Method for extracting iridoid active site and monomer from eucommia bark

A technology for iridoids and active parts, which is applied in the field of extracting iridoid active parts and monomers from Eucommia ulmoides, can solve the problems of rough processing technology, low technological content, cumbersome operation, etc., and improve product purity and production efficiency. Efficiency, saving organic reagents, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

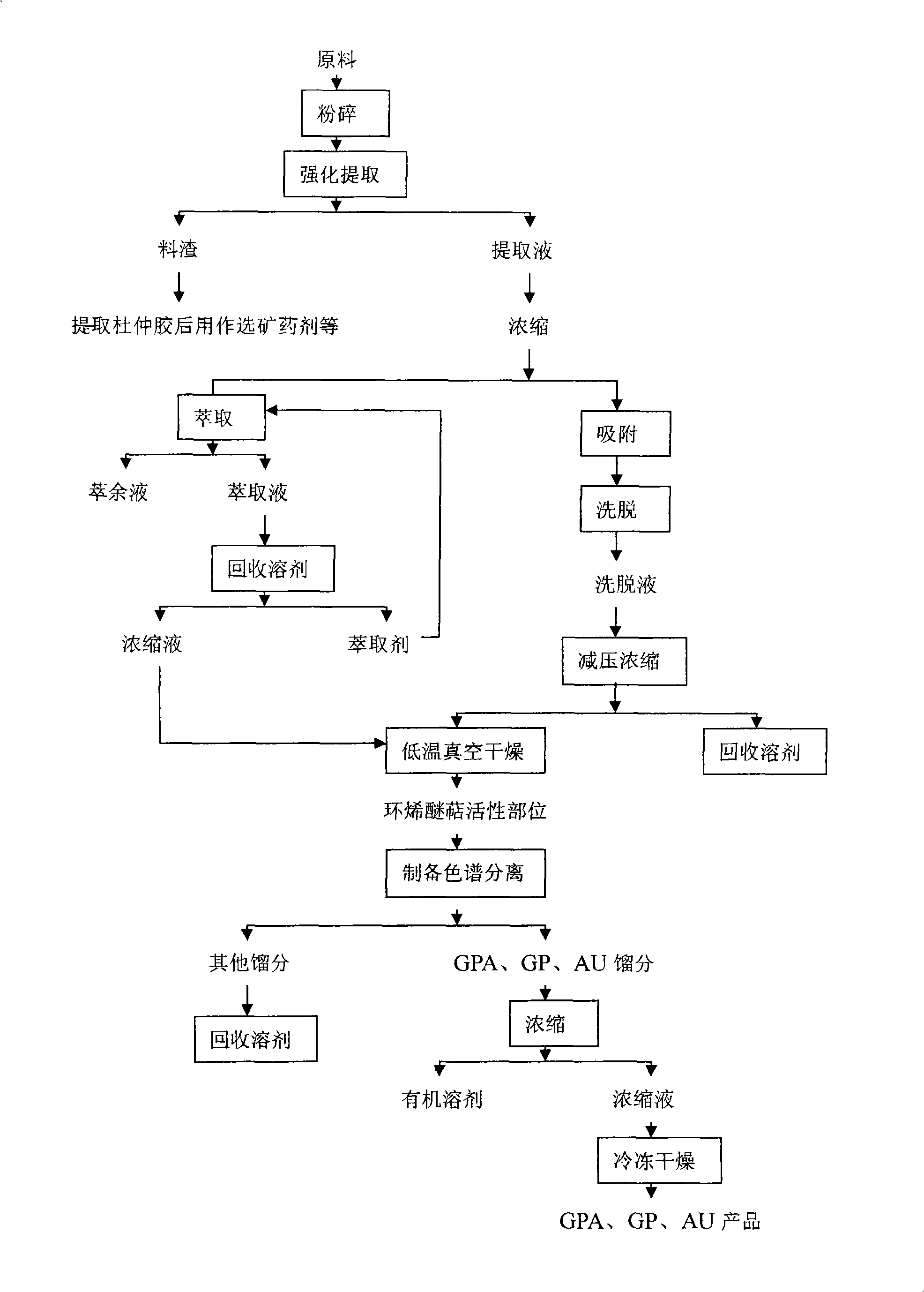

Method used

Image

Examples

Embodiment 1

[0023] (1) The ulmoides bark is dried, crushed, and sieved, preferably the fresh bark of ulmoides ulmoides. Weigh 20 kg of the treated bark of Eucommia, adopt conventional extraction, add 70% ethanol-water solution as the extractant at a liquid-solid ratio of 15 times, extract at 60°C for 2 hours, and repeat 3 times. Filter the extract, concentrate, and adjust the pH to 1.5-4.5 with hydrochloric acid;

[0024] (2) Use n-butanol to extract, collect the extract, cool the concentrated solution to -10~-20°C, then place it in a freeze dryer and cool it to -45~-65°C, vacuum degree ≤ 20Pa, time 24~48 hours Low-temperature vacuum drying to obtain 480.5 grams of iridoid active parts, with a total iridoid compound content of 53.20%;

[0025] (3) 2.5000 grams of iridoid active sites are dissolved, separated by preparative high-performance liquid chromatography, and the used column packing is C 18 or C 8 , the particle size is 5-50 μm, and the mobile phase is ethanol-water system for g...

Embodiment 2

[0029] (1) Eucommia leaves are dried, crushed, and sieved, and it is better to pick Eucommia leaves in November. Weigh 500 grams of treated Eucommia leaves and use ultrasonic extraction, add 50% ethanol at a liquid-solid ratio of 18 times, ultrasonically extract for 30 minutes at a temperature of 60° C. and a frequency of 80 KHz, and repeat the treatment 3 times. Filter and concentrate the extract;

[0030] (2) Adsorption and elution with a weakly polar adsorbent, concentration of the eluent, and low-temperature vacuum drying using the method of Example 1, to obtain the iridoid active site (content: 51.21%);

[0031] (3) Dissolving 2.5000 g of the iridoid active site, using HPLC preparative chromatography to separate (the method is the same as in Example 1), and collecting GPA, GP, and AU fractions respectively;

[0032] (4) Concentrate and freeze-dry the above fractions respectively to obtain powdered GPA461 mg, GP51 mg and AU410 mg. High-performance liquid chromatography a...

Embodiment 3

[0034](1) Eucommia seeds are dried, crushed and sieved. The processed eucommia seeds are weighed, and the linolenic acid is firstly extracted with supercritical carbon dioxide to obtain the seed meal. Weigh 200 grams of eucommia seed meal, extract by microwave, add 25% ethanol to microwave for 35 seconds at a liquid-solid ratio of 40 times, and repeat the treatment 4 times. Filter and concentrate the extract, and adjust the pH to 1.5-4.5 with hydrochloric acid;

[0035] (2) extracted with ethyl acetate and n-butanol, collected the extract, and dried in vacuum at low temperature using the method of Example 1 to obtain the iridoid active site (content: 51.11%);

[0036] (3) 2.5000 grams of iridoid active sites were dissolved, and the method of Example 1 was used for separation by high-performance liquid chromatography, and GPA, GP, and AU fractions were collected respectively;

[0037] (4) The above fractions are concentrated and freeze-dried respectively to obtain 55 mg of po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com