Resin bonder wire saw

A binder and resin technology, applied in the direction of grinding machines, drilling/drilling equipment, drilling tool accessories, etc., can solve the problems of core wire diameter change, wire saw cutting workpiece accuracy deterioration, etc., to achieve improved accuracy, improved efficiency, high The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, embodiments according to the present invention will be described with reference to the accompanying drawings.

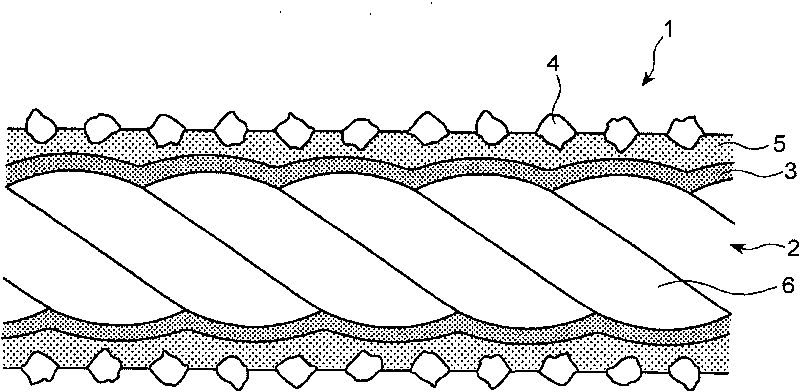

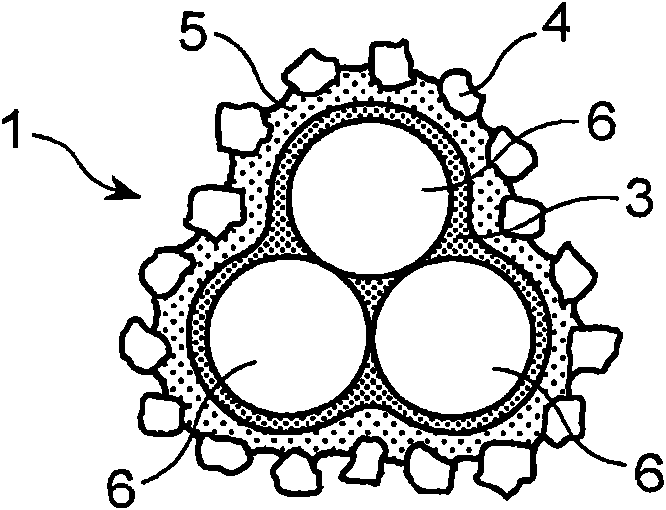

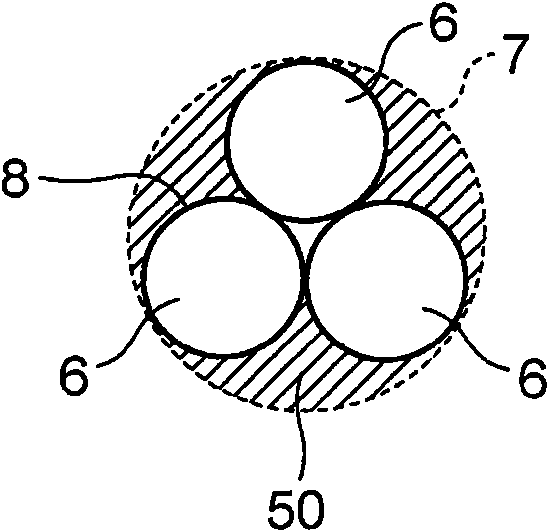

[0049] figure 1 is a longitudinal sectional view of a resin bond wire saw 1 according to an embodiment of the present invention, Figure 2A is a transverse sectional view of the resin bond wire saw 1, Figure 2B shows the circumcircle of the individual wires that make up the core, Figure 2C is a transverse sectional view of the core wire and the first resin layer;

[0050] will be referred to below figure 1 , Figure 2A to Figure 2C The resin bond wire saw 1 according to the present invention will be described.

[0051] Such as figure 1 and Figure 2A As shown, the resin bond wire saw 1 includes a core wire 2 composed of a plurality of single wires 6 twisted with each other, a first resin layer 3 made of a first resin and surrounding the core wire 2, and a second The second resin layer 5 is made of resin and surrounds the first resin laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com