Coal injection system of blast furnace

A technology of blast furnace coal injection and tank injection, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as lagging of injection rates, delays, and damage to furnace conditions, so as to prevent lags and large fluctuations, and enhance self-efficacy. Adaptability, the effect of avoiding large fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

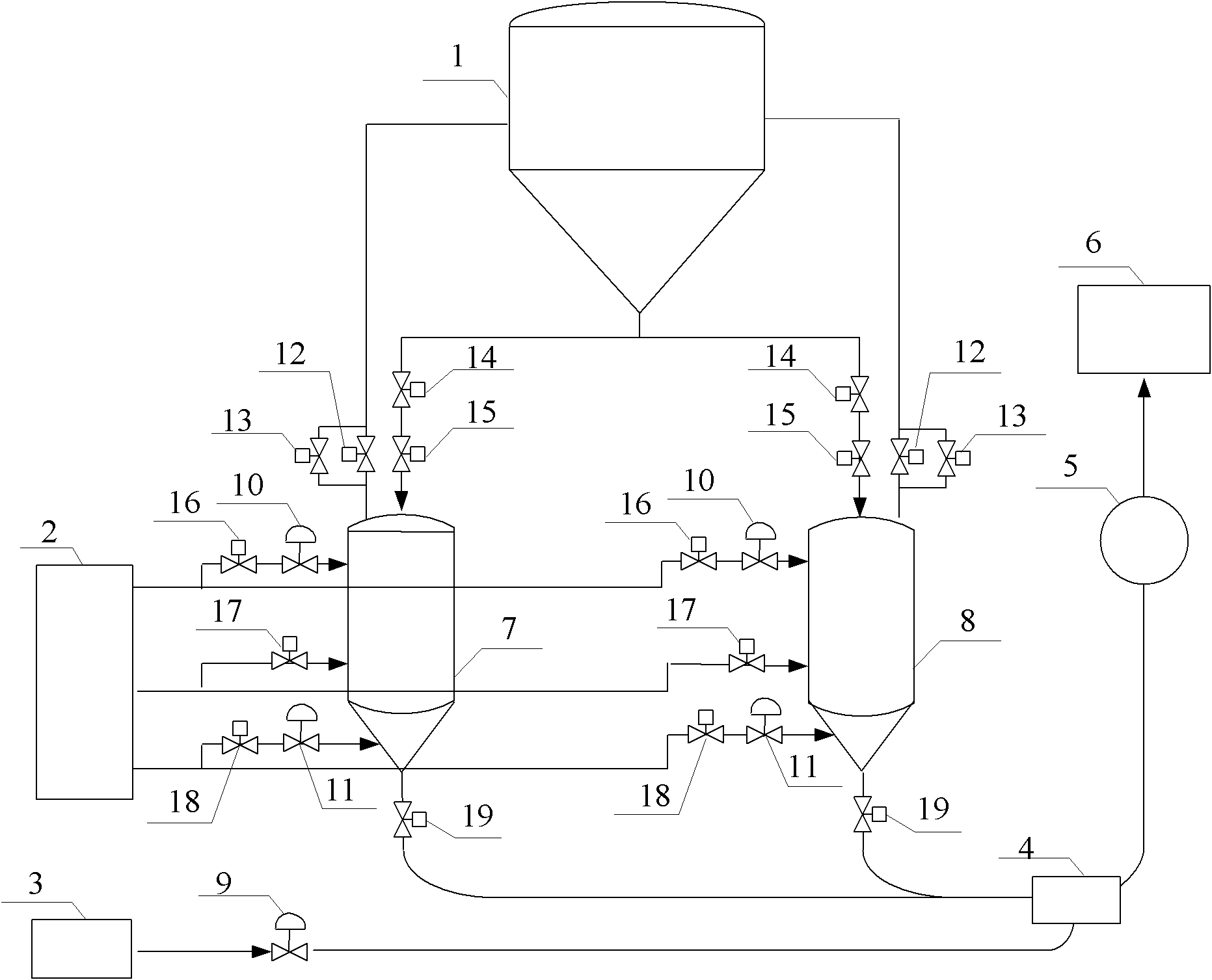

[0021] The blast furnace coal injection injection system provided by the present invention can realize the control of the blast furnace coal injection injection rate, and the system includes a nitrogen pressure regulating station 2, an air compressor station 3, a mixer 4, a distributor 5, and multiple injection tanks , Shut-off valve and regulating valve.

[0022] The structure of the blast furnace coal injection injection system will be described below by taking the two-tank parallel injection mode as an example.

[0023] Such as figure 1 As shown, the blast furnace coal injection injection system is provided with a first injection tank 7 and a second injection tank 8, which are respectively connected to the pulverized coal bin 1 through pipelines, a charging shut-off valve 14, and a blanking shut-off valve 15. Fill the blowing tank, and at the same time connect with the pulverized coal bin 1 through the pipeline, the small release shut-off valve 12, and the large release sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com