Method for preparing activated carbon

An activated carbon and carbonization technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of failure to describe the temperature and time of carbonization, failure to detect the ash content of the product, failure to elaborate on the properties of activated carbon, etc., and achieve good removal effect , low ash content and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

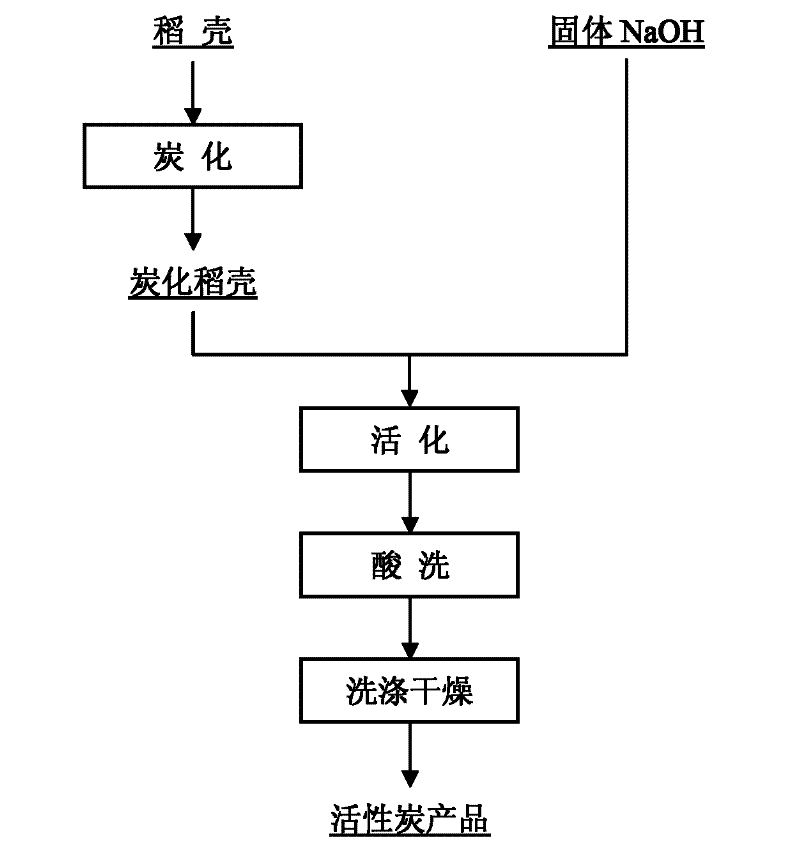

Embodiment 1

[0032] Take appropriate amount of rice husk in N 2 Carbonize at 400°C for 2 hours; mix solid NaOH and carbonized rice husk evenly according to the alkali-carbon ratio of 3:1, first in N 2 Preheat at 400°C for 30min, then activate at 800°C for 2h; pickle with 0.1mol / L HCl; wash with water, filter, dry, and grind to obtain a specific surface area of 2428.05m 2 / g, an activated carbon product with an ash content of 3.76%.

Embodiment 2

[0034] Take an appropriate amount of rice husk and carbonize at 700°C for 2 hours; mix the reactants according to the alkali-carbon ratio of 3:1, preheat at 400°C for 30 minutes, activate at 800°C for 2 hours; pickle with 0.1mol / L HCl; wash with water, filter, dry, and grind to obtain The specific surface area is 1993.98m 2 / g, the product with an ash content of 3.23%.

Embodiment 3

[0036] Take an appropriate amount of rice husk and carbonize at 600°C for 2 hours; mix the reactants according to the alkali-carbon ratio of 3:1, preheat at 400°C for 30 minutes, activate at 800°C for 1 hour; pickle with 0.1mol / L HCl; wash with water, filter, dry, and grind to obtain The specific surface area is 2186.36m2 / g, the product with an ash content of 4.89%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com