Medical waste crushing device

A crushing device, medical waste technology, applied in metal processing, grain processing, solid waste removal, etc., can solve the problems of crushing, disposable infusion tubes wrapped on the crushing roller, poor crushing effect, etc., to increase the crushing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

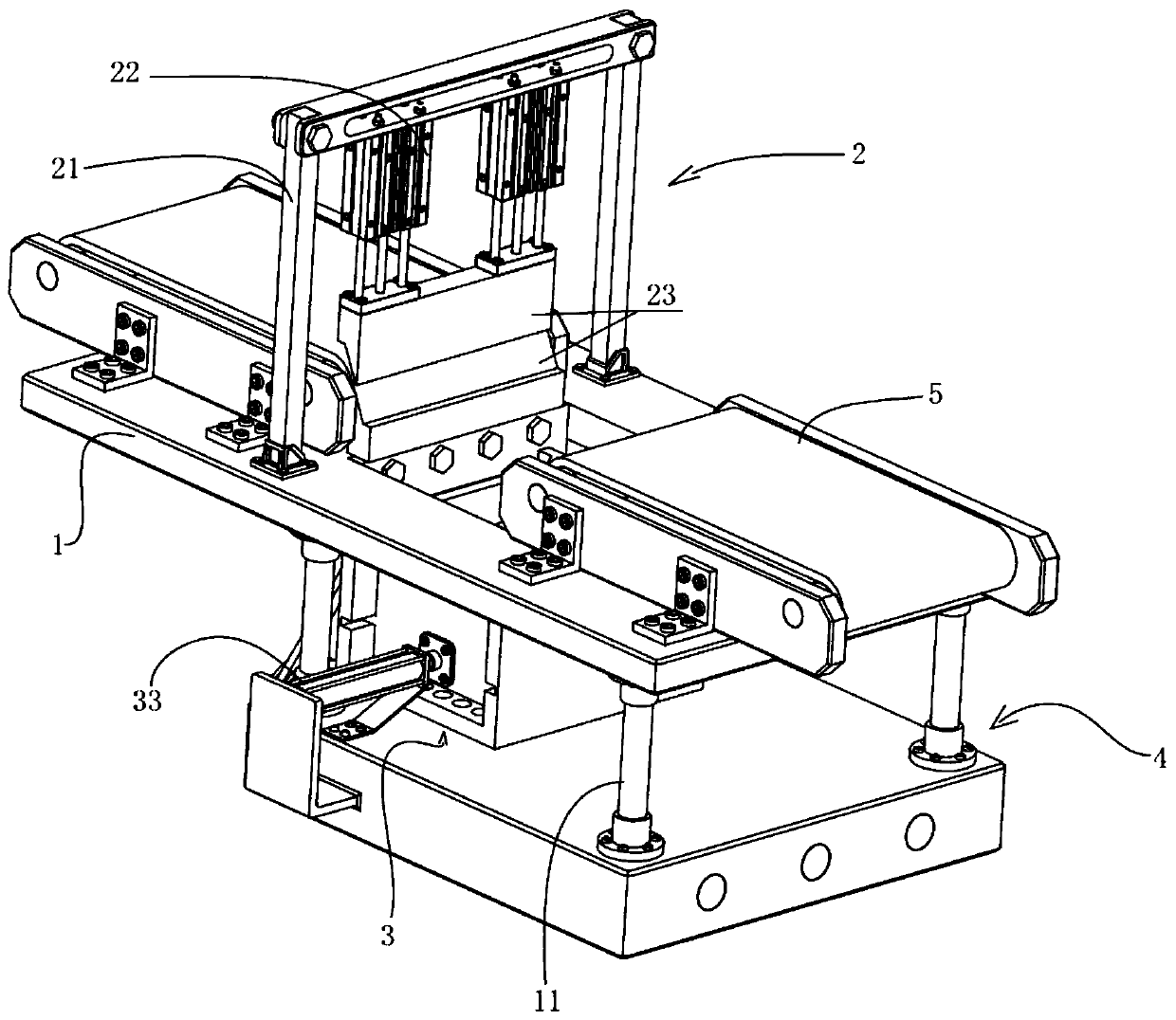

[0027] see Figure 1 to Figure 5 , the present invention provides a technical solution:

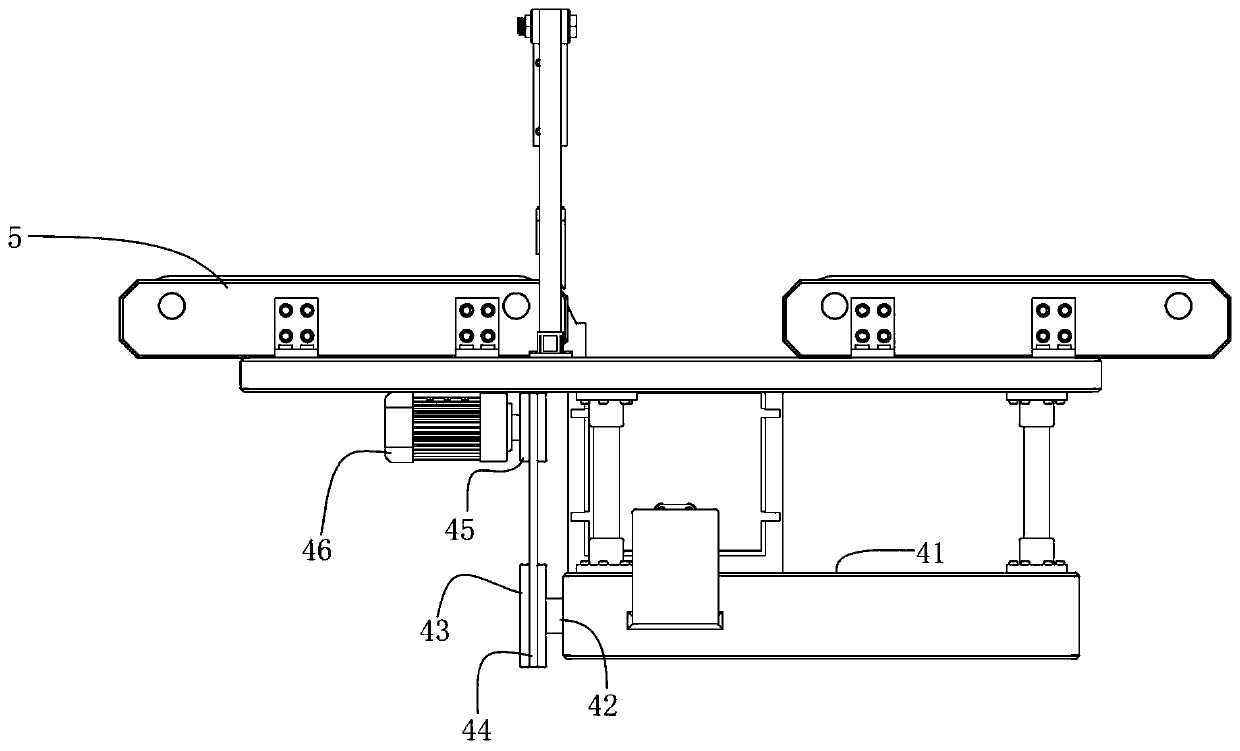

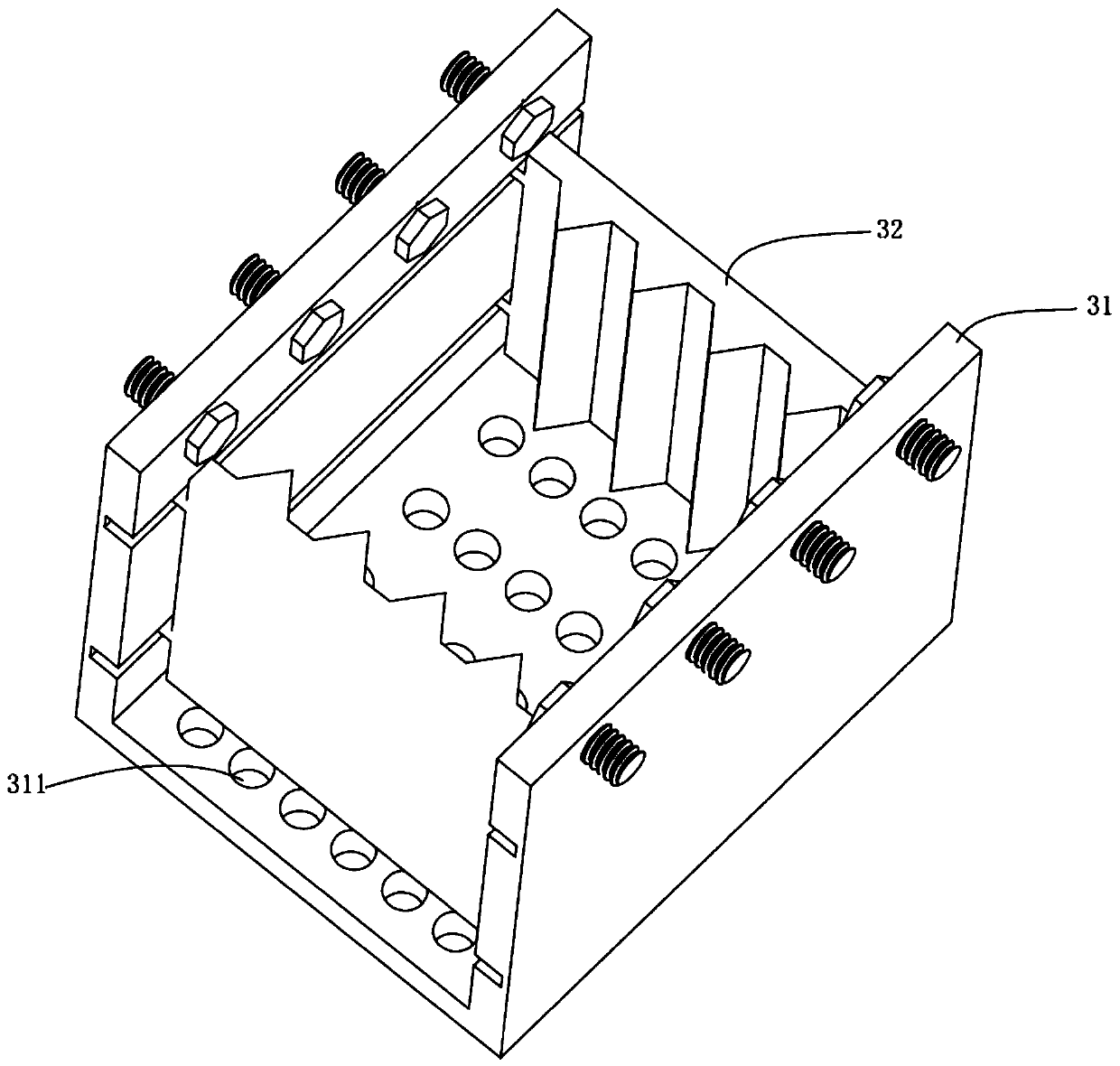

[0028] A medical waste crushing device, comprising a bottom plate 1, a cutting mechanism 2, an extrusion mechanism 3, a crushing mechanism 4 and a conveyor belt 5, wherein:

[0029] The cutting mechanism 2 includes a support 21, a three-axis cylinder 22 and a cutting knife 23, the support 21 is fixedly installed on the base plate 1 by bolts, two three-axis cylinders 22 are installed on the support 21 by bolts, and one of the two cutting knives 23 cuts Knife 23 is installed on the power output ends of two three-axis cylinders 22 by bolts, and another cutting knife 23 is installed on the base plate 1 by bolts, and cutting knives 23 are all fixed by bolts so as to facilitate replacement, wherein the two cutting knives 23 The blades are opposed to each other and placed alternately between the blades, forming a scissors shape between the two cutting knives 23, and the two conveyor belts 5 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com