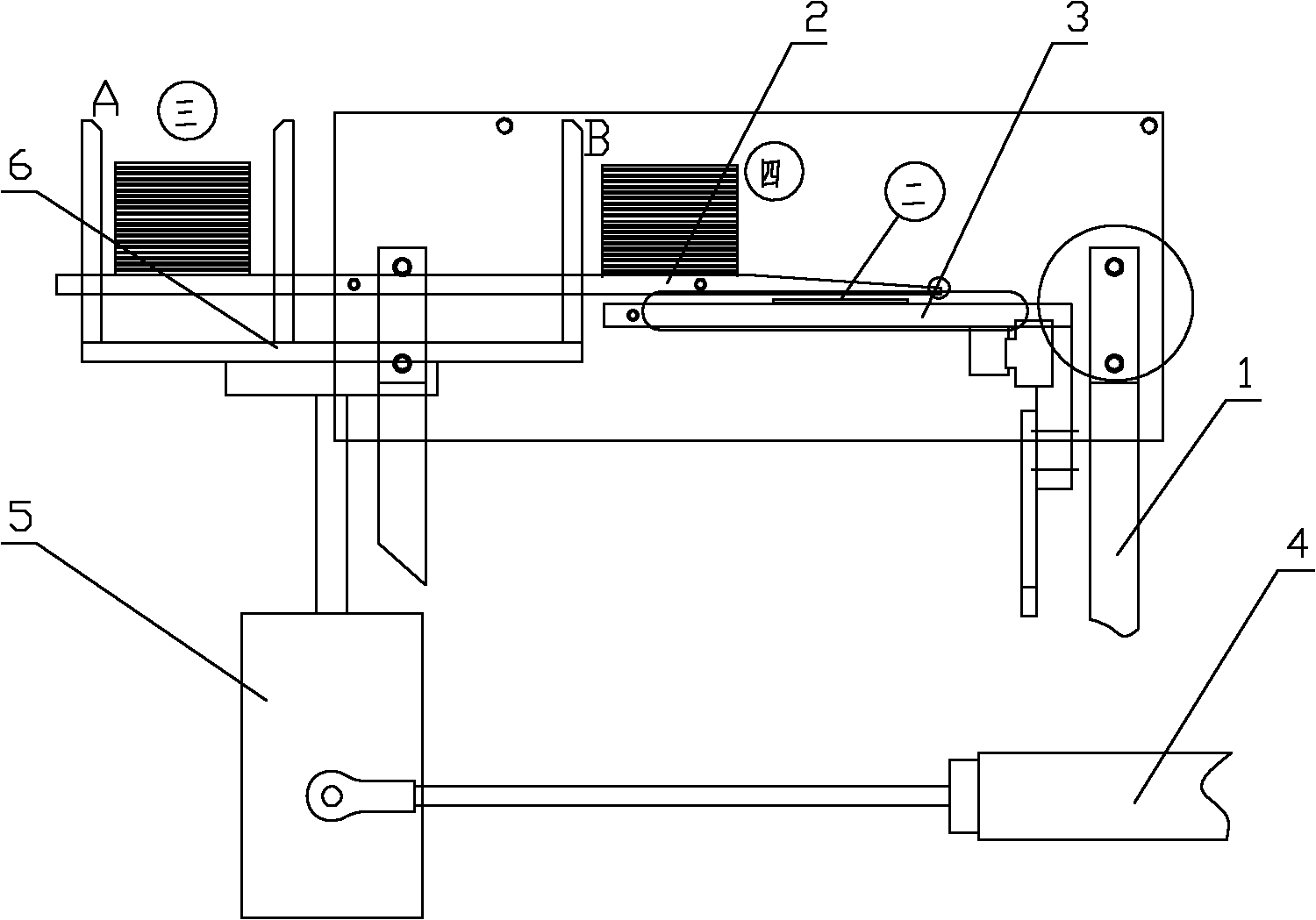

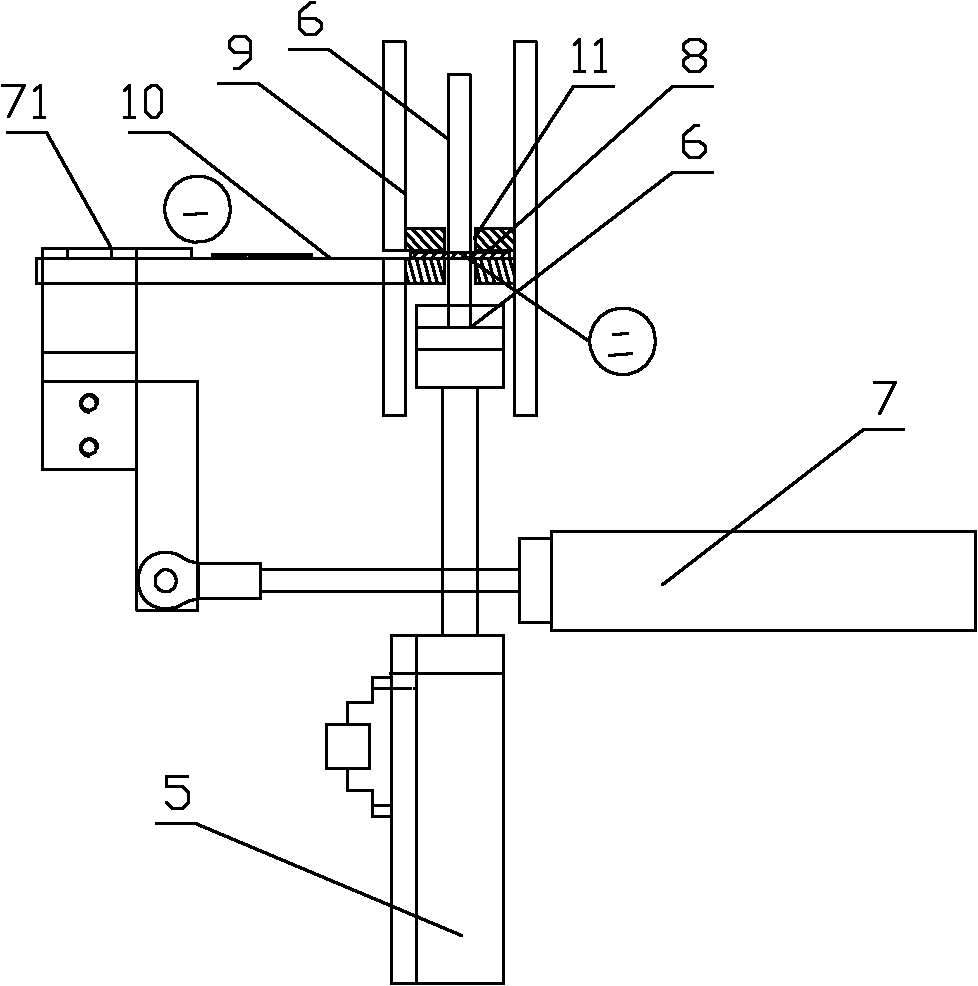

[0026] Such as Figure 1 to Figure 10 As shown, it is an embodiment of the odd-numbered pole plate grouping mechanism of the wrapping machine of the present invention, including a bracket 1, and the upper part of the bracket is provided with a horizontal upper guide rail 2 and a lower guide rail 3, and a supply plate is provided between the upper guide rail and the lower guide rail. The gap 8 passing horizontally, the lower part of the support is provided with an X-axis cylinder 4 that slides back and forth, the X-axis cylinder is connected with a Z-axis cylinder 5 that slides up and down, and the upper part of the Z-axis cylinder is provided with a push rod mechanism 6. The middle part of the upper guide rail and the lower guide rail is provided with a chute 11 for the push rod of the push rod mechanism to pass through and push the pole plate to move back and forth. The side of the horizontal panel is provided with a pusher mechanism to push the pole plate on the horizontal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com