Electroplating diamond fretsaw with grinding materials controllably distributed and preparation method

A technology for electroplating diamond and diamond, applied in metal sawing equipment, metal processing equipment, stone processing equipment, etc., can solve the problems of chip blocking, damage, saw wire failure, etc. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] like figure 1 , 3 , 4 shown.

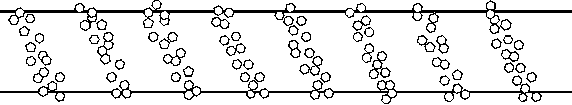

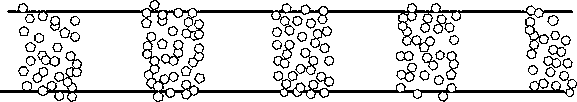

[0028] An electroplated diamond wire saw with a controllable arrangement of abrasives. The material of the steel wire matrix is piano steel wire or spring steel wire. The particle size of diamond abrasive is 10~100μm. Diamond abrasives are spirally arranged on the surface of the steel wire matrix, such as figure 1 shown. figure 1 The preparation method of the electroplated diamond wire saw shown is:

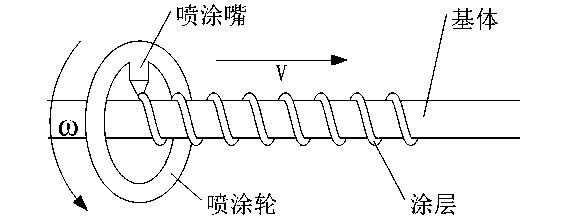

[0029] (1) The selective coating treatment on the surface of the steel wire substrate is completed through a rotating spray wheel, and the paint flows out from the spray nozzle protruding from the spray wheel. The liquid wax or insulating glue flows out from the spray nozzle, solidifies after encountering the surface of the substrate with a lower temperature, and solidifies on the surface of the substrate, such as image 3 As shown, the steel wire substrate moves in a straight line at a uniform speed, and the spraying wheel rotates, a...

Embodiment 2

[0033] like figure 2 , 5 , 6 shown.

[0034] An electroplated diamond wire saw with a controllable arrangement of abrasives. The material of the steel wire matrix is piano steel wire or spring steel wire. The particle size of diamond abrasive is 10~100μm. The diamond abrasives are arranged on the surface of the steel wire matrix in the form of nodules, such as figure 2 shown. figure 2 The preparation method of the electroplated diamond wire saw shown is:

[0035] (1) The selective coating treatment on the surface of the steel wire substrate is completed through a rotating spray wheel, and the paint flows out from the spray nozzle protruding from the spray wheel. The liquid wax or insulating glue flows out from the spray nozzle, solidifies after encountering the surface of the substrate with a lower temperature, and solidifies on the surface of the substrate, such as Figure 5 As shown, the steel wire stationary spraying wheel rotates one revolution to complete the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com