Cutter abrasion online monitoring method based on wavelet packet analysis and radial basis function (RBF) neural network

A technology of wavelet packet analysis and neural network, applied in the field of online monitoring of tool wear based on wavelet packet analysis and RBF neural network, can solve the problem of low resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

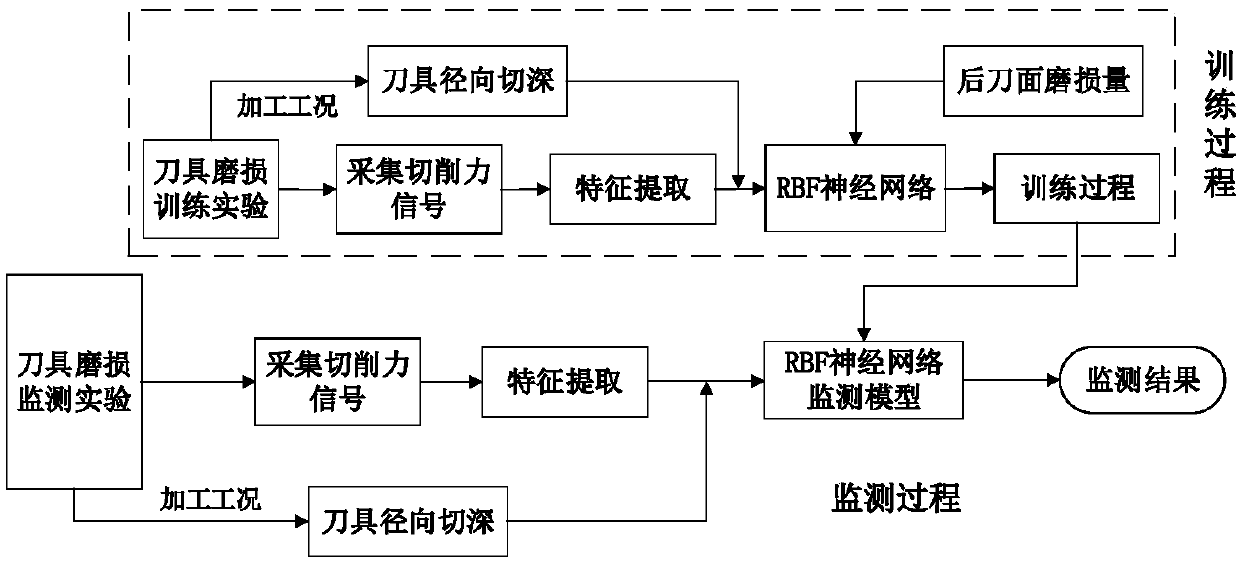

[0032] Refer to attached Figure 1-6 , taking the milling process of titanium alloy, a general aviation material, as an example, the specific implementation of the present invention will be described.

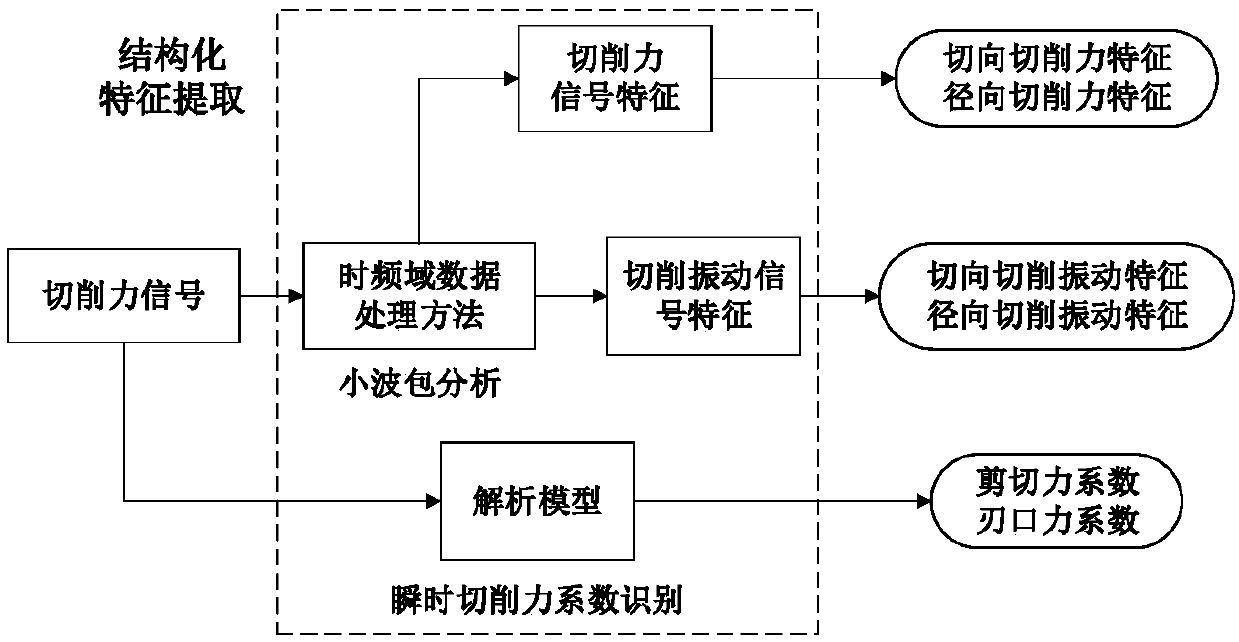

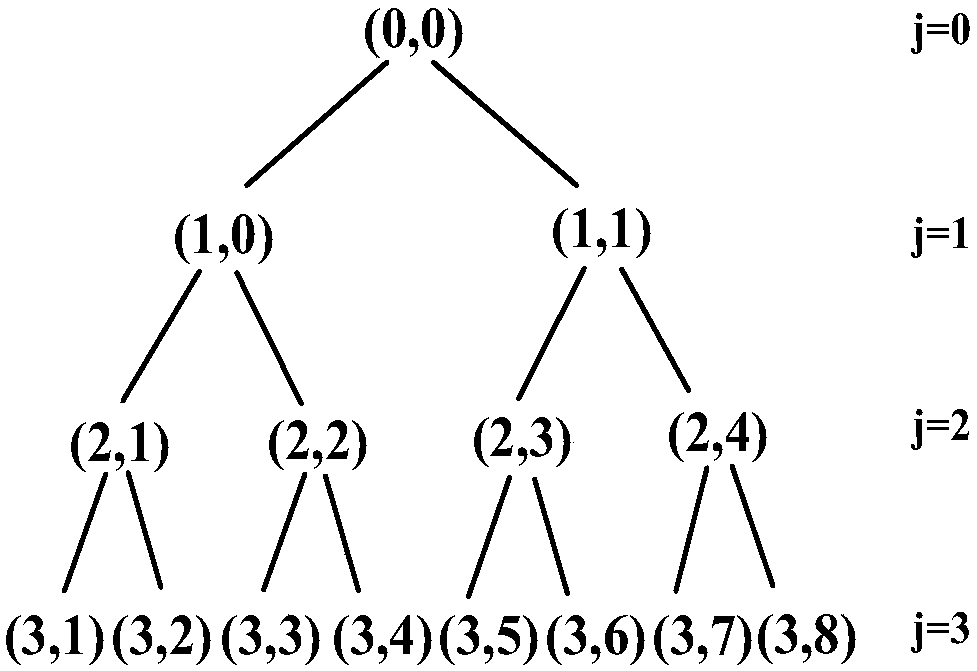

[0033] The present invention proposes an online tool wear monitoring method based on wavelet packet analysis and RBF neural network, with Figure 1-2 Indicates the process flow and feature extraction process of the tool wear on-line monitoring method, which mainly includes 6 steps:

[0034] Step 1: Under a certain working condition, use constant cutting parameters to process the part. The tool mills the side edge with a radial distance of 1mm and an axial depth of 2mm on the titanium alloy workpiece 58 times. The tool changes from initial wear to Blunt wear, measuring the flank wear of the tool after each machining, and extracting 50 sets of tool wear measurement values as the output value of the neural network for training. At the same time, a Kistler 9123C rotary dynamome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com