Microbial organic fertilizer and manufacture method of microbial organic fertilizer

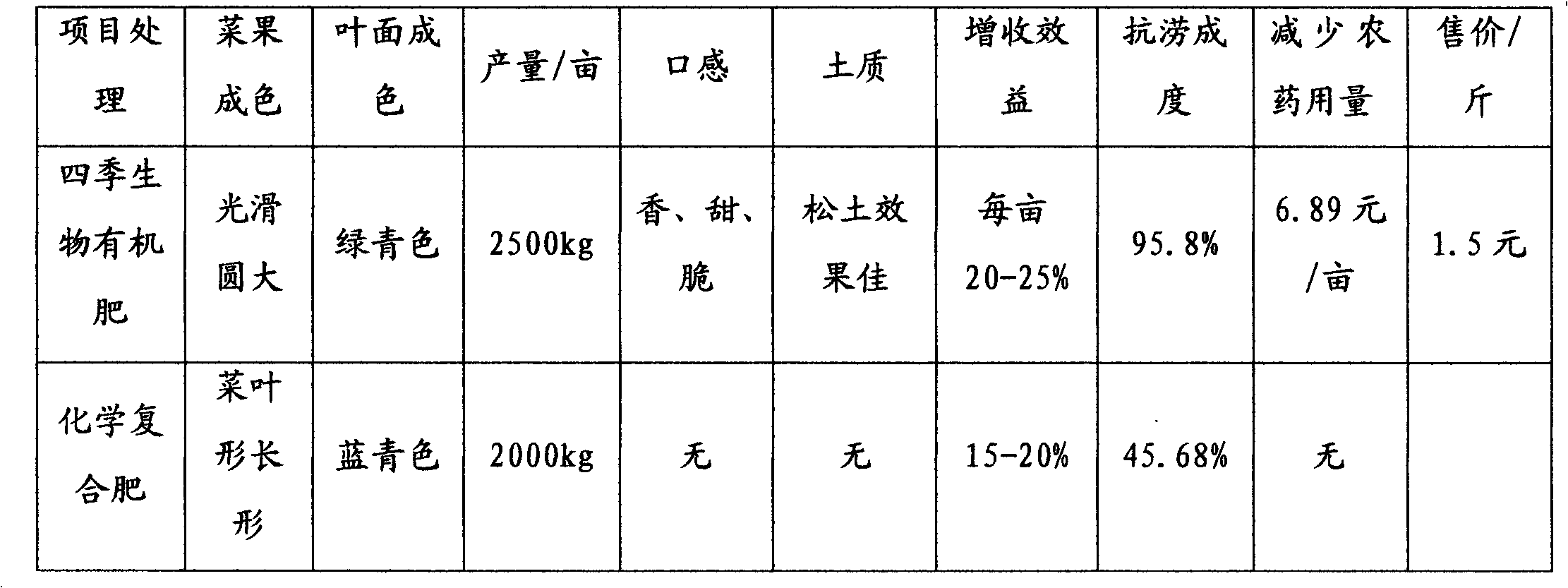

A technology of bio-organic fertilizer and production method, which is applied to the preparation of organic fertilizer, bio-organic part treatment, organic fertilizer, etc., can solve the problems of non-standard decomposing and fermentation, poor soil improvement, and little actual use, so as to reduce farmers' expenditure, Realize the effects of ecological agriculture, environmental protection and pollution elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

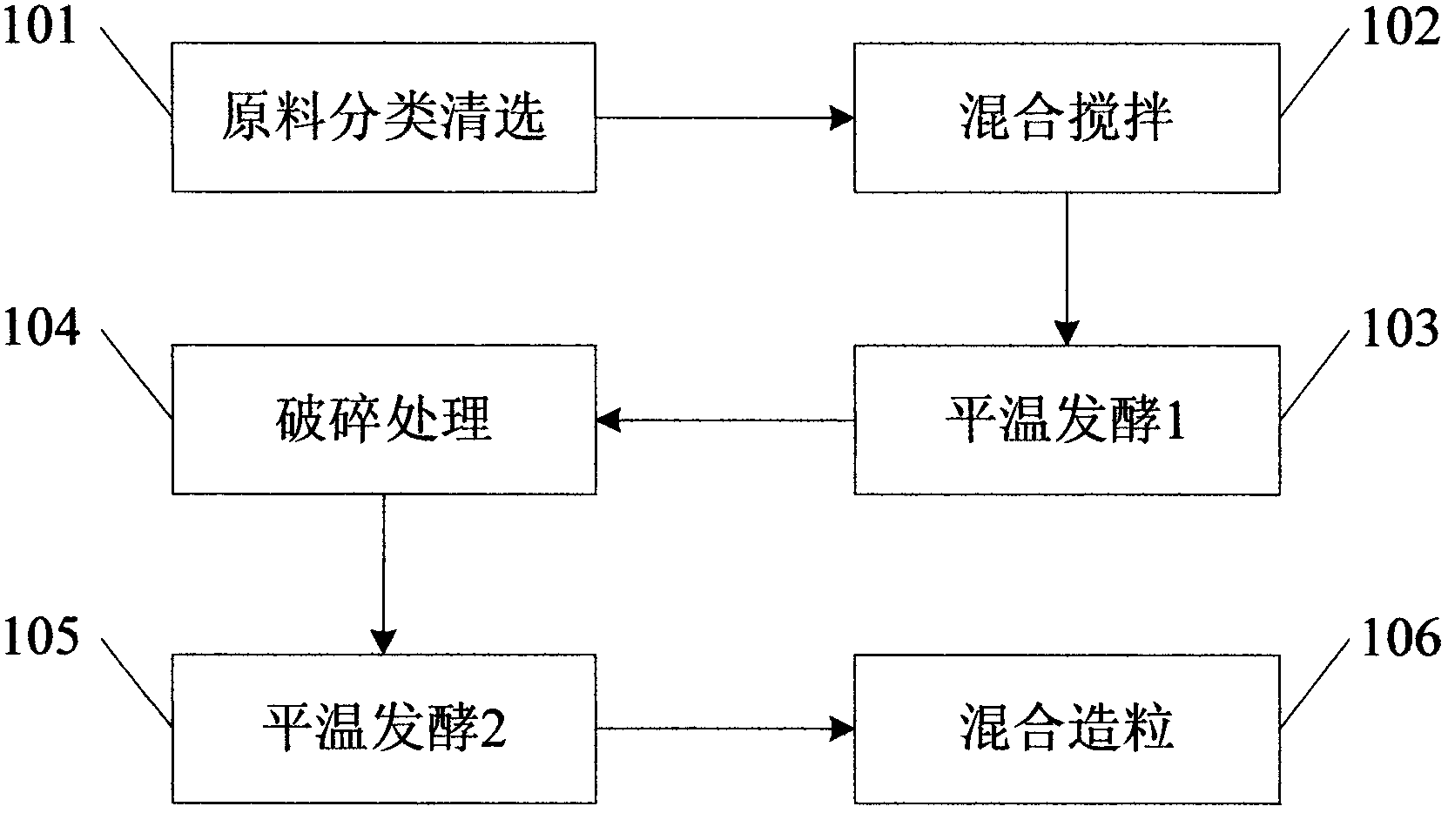

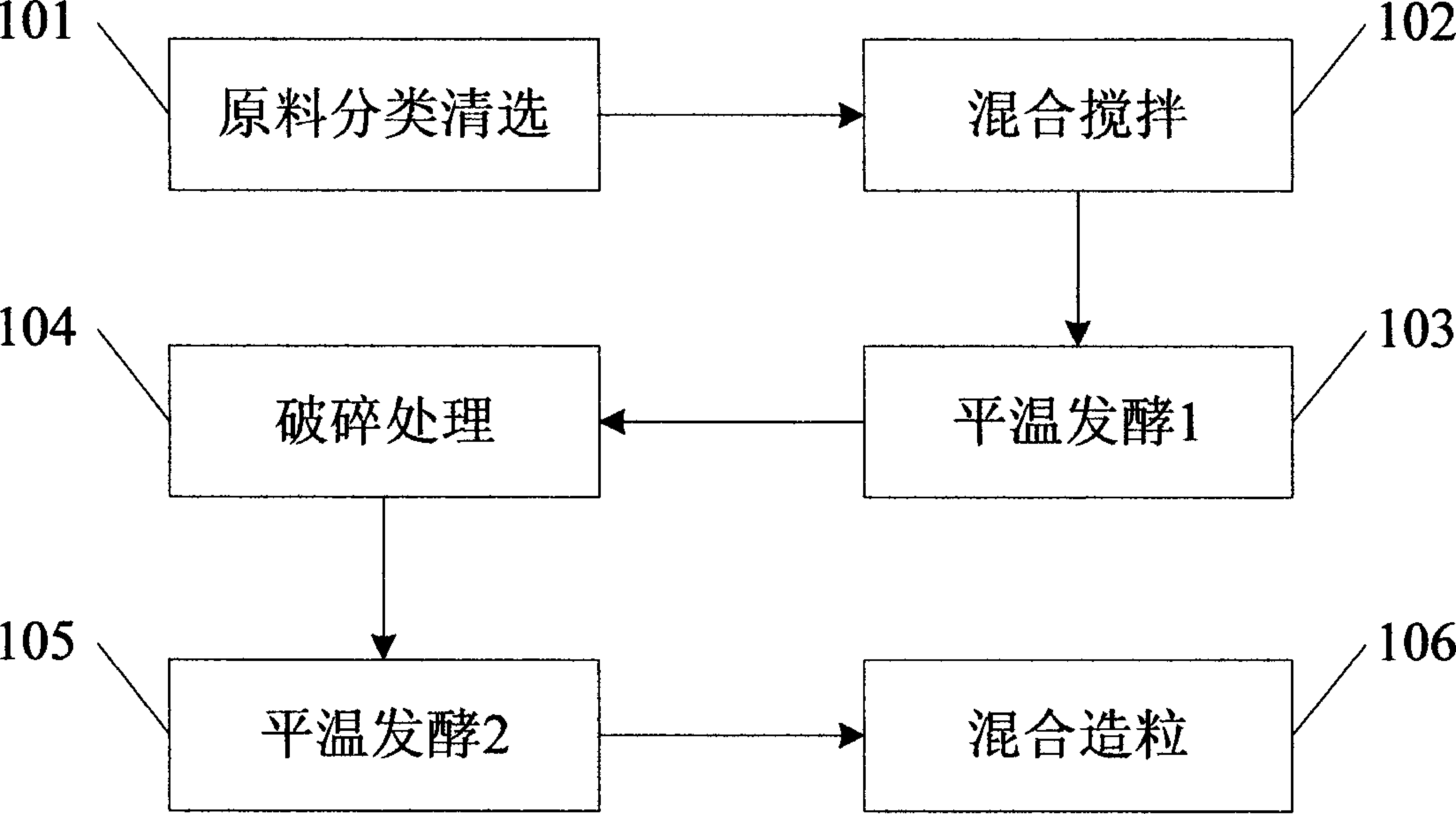

Method used

Image

Examples

Embodiment 1

[0049]The raw materials after classification and cleaning are by raw material mass percentage livestock (cattle, sheep, horse, pig) manure 17.8%, poultry (chicken, duck, goose) manure 20%, organic matter (weathered coal) 19.89375%, house refuse 5%, 5% dry cake, 5% rice husk, straw and weeds, 2% crop stalks and 5% pyrotechnic ash are mixed, add 40% water and stir evenly with a mixer; add 0.0001% compound bacterial agent 1 according to the mass percentage of raw materials Perform flat temperature fermentation 1 treatment, keep the fermentation temperature at 50-70°C, and ferment for 8-10 days; use a crusher to crush the product after flat temperature fermentation 1; add 0.15615 % Composite bacterial agent 2 is treated with flat temperature fermentation 2, the fermentation temperature is kept at 20-45°C, and fermented for 4-5 days; the fermentation is completed when the temperature reaches below 25%, and the moisture is below 20%; the product after flat temperature fermentation 2 ...

Embodiment 2

[0054] The raw materials after classification and cleaning are 25% by mass percentage of livestock (cattle, sheep, horse, pig) excrement, 20% of poultry (chicken, duck, goose) excrement, 20% of organic matter (brown coal), 5% of household garbage, dry 9.7375% cake, 5% chaff, straw and weeds and 2% crop stalks are mixed, 40% water is added and stirred evenly with a mixer; Keep the fermentation temperature at 50-70°C and ferment for 8-10 days; use a crusher to crush the product after flat temperature fermentation 1; add 0.1624% composite bacterial agent 2 to the crushed product according to the mass percentage of raw materials Warm fermentation 2 treatment, the fermentation temperature is maintained at 20-45 ° C, and fermentation is carried out for 4-5 days; the temperature reaches below 25%, and the fermentation is completed when the moisture is below 20%; to the product after the flat temperature fermentation 2 treatment, add 5 % nitrogen fertilizer, 5% phosphate fertilizer, 3...

Embodiment 3

[0059] The raw materials after classification and cleaning are by raw material mass percentage livestock (cattle, sheep, horse, pig) excrement 27.7%, poultry (chicken, duck, goose) excrement 5%, organic matter (weathered coal) 20%, withered cake 5%, 5% of leaves, 5% of chaff, rice straw and weeds, 2% of crop straw and 5% of fire ash are mixed, and 40% of water is added and stirred evenly with a mixer; 0.0001% of compound bacterial agent 1 is added according to the mass percentage of raw materials Flat-temperature fermentation 1 treatment, the fermentation temperature is kept at 50-70°C, and fermentation is carried out for 8-10 days; the product after flat-temperature fermentation 1 is crushed with a crusher; the crushed product is added 0.15615% according to the mass percentage of raw materials Composite bacterial agent 2 is treated with flat temperature fermentation 2, the fermentation temperature is kept at 20-45°C, and fermented for 4-5 days; the fermentation is completed wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com