Monofilament metal saw wire

A monofilament type, sawing wire technology, applied in metal sawing equipment, metal processing equipment, sawing machine equipment, etc., can solve the problems of slow and troublesome changes in the outer surface of the sawing wire, and achieve surface quality improvement, long life, and sawing The effect of process stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

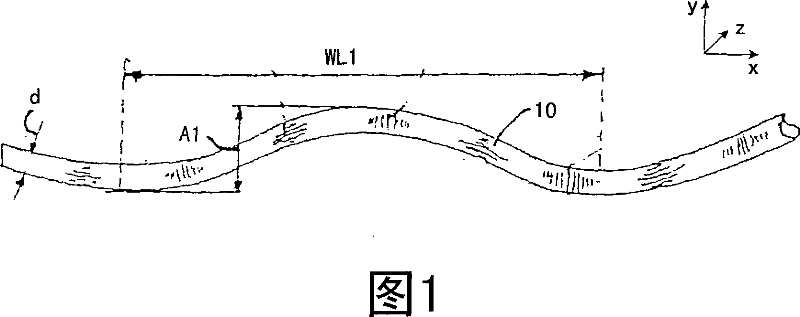

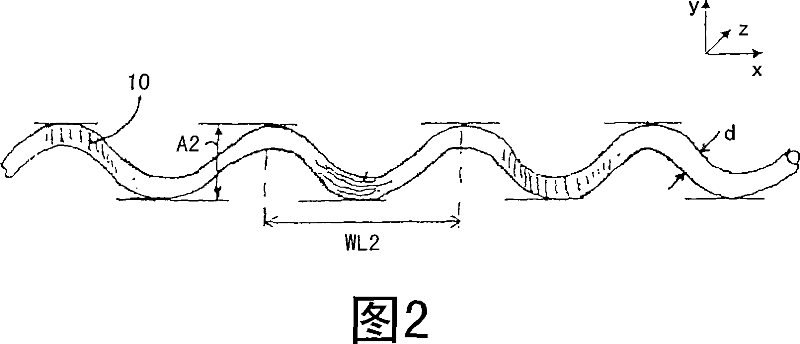

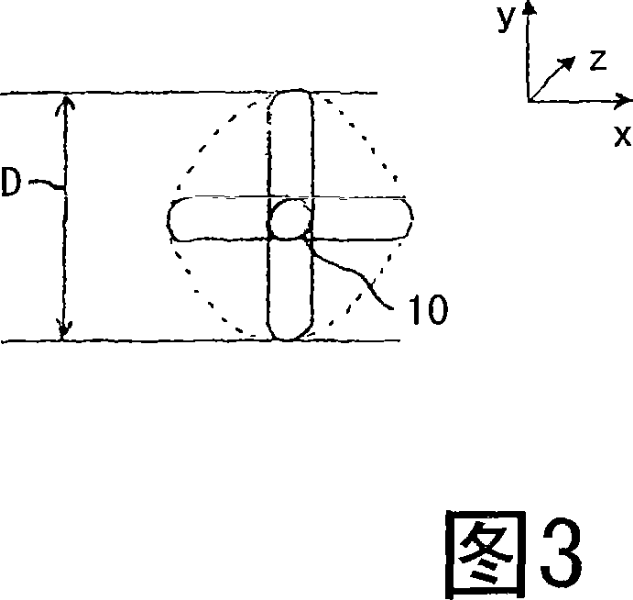

[0033] 1 to 3 illustrate a monofilament type metal sawing wire according to a first embodiment of the present invention. The wire is shown in the x-y plane in FIG. 1 , in the x-z plane in FIG. 2 and in the y-z plane in FIG. 3 . The monofilament type metal sawing wire 10 is provided with a plurality of crimps 12 lying in two different planes. In a first plane, as shown in FIG. 1 , the wire comprises a crimp having a wavelength WL1 and an amplitude A1 . In the second plane, as shown in FIG. 2 , the wire comprises a crimp having a wavelength WL2 and an amplitude A2. Wavelength WL2 is shorter than wavelength WL1, for example, wavelength WL1 may be 5.0 mm, while wavelength WL2 may be about 3.3 mm. The monofilament metal sawing wire 10 itself has a diameter d of 0.25 mm, which remains approximately constant over the entire length of the sawing wire 10 . Preferably, the amplitudes A1 , A2 are 1.10 to 1.30 times the diameter d of the sawing wire 10 . Since the monofilament metal s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com