Rotating cutter bit assembly having hardfaced block and wear washer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

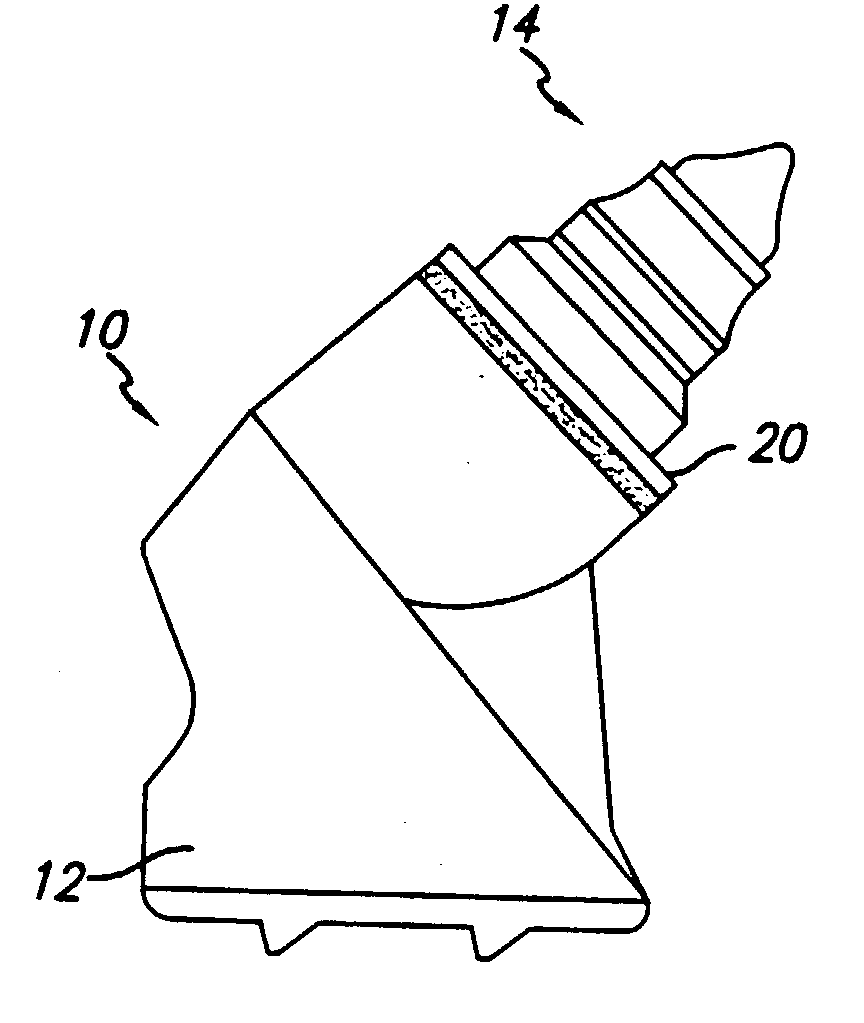

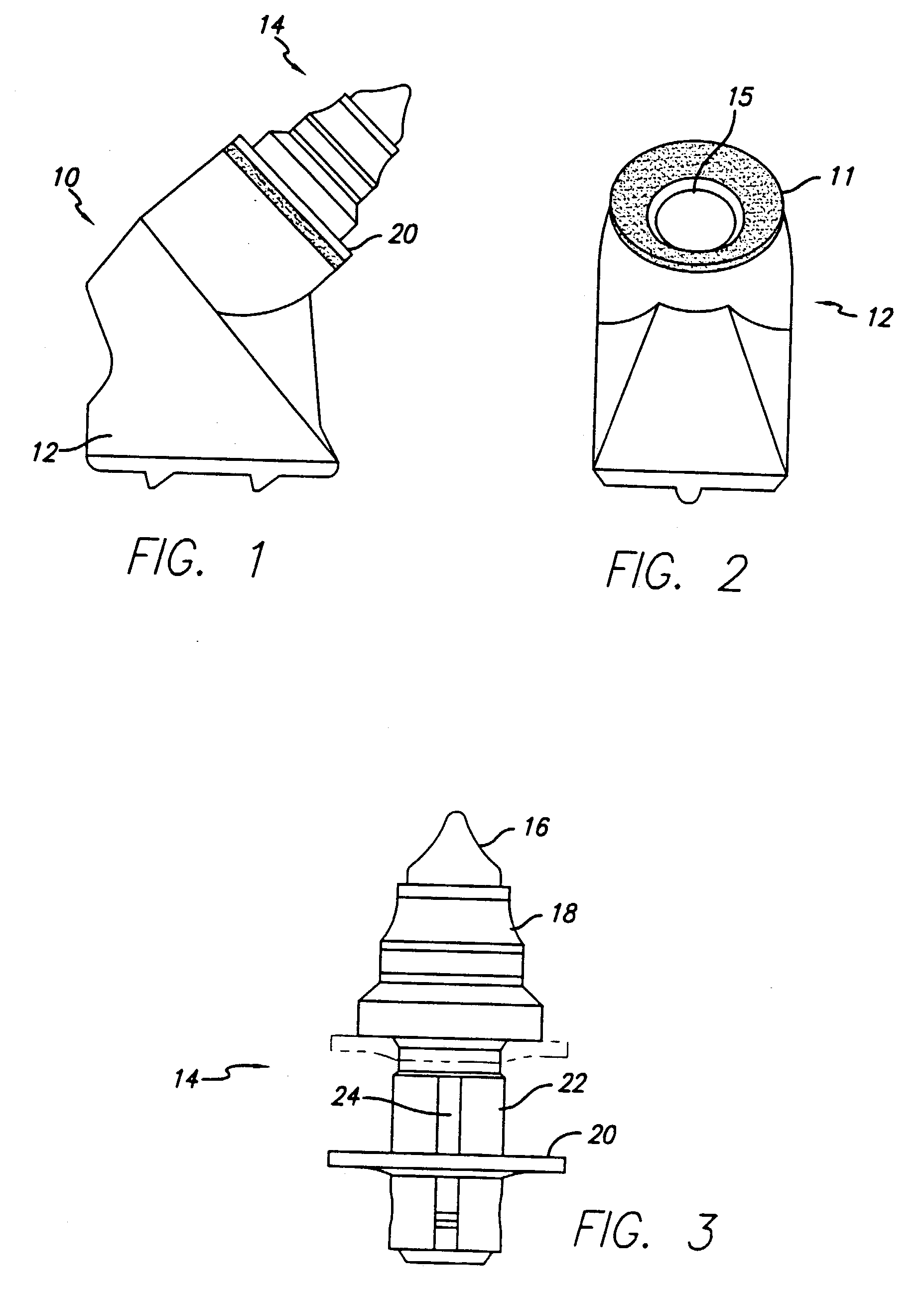

[0018] The cutter block assembly 10 of the present invention is illustrated in FIG. 1. The cutter block assembly 10 includes a holder block 12 and a rotatable cutter bit 14 fixed therein. As best seen in FIG. 2, the top face 11 of the block has a hardfacing material deposited thereon represented by the speckled / shaded grit.

[0019] The cutter bit assembly is best shown in FIG. 3. The cutter bit assembly includes a cutter body having an integral conical head 18 and shaft 24, cutting tip 16, a retainer 22 and a bearing washer 20. The cutter bit assembly 14 is first inserted and manually knocked into the bore 15 of the holder block, typically with a hammer. The retainer sleeve 22 is made from Spring Steel that is held in a compressed loaded position by the holding washer 20 as shown in FIG. 3. In the compressed loaded position the external diameter of the sleeve is less than the internal diameter of the bore. When the cutter bit assembly 14 is hammered into the bore 15 of the holder bloc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com