Patents

Literature

49results about How to "Reduce axle load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

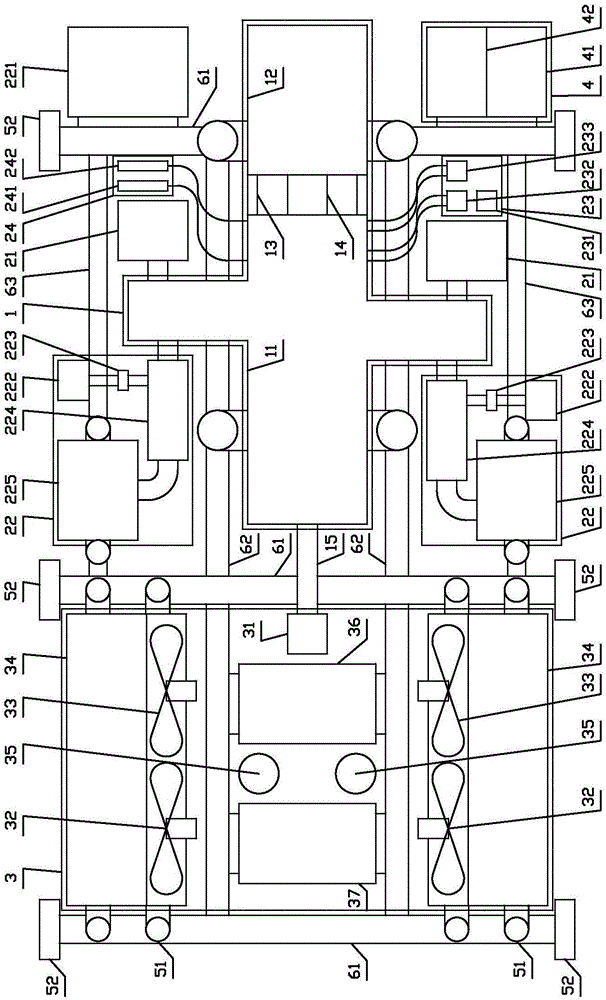

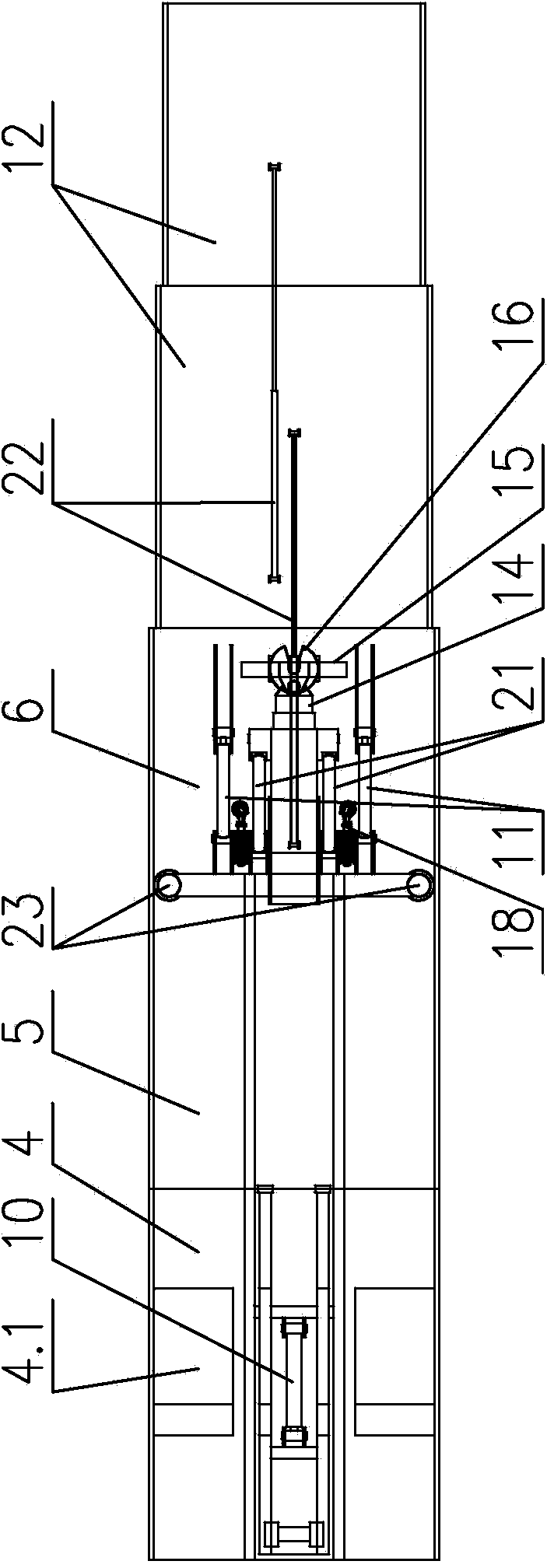

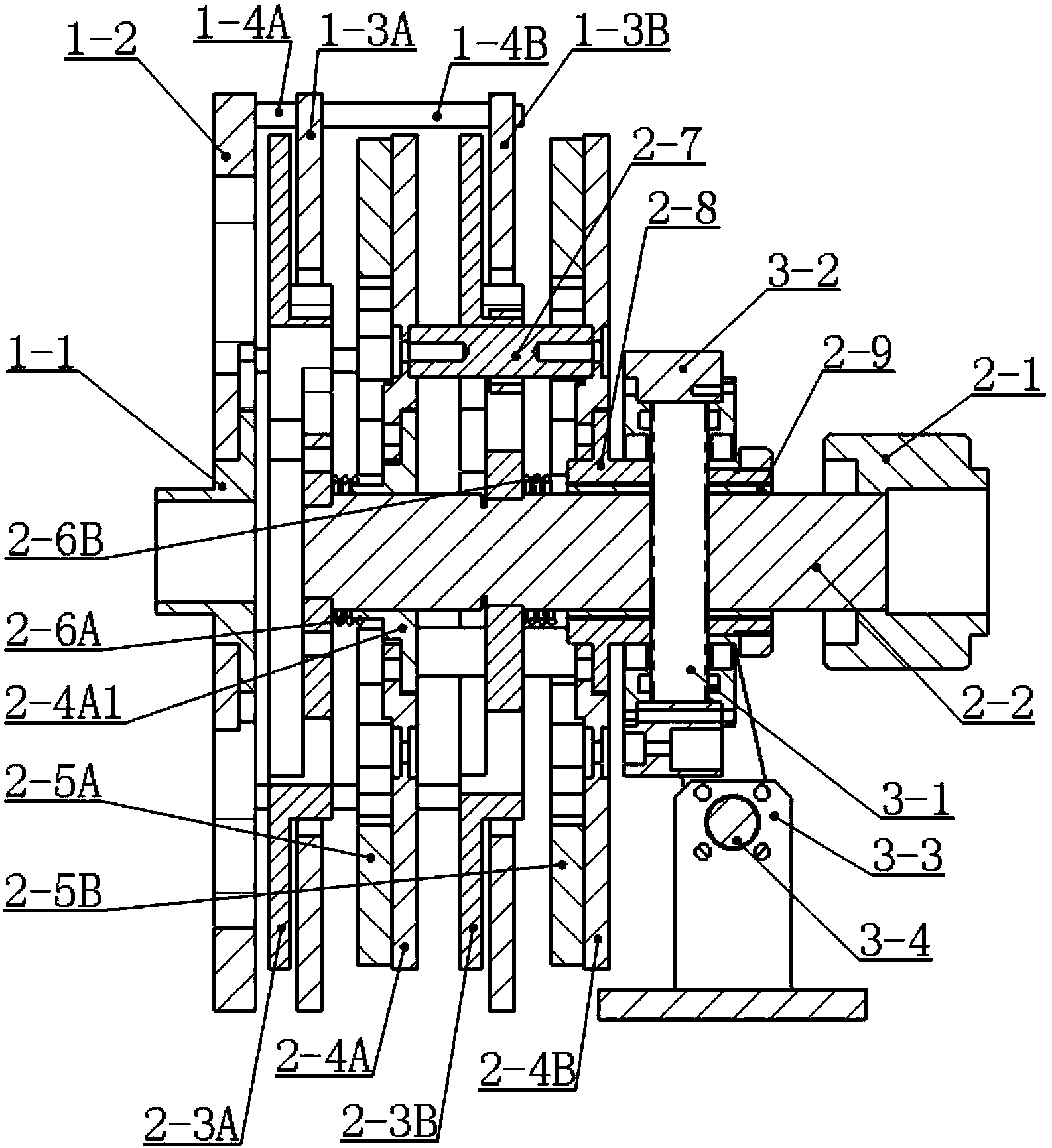

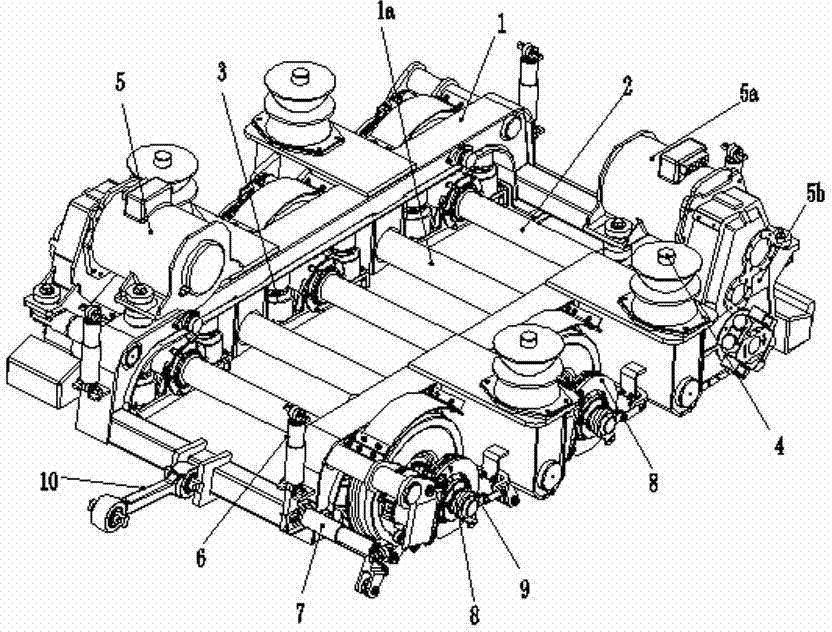

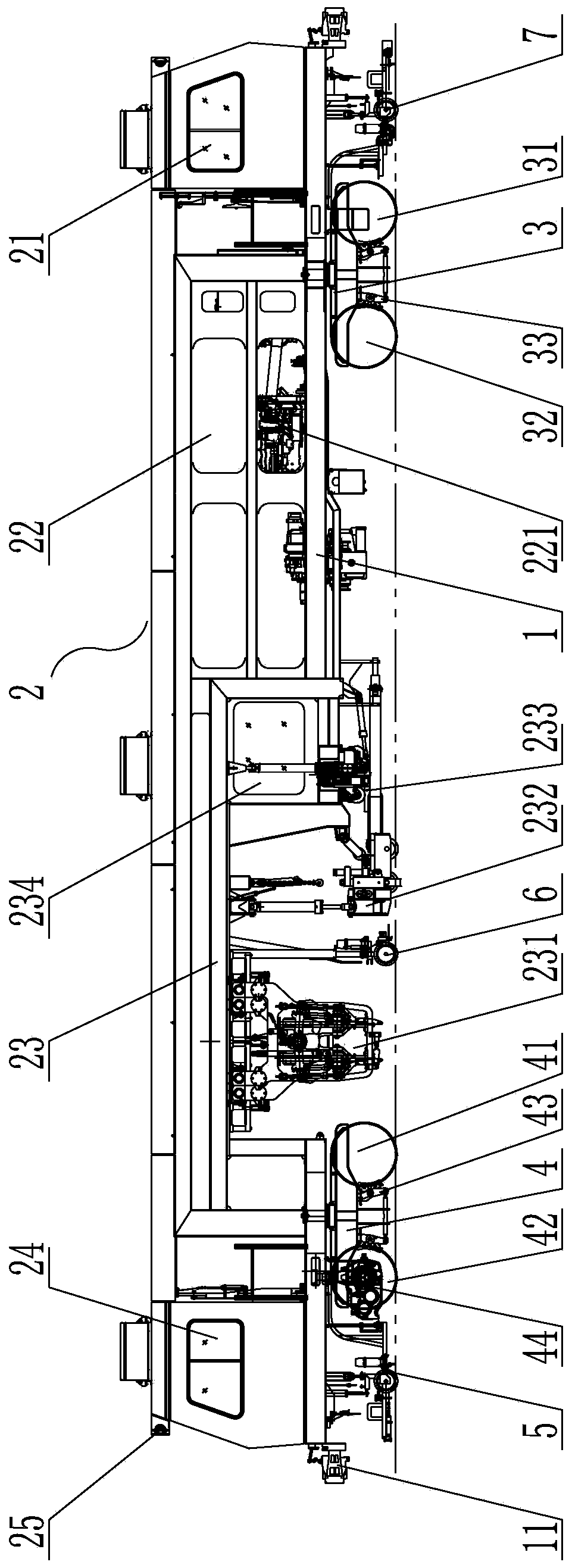

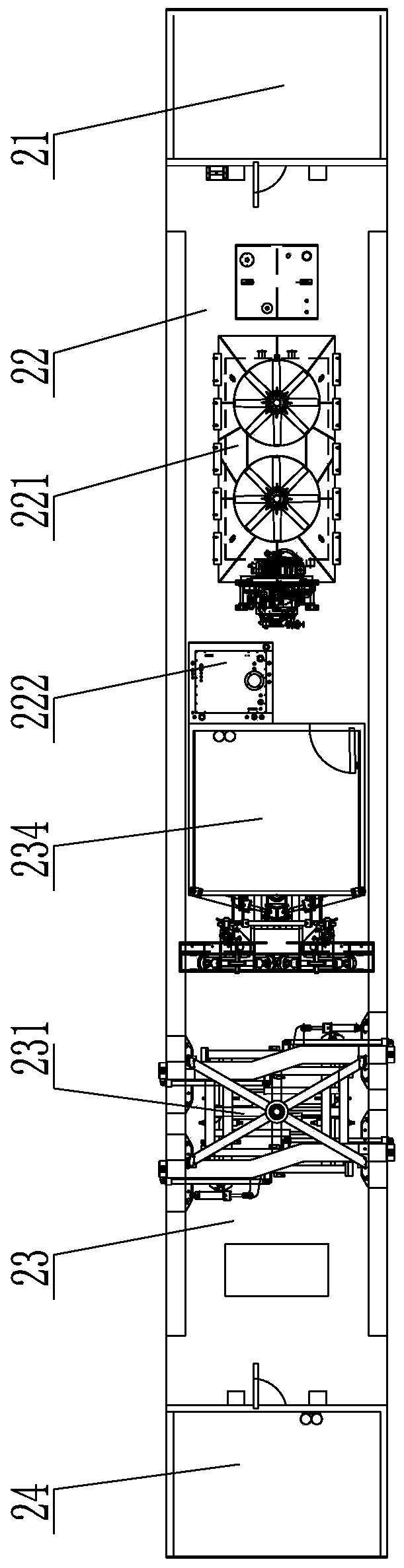

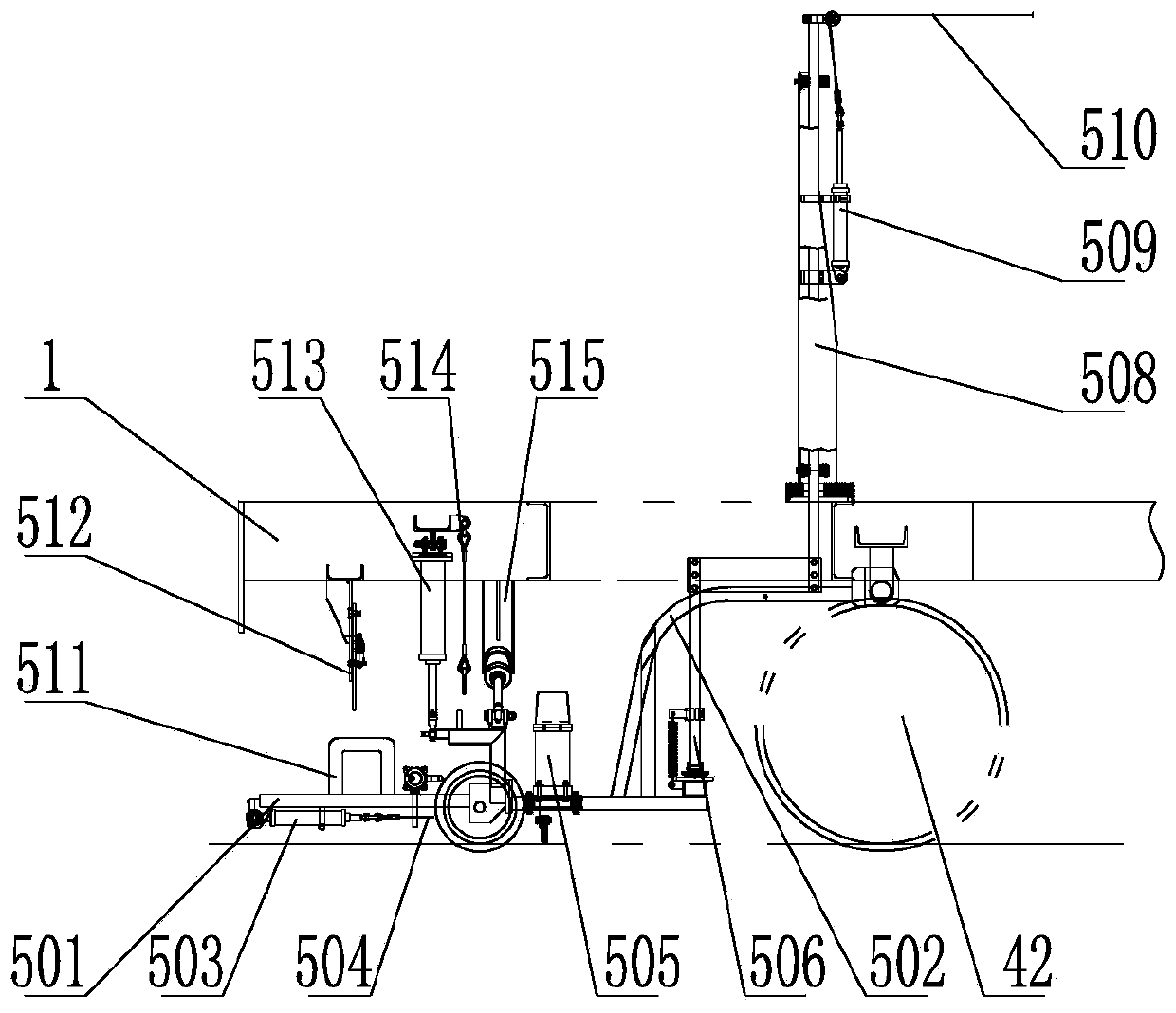

Bottom-arranged power integrated system for high-speed internal combustion motor train unit

ActiveCN106347378AReduce axle loadMeet the needs of high-speed passenger transportIC engine locomotivesIC reciprocating piston engine transmissionExpansion tankAir filter

The invention discloses a bottom-arranged power integrated system for a high-speed internal combustion motor train unit. The bottom-arranged power integrated system for the high-speed internal combustion motor train unit comprises a diesel generating set, a diesel auxiliary system, a cooling system, an electronic control system and a mounting frame, wherein the diesel generating set comprises a diesel and a generator; the generator and the diesel are fixed through a connecting flange; the diesel auxiliary system comprises an inlet air filter, an exhaust SCR aftertreatment system, a fuel system and an engine oil system which are arranged on two sides of the diesel generating set; the cooling system comprises a fixed hydraulic pump, a cooling device, an expansion water tank and a fixed hydraulic tank; the diesel generating set and the cooling device are fixed on the mounting frame through elastic rubber dampers; and the mounting frame is hung below a floor of a vehicle through an elastic rubber damper. While axle weight of the bottom-arranged power integrated system for the high-speed internal combustion motor train unit is reduced, passenger carrying space on the vehicle can be utilized to a maximum extent,, and therefore, requirements of high speed passenger transportation are met.

Owner:CRRC DALIAN INST CO LTD

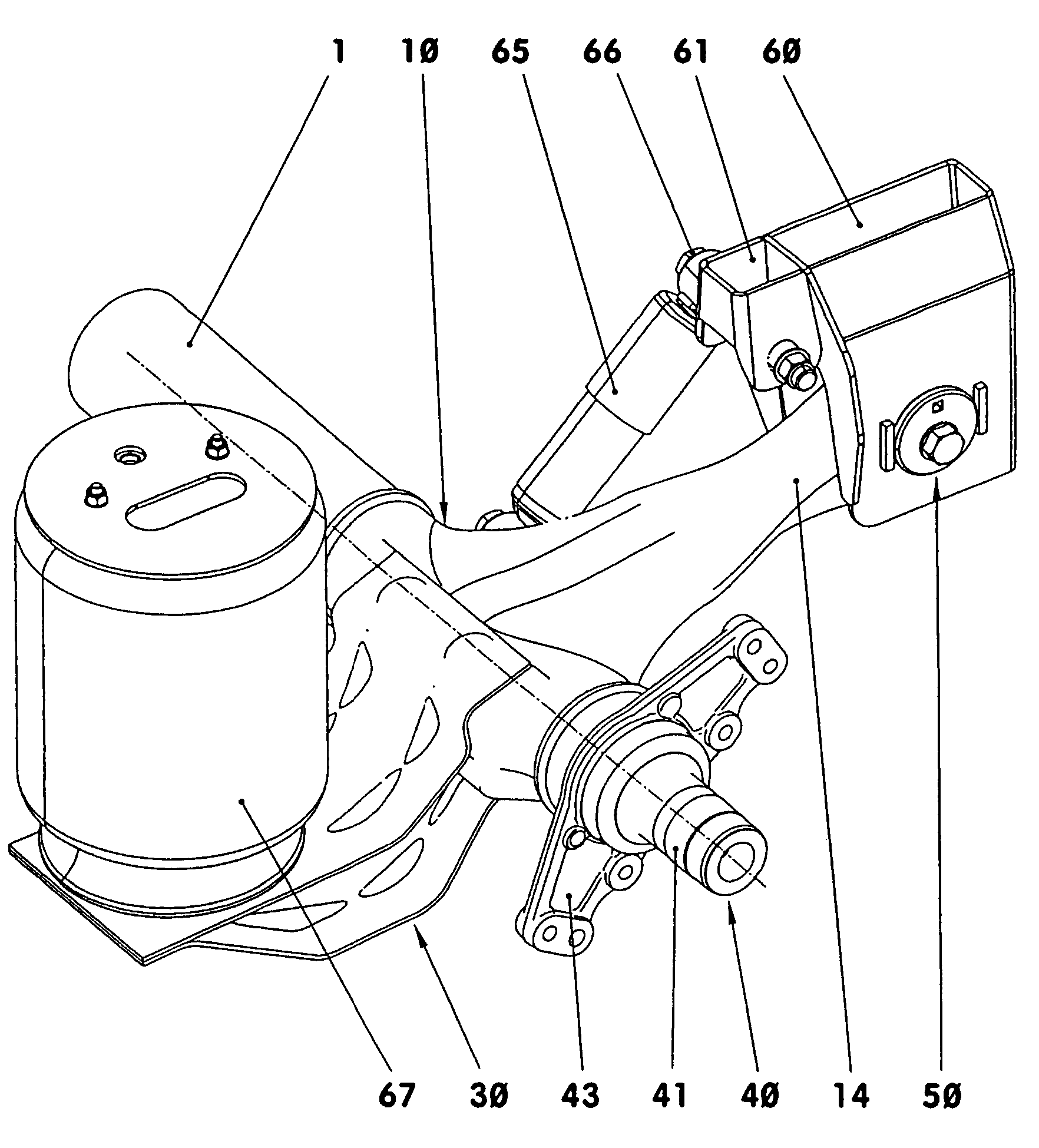

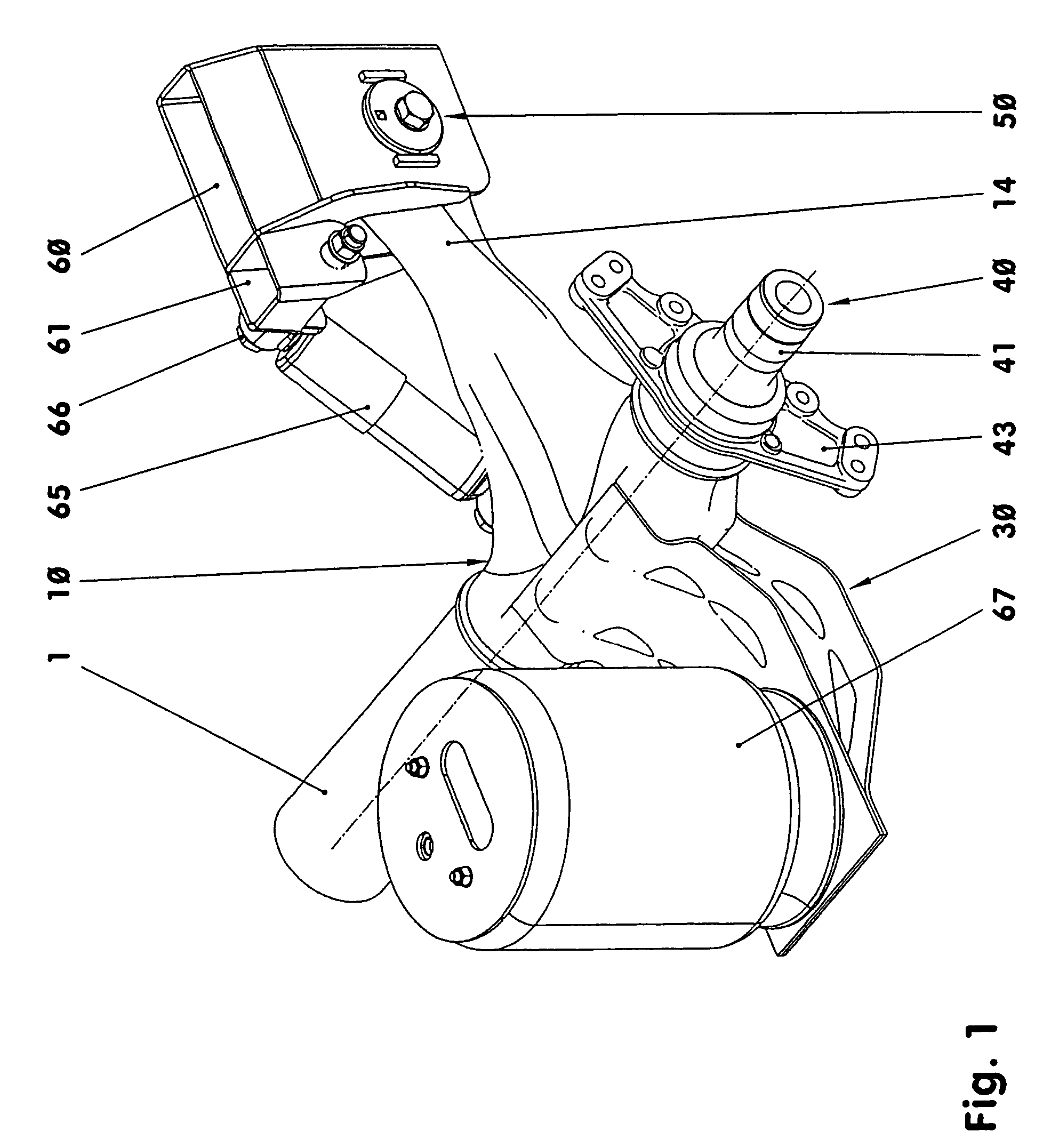

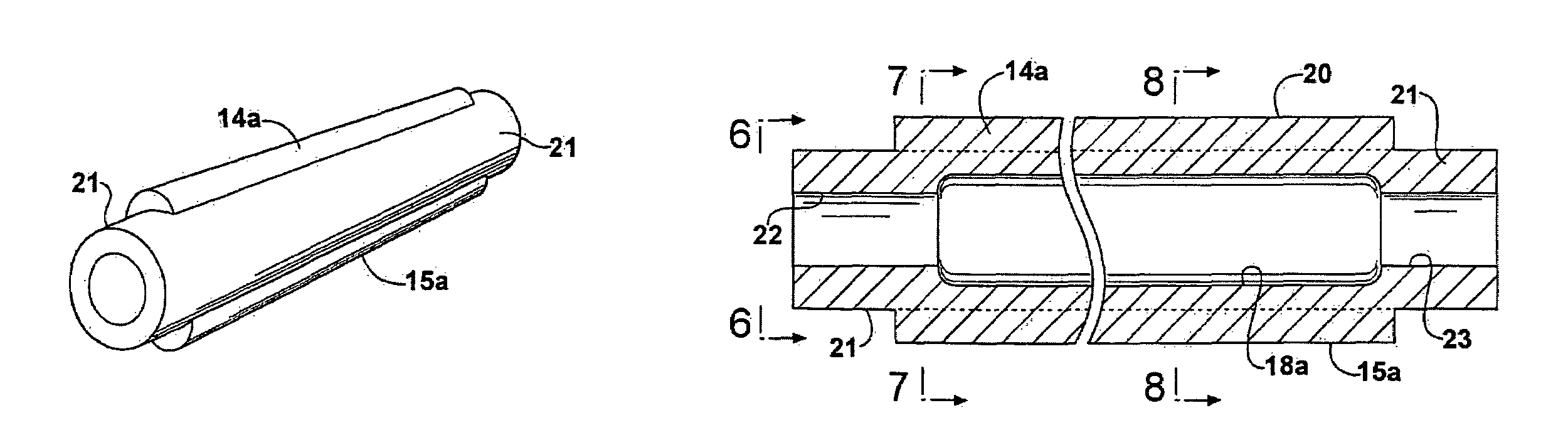

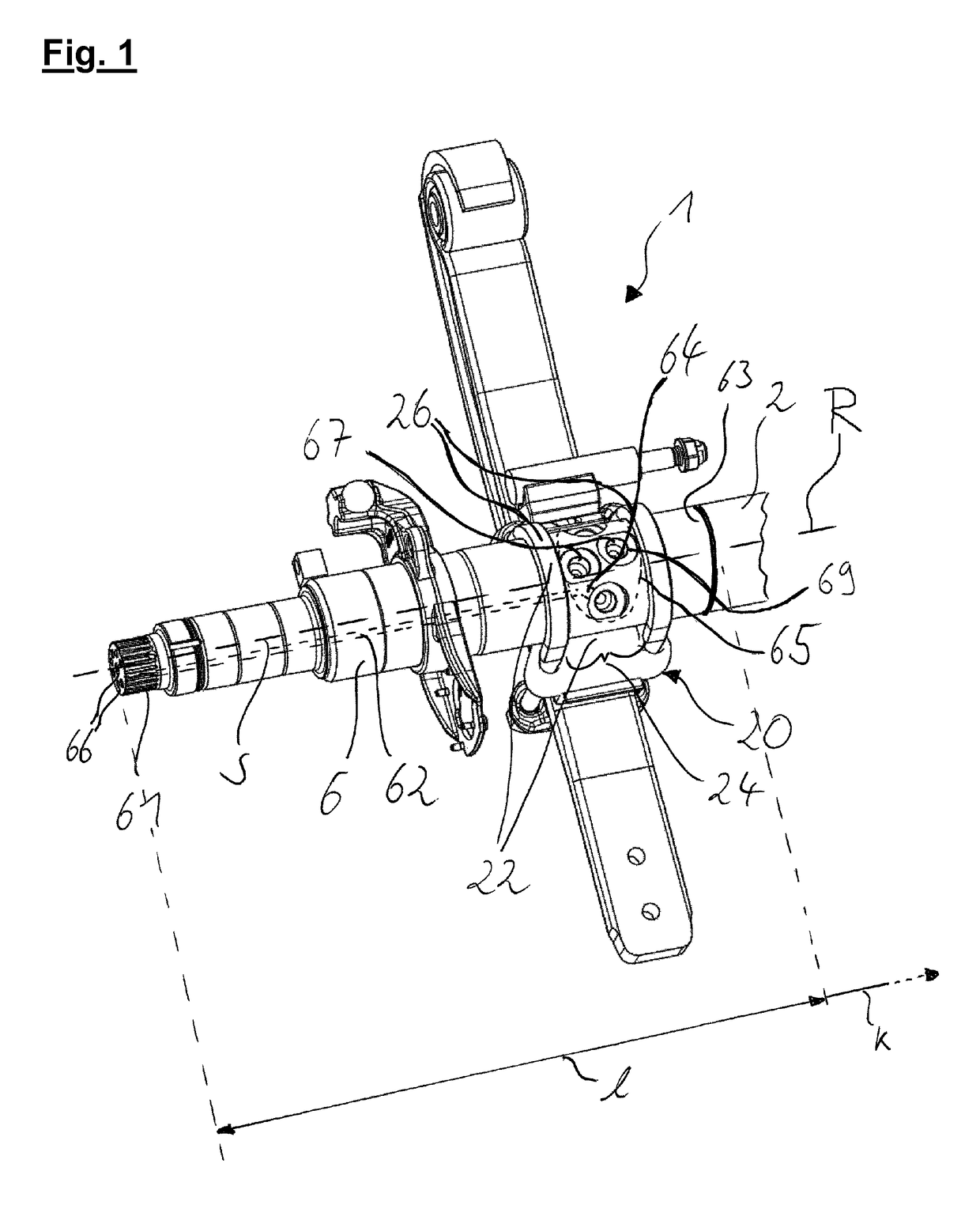

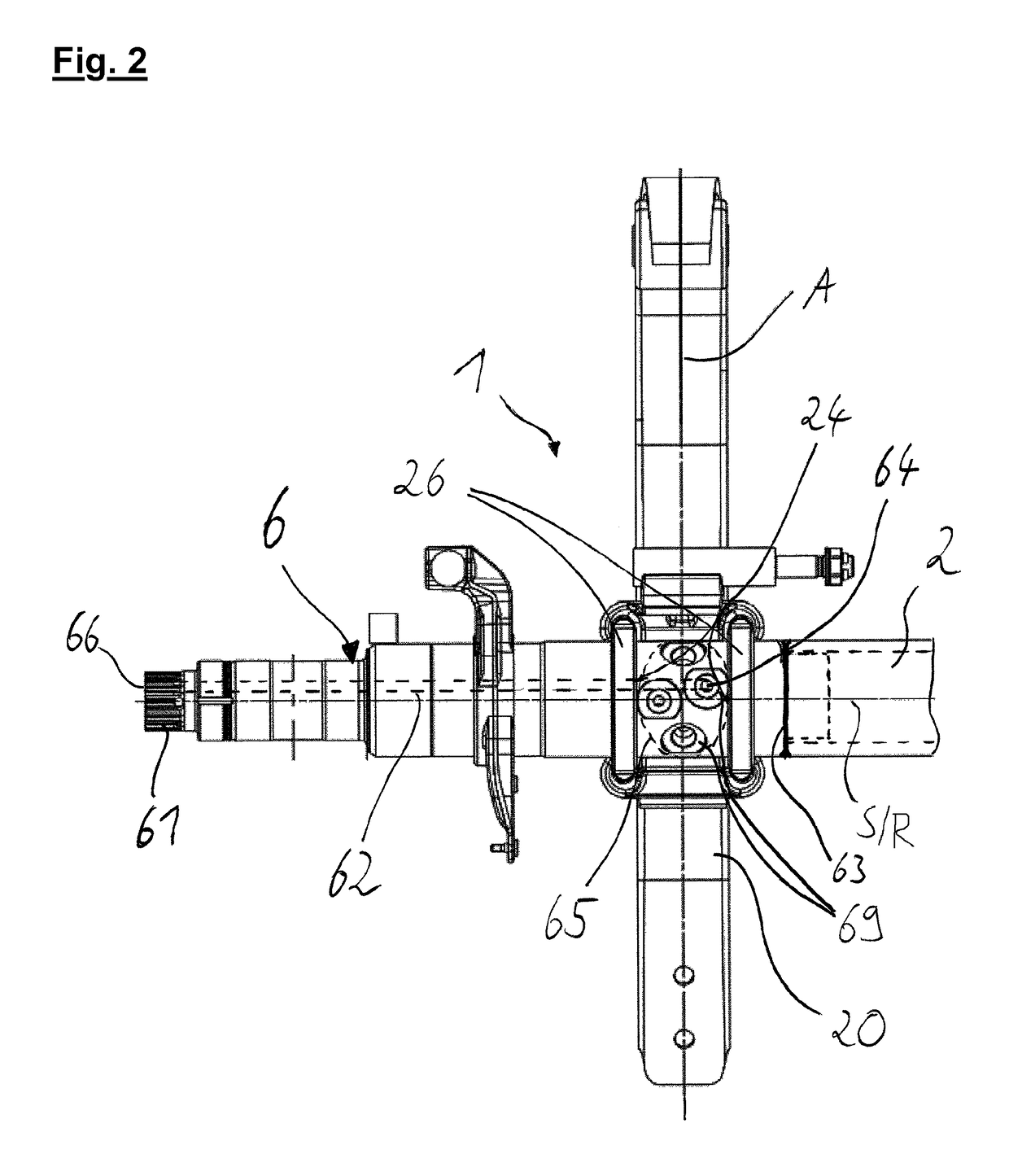

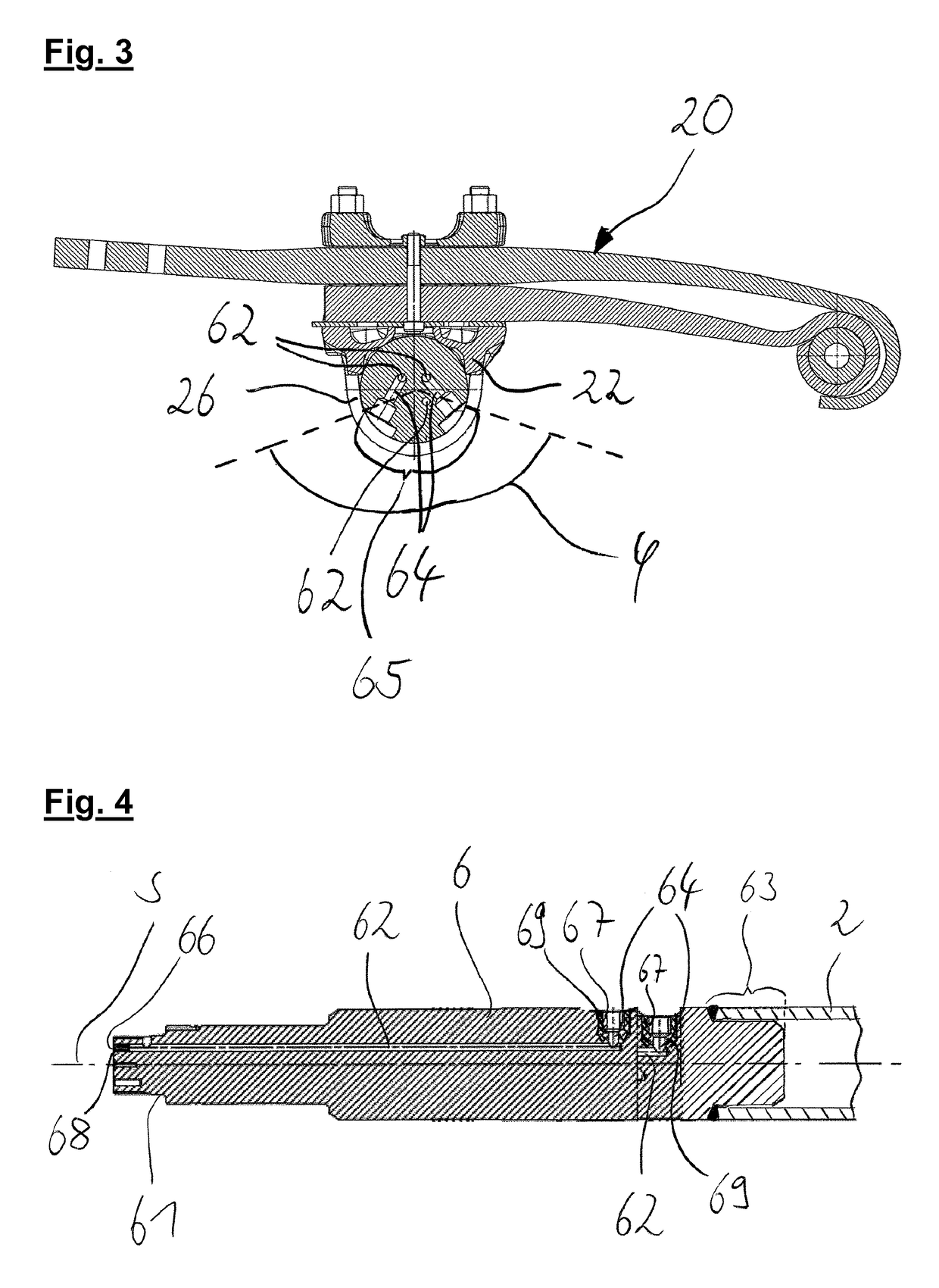

Rigid vehicle axle with integral trailing arms

ActiveUS7370872B2Reduce axle loadPrevent materialInterconnection systemsResilient suspensionsTrailing armAutomotive engineering

In a rigid vehicle axle comprising an axle beam with axle journals forming wheel carriers arranged at the ends thereof, and at least two trailing arms rigidly fixed to the axle beam, each half of the rigid vehicle axle comprises an axle beam section, a trailing arm section and a wheel head section arranged adjacent one after another and the ends of the axle tube sections overlap with the adjoining ends of the trailing arm sections and their end faces are congruent with the respectively adjoining end faces of the wheel head sections, at least in some areas, and the adjoining sections are welded together.

Owner:JOST WERKE

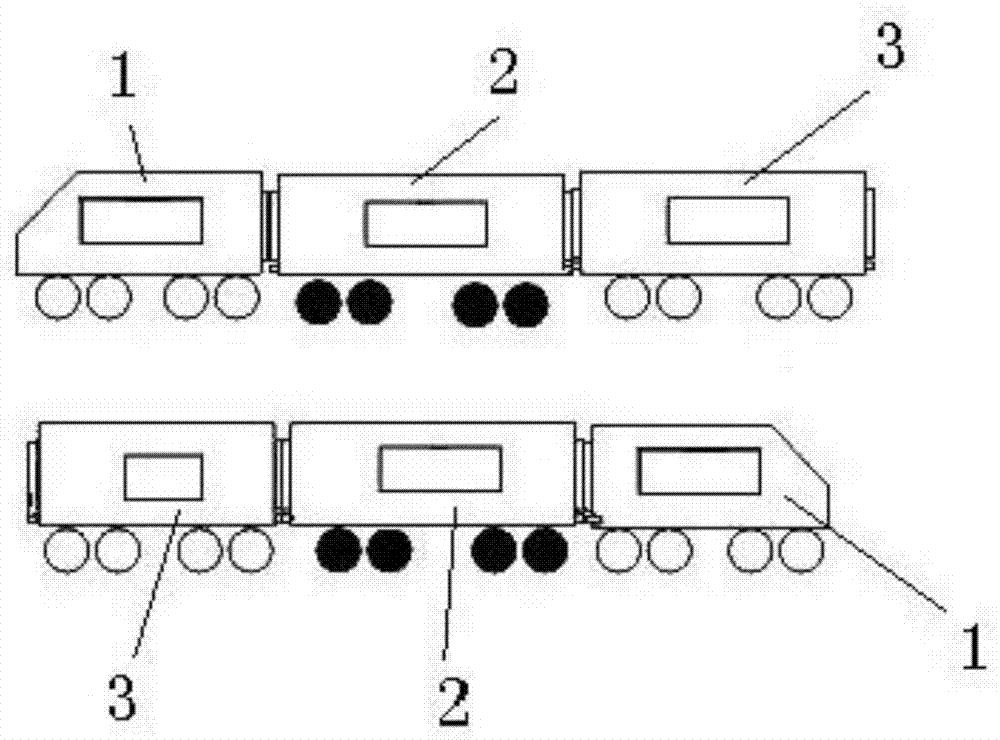

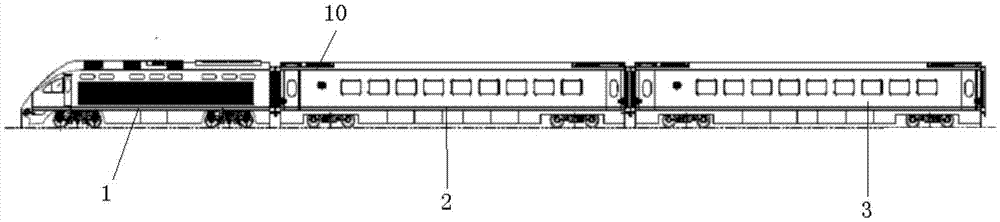

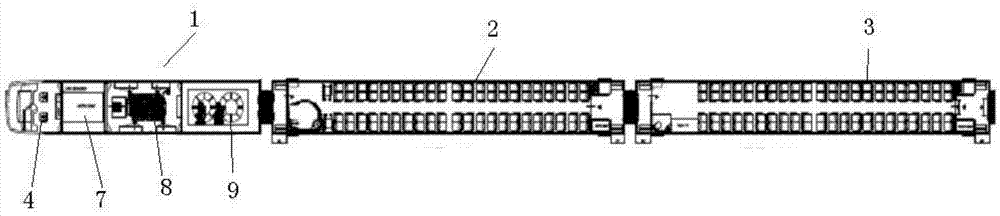

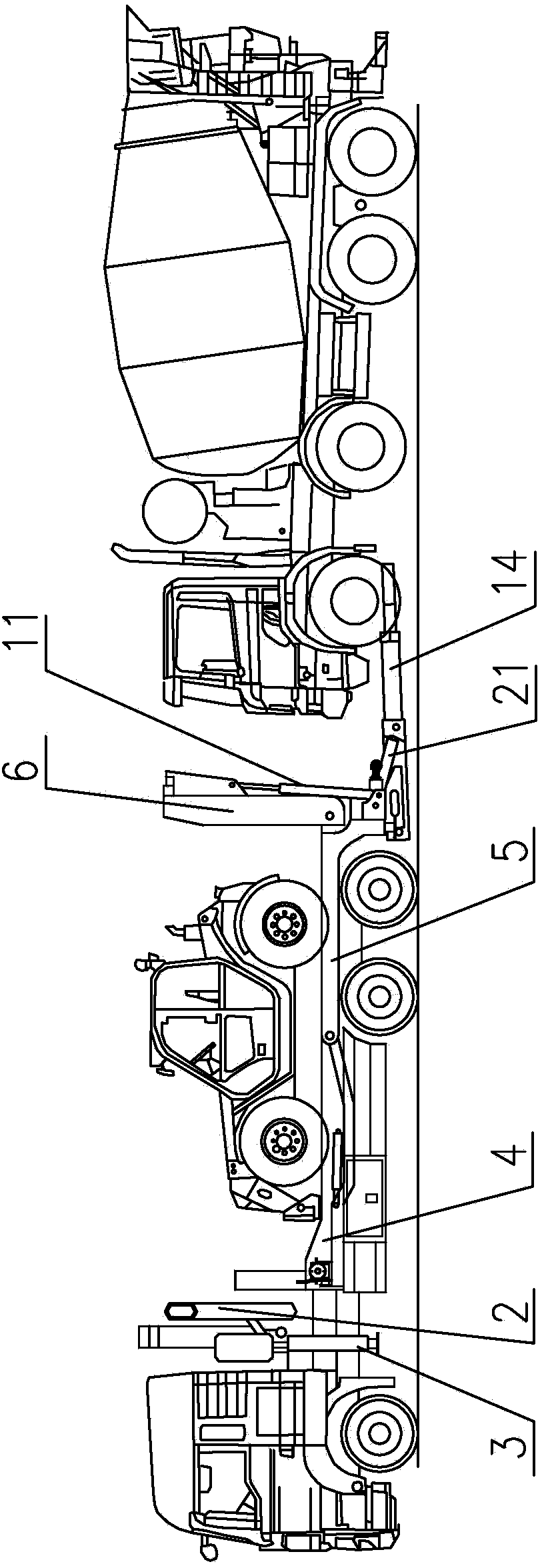

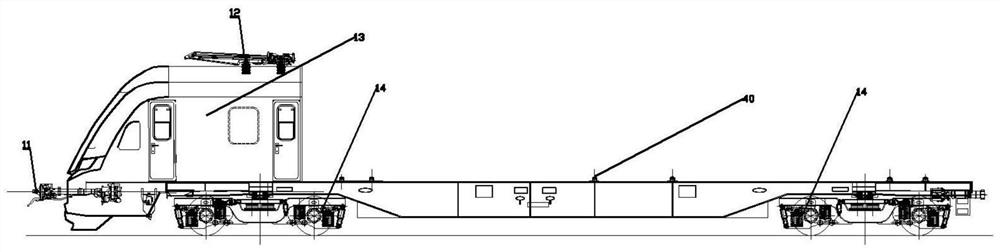

Internal-combustion high-speed motor train unit

InactiveCN105438188AMeet high power demandsReduce shockIC engine locomotivesIC reciprocating piston engine transmissionCombustionActuator

The invention provides an internal-combustion high-speed motor train unit which comprises a power towing carriage, a motor train unit carriage for carrying passengers as well as a trailer carriage connected with the motor train unit carriage for carrying passengers, wherein the power towing carriage comprises a power towing device and is used for towing the motor train unit carriage and the trailer carriage to run; the motor train unit carriage is connected with the power towing carriage, comprises an electric actuator, and is used for towing the trailer carriage to run through the electric actuator under the towing of the power towing carriage; and the trailer carriage is connected with the motor train unit carriage and runs under the towing of the power towing device and the electric actuator. According to the internal-combustion high-speed motor train unit provided by the invention, by adopting a form of separately arranging the power towing device and the electric actuator, the requirement for large power of the high-speed motor train unit is met, and the axle load is simultaneously reduced so as to enable the internal-combustion high-speed motor train unit to be practical and industrialized possibly, thereby greatly reducing the impact on lines and effectively reducing the construction and maintenance cost of the lines.

Owner:CRRC TANGSHAN CO LTD

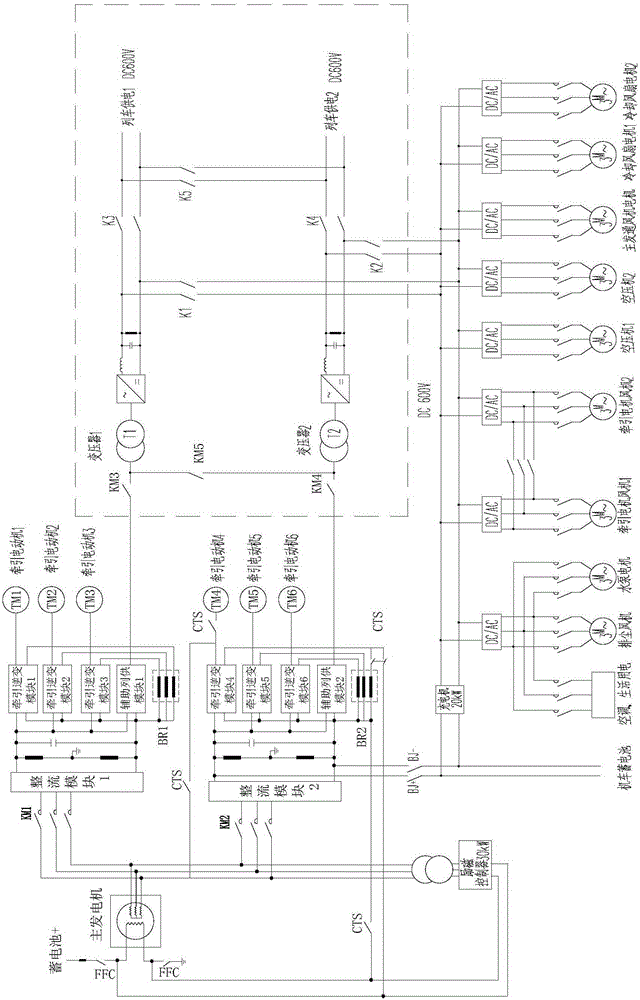

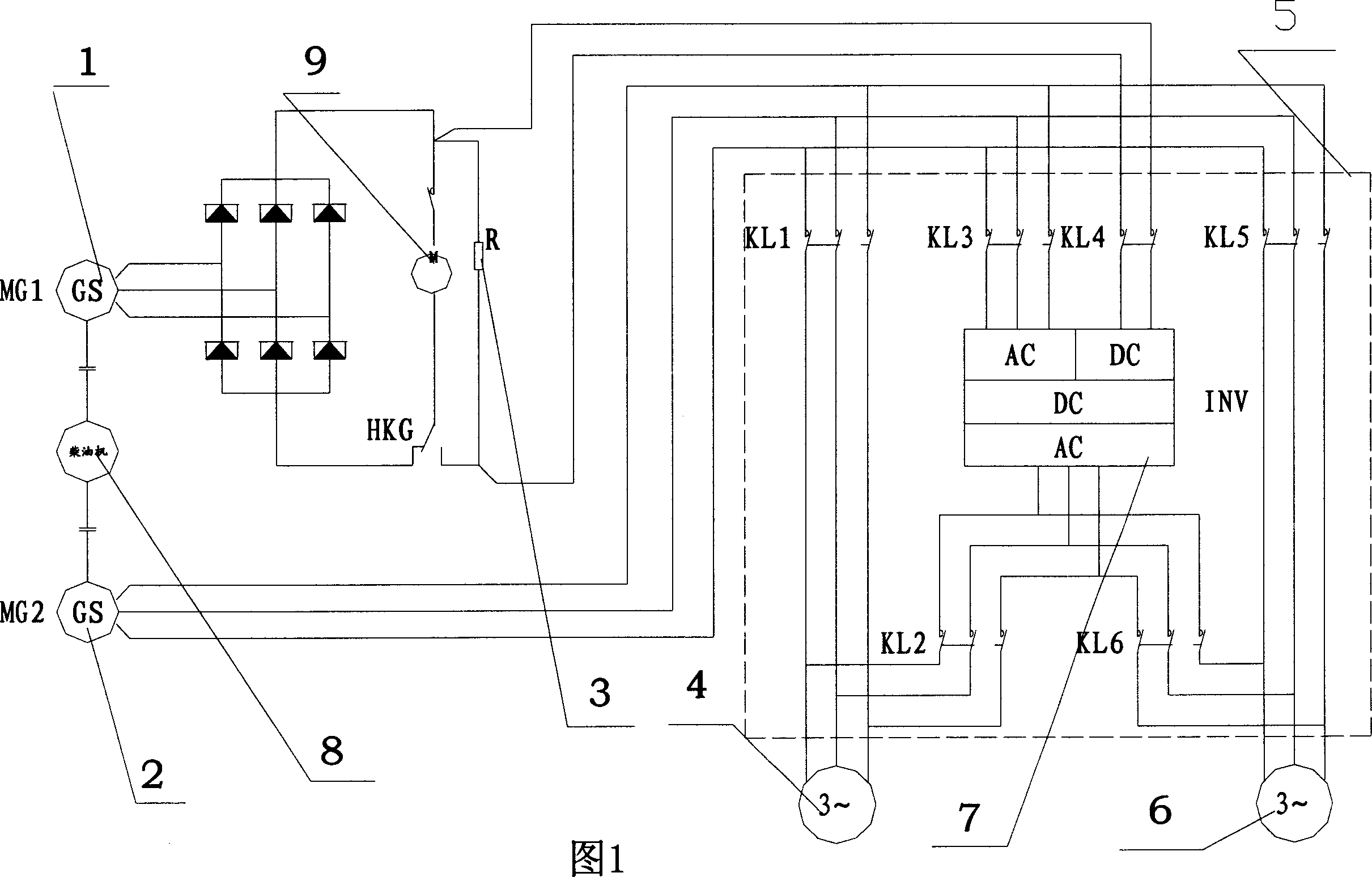

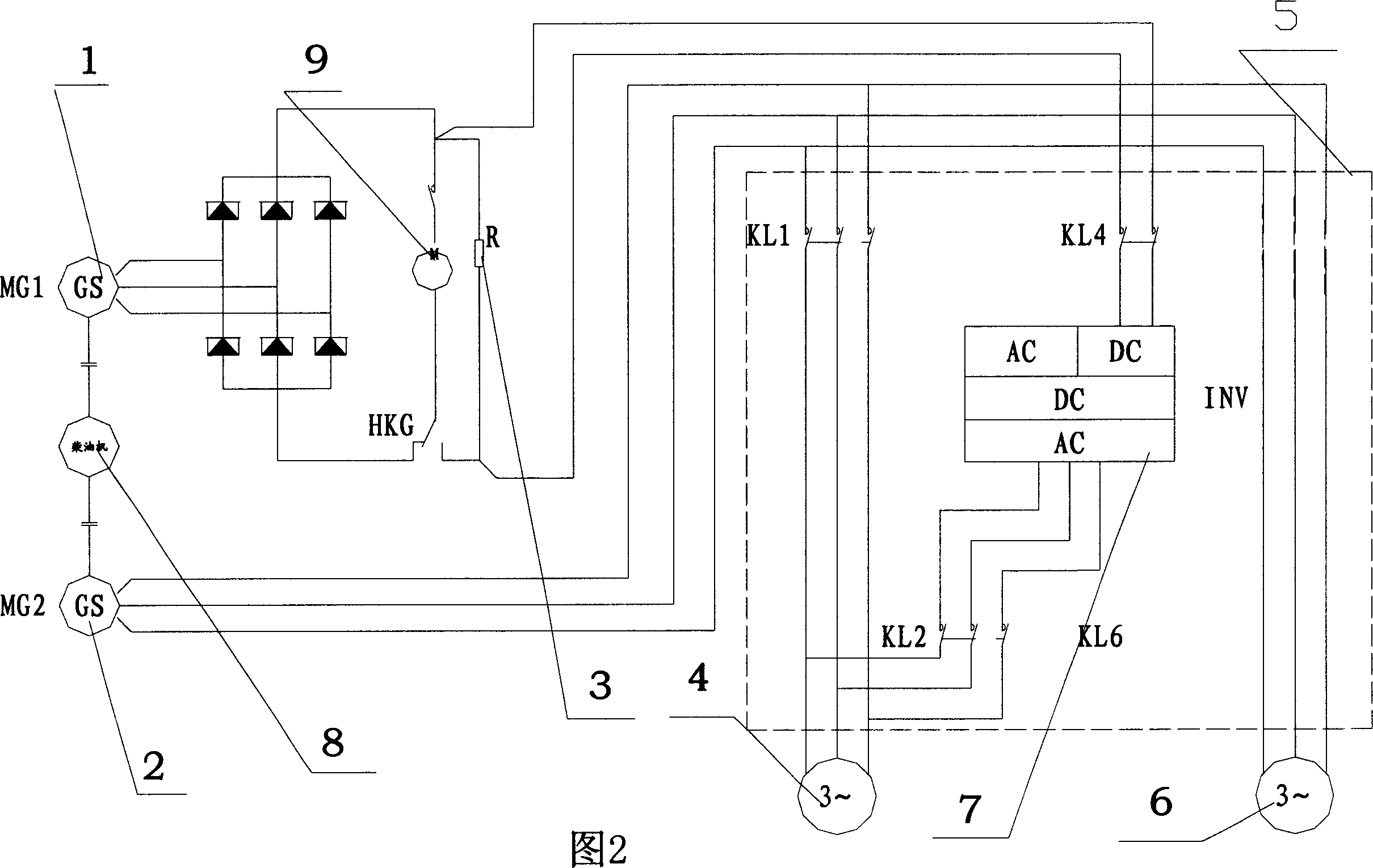

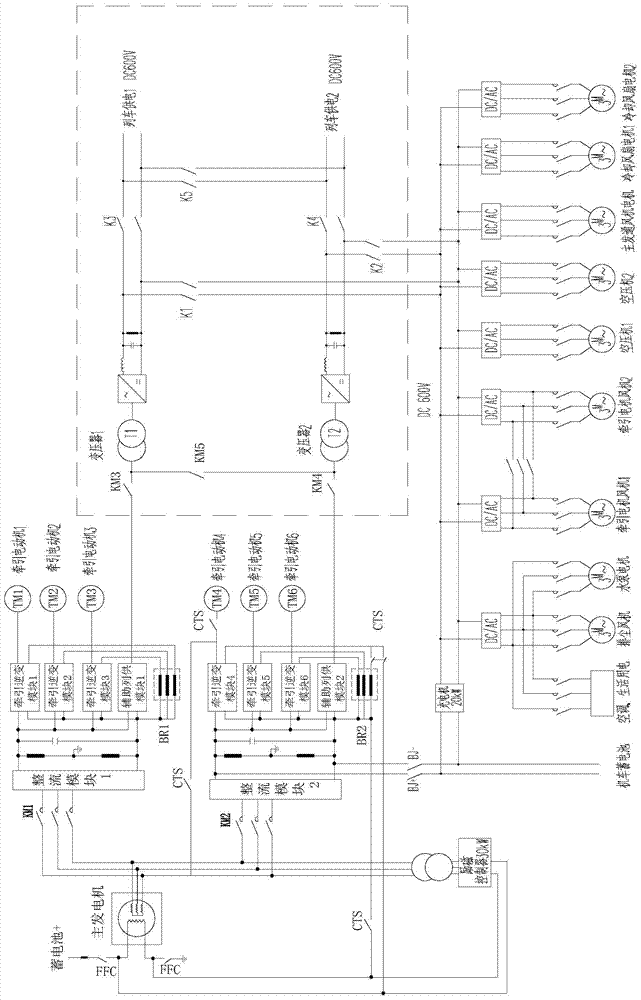

Diesel locomotive AC auxiliary system having train power supplying function

ActiveCN105216630AReduce axle loadRealize real-time distributionElectric powerElectric energy managementTransformerDiesel locomotive

The invention provides a diesel locomotive AC auxiliary system having a train power supplying function. The auxiliary system comprises a train main generator, a main conversion system and traction motors. The train main generator supplies power for the traction motors through the main conversion system. The auxiliary system also comprises a train power supply cabinet and an auxiliary conversion cabinet. Electric energy output by the main conversion system is sent to a conversion module in the auxiliary conversion cabinet after the electric energy passes through transformers and inverters in the train power supply cabinet, and the conversion module supplies power for loads of the auxiliary system. The auxiliary system can distribute traction electric energy and train power supply energy in a real-time manner. According to the invention, the train power supply can serve as the load for traction motor feedback braking, and the electric energy fed back to an intermediate DC link by the traction motors can provide electric power input for train power supplying. The auxiliary system is advantaged by high power supplying stability.

Owner:CRRC ZIYANG CO LTD

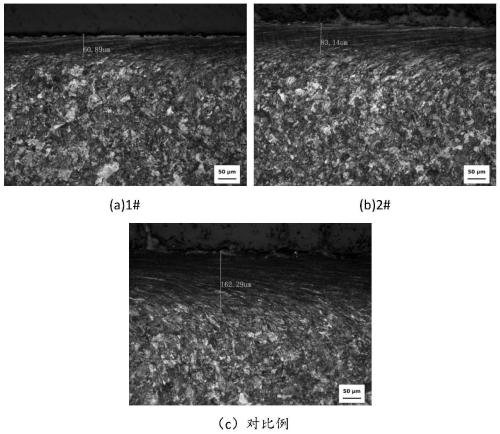

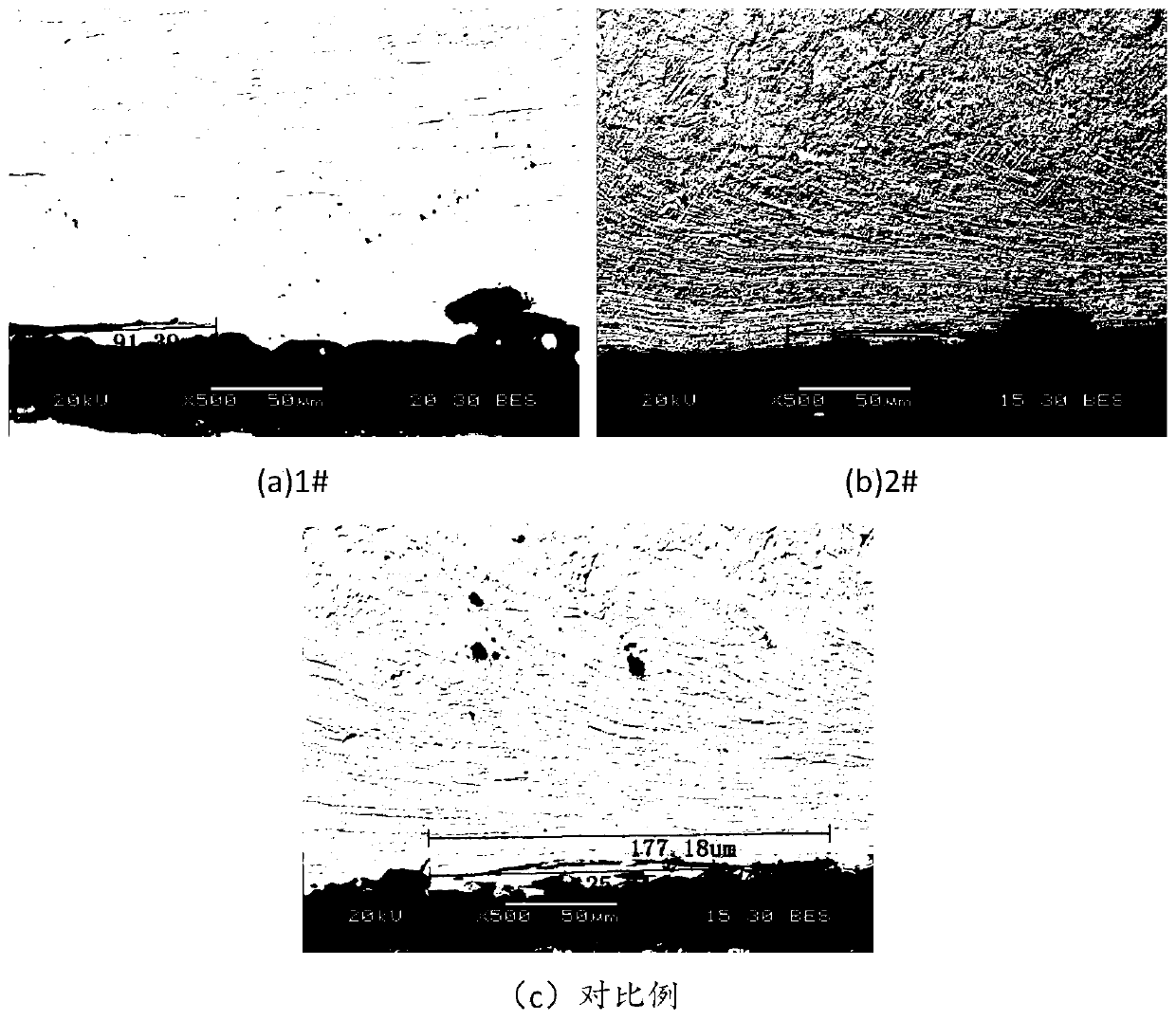

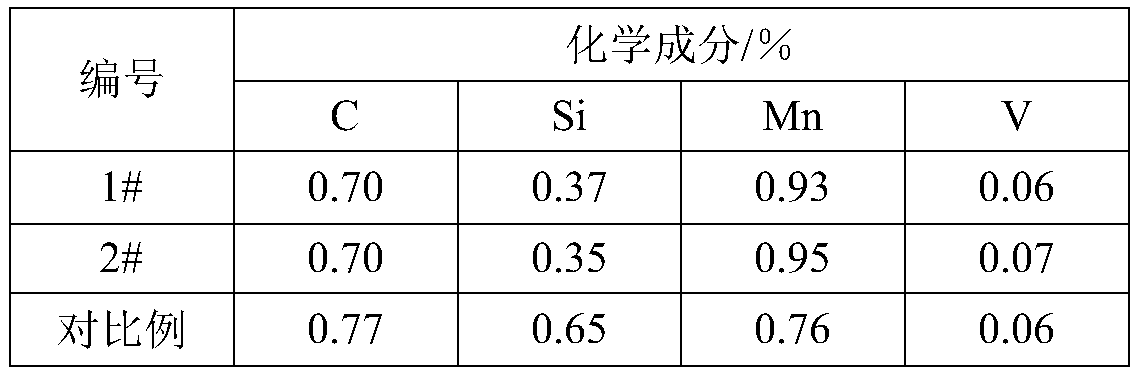

Steel rail for subways and preparation method of steel rail

InactiveCN111485174AExcellent resistance to contact fatigue damageReduce axle loadRailsFurnace typesCooling temperatureHeat treated

The invention relates to the field of steel rail materials, in particular to a steel rail for subways and a preparation method of the steel rail. According to the steel rail for the subways, on the basis of the total weight of a steel billet of the steel rail for the subways, the steel billet is prepared from 0.65%-0.75% of C, 0.20%-0.50% of Si, 0.80%-1.00% of Mn, 0.04%-0.10% of V and the balanceFe and inevitable impurities. The preparation method includes the following steps that the steel billet after heat insulation treatment is rolled, a waste-heat steel rail is obtained, quick cooling heat treatment is performed at the rail head part, heat treatment is divided into two sections, in the first section, the open cooling temperature is higher than 800 DEG C, the cooling rate is controlled to range from 4 DEG C / s to 5 DEG C / s for cooling, and in the second section, when the steel rail is cooled to the temperature ranging from 550 DEG C to 600 DEG C, the cooling rate is controlled to range from 1.5 DEG C / s to 2.5 DEG C / s for continuous cooling; and accelerated cooling is stopped when the temperature is reduced to be in the range of 440-460 DEG C, and then the steel rail is air-cooled to the room temperature. The steel rail has the excellent contact fatigue damage resistance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

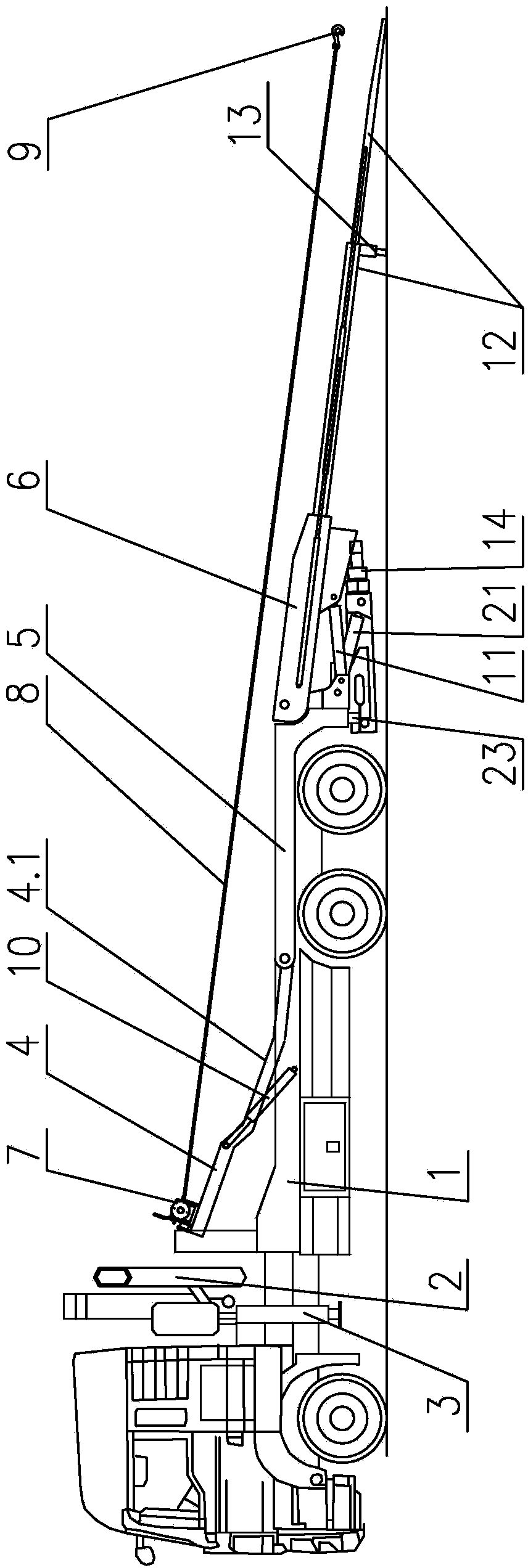

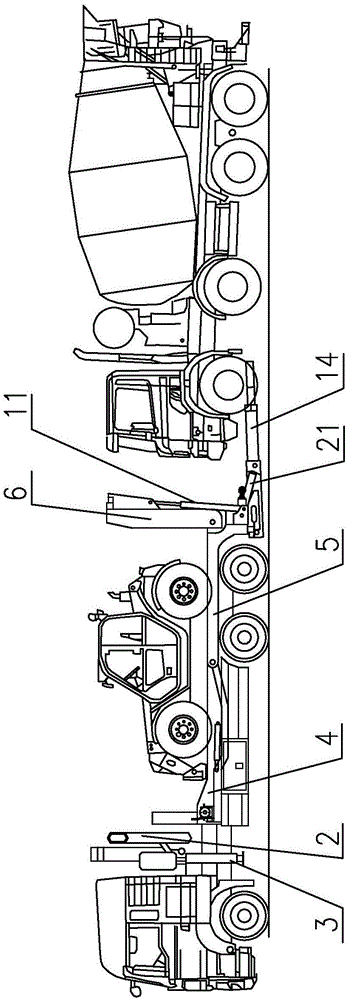

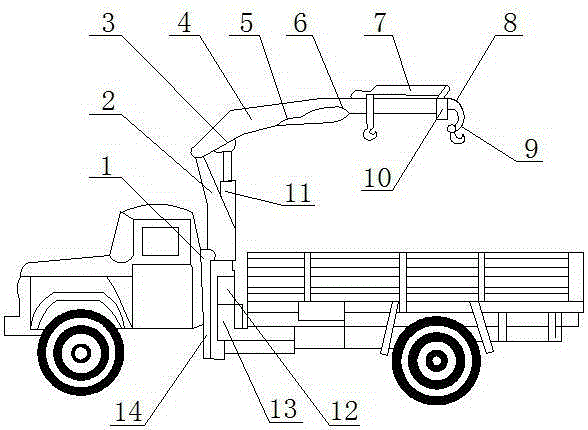

Multifunctional wrecker

ActiveCN103434434AEasy loadingGuaranteed minimum axle loadSalvaging damaged vehiclesLifting capacityEngineering

Owner:广东粤海汽车有限公司

Light weight, stiffened, twist resistant, extruded vehicle axle

ActiveUS7537290B2Increase beam intensityResist bending and flexingExtrusion diesExtrusion mandrelsTorsional loadMechanical engineering

Owner:AAM INT S A R L

Power supply control method of diesel locomotive auxiliary driving electric system and its device

ActiveCN1718466ASave fuelMeet the ventilation requirementsElectrodynamic brake systemsElectric powerDiesel locomotiveElectric machine

An electric power supplying method and device of the electric system in the auxiliary transmission system for diesel locomotive features that when the locomotive is in tractive state, the tractive ventilator is electrically powered by secondary electric generator, when it is in brake state, the traction motor is isolated from primary electric generator and the motor is modified as electric generator, when the generated potential is more than 230 VDC, the tractive ventilator is electrically powered by secondary current transformer, and the cooling fan is electrically powered by either secondary electric generator or current transformer.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

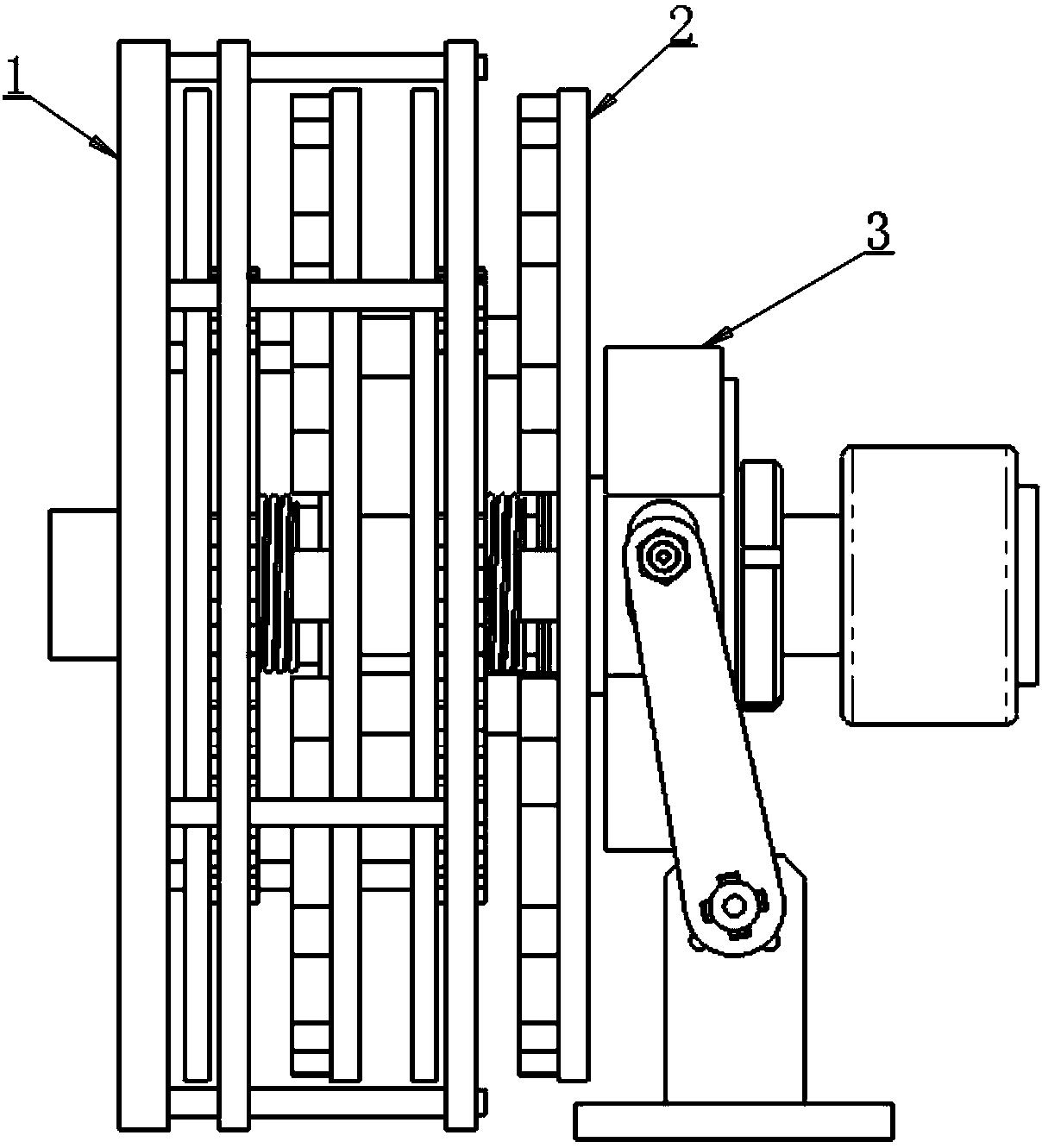

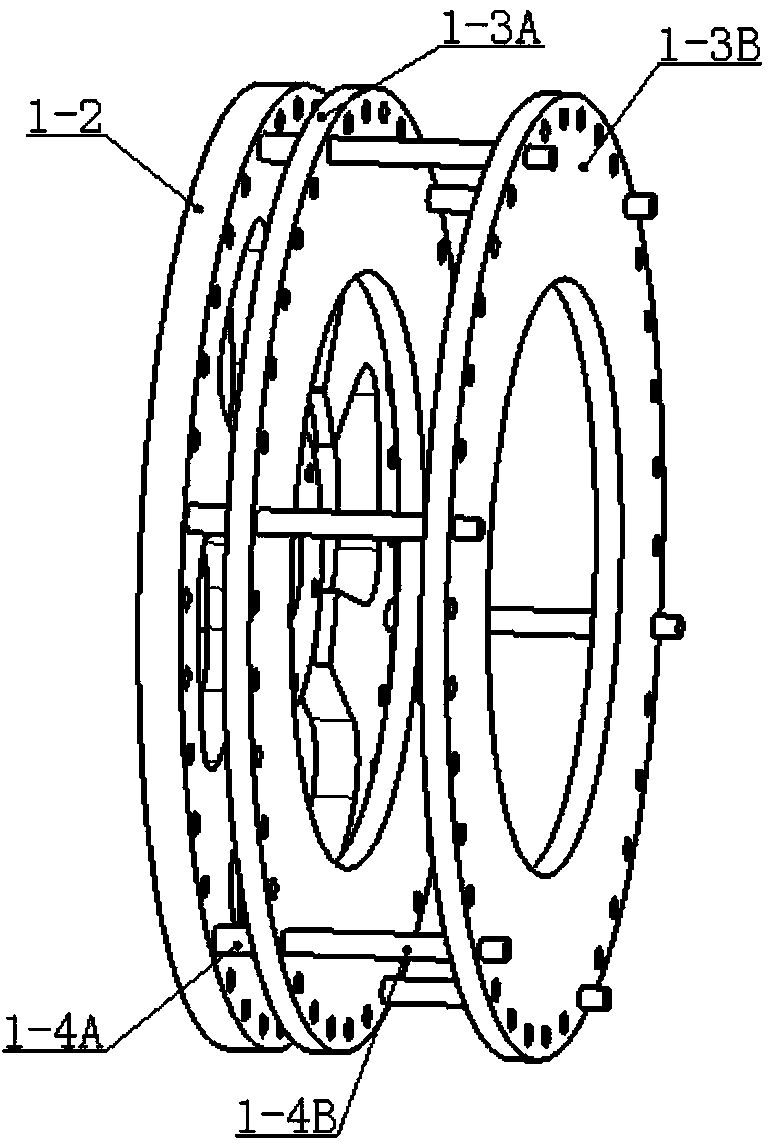

Self-feeding-type permanent magnet eddy current speed regulator

ActiveCN103915972AHeat dissipation directlyEfficient heat dissipationDynamo-electric gearsPermanent magnet rotorElectrical conductor

The invention discloses a self-feeding-type permanent magnet eddy current speed regulator. The self-feeding-type permanent magnet eddy current speed regulator comprises an auxiliary shaft and an extension main shaft which are coaxially arranged; permanent magnet rotor main disks and permanent magnet rotor auxiliary disks are arranged on the extension main shaft in parallel in a pairwise mode, and the sides, facing the permanent magnet rotor auxiliary disks, of the permanent magnet rotor main disks are provided with permanent magnet groups; one permanent magnet rotor main disk and one permanent magnet rotor auxiliary disk form a permanent magnet disk pair; each permanent magnet rotor auxiliary disk on a permanent magnet rotor is fixedly installed on the extension main shaft; each permanent magnet rotor main disk is installed on the extension main shaft in a sleeved mode and can rotate synchronously with the corresponding permanent magnet rotor auxiliary disk; a through hole is formed in the center of a conductor disk fixedly connected with the auxiliary shaft, and the conductor disk is arranged on the periphery of the extension main shaft in a sleeved mode and located between the permanent magnet rotor auxiliary disks and the permanent magnet rotor main disks. According to the self-feeding-type permanent magnet eddy current speed regulator, one or more groups of magnetic fields with the intensity capable of being adjusted simply are flexibly established on the permanent magnet rotor, and axial permanent magnet attractive force with destructive power does not exist between the permanent magnet rotor and a conductor rotor which are not in contact with each other.

Owner:西安巨舟电子设备有限公司

Titanium alloy and application of titanium alloy to machining of train connecting piece

The invention discloses a titanium alloy. The titanium alloy comprises the following components by weight percentage: 3.8-4.8% of Al, 2.0-3.2% of V, 0.7-1.7% of Fe, 0.2-0.3% of O and the balance of Ti. Machining steps are as follows: step (1), heating a titanium alloy ingot in a temperature range of 100-150 DEG C above a phase transformation point, controlling the final forging temperature in a range of 900 DEG C + / -20 DEG C, performing cogging forging, and controlling rolling reduction at every time within 10-25 mm; step (2), heating in a temperature range of the phase transformation point + / - 20 DEG C, performing upsetting and drawing forging, and controlling the final forging temperature in a range of 850 DEG C + / -20 DEG C and the rolling reduction not to excess 30%of the length; step (3), heating at 30-50 DEG C below the phase transformation point, performing finished-product forging, controlling deformation to be about 60%, and performing heat treatment after the finished-product forging; step (4), performing vacuum annealing as the heat treatment, controlling the annealing temperature to be in a range of about 150 DEG C within the phase transformation point, controlling the temperature changeless to be 60-90 min, and performing air cooling. The titanium alloy is applied to manufacturing of a drive pin, a connecting rod, a motor suspending lever and a fastening of a train or a motor car; weight losing and corrosion resisting effects are achieved.

Owner:沈阳泰恒通用技术有限公司

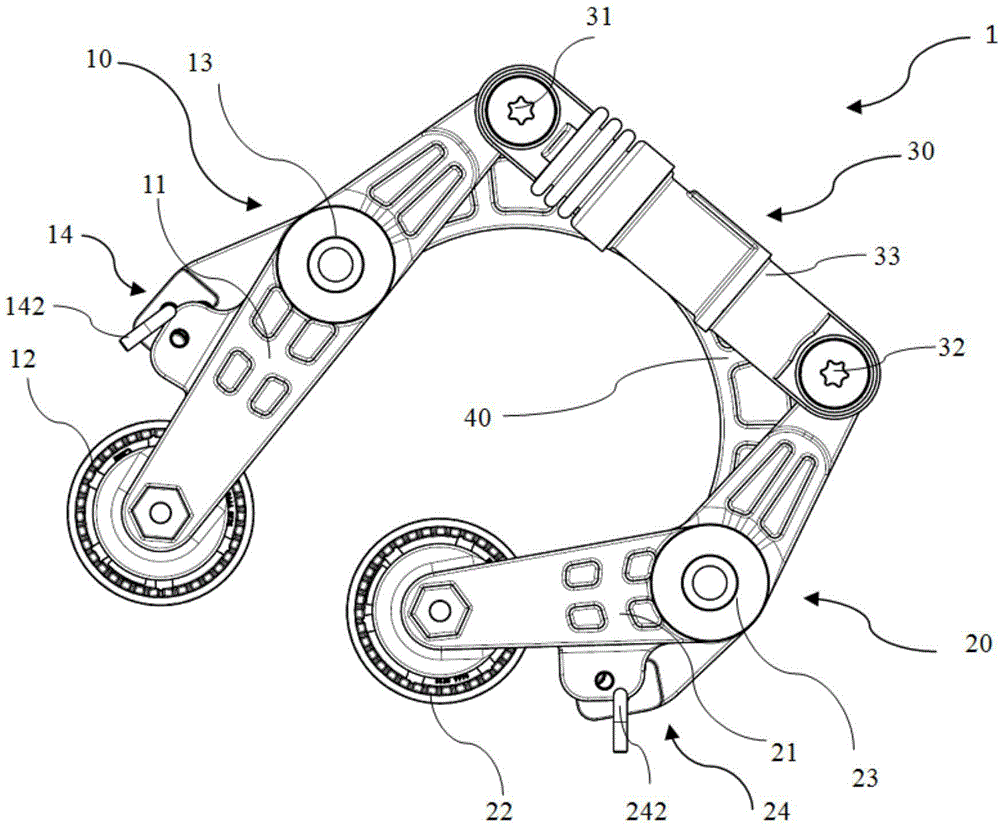

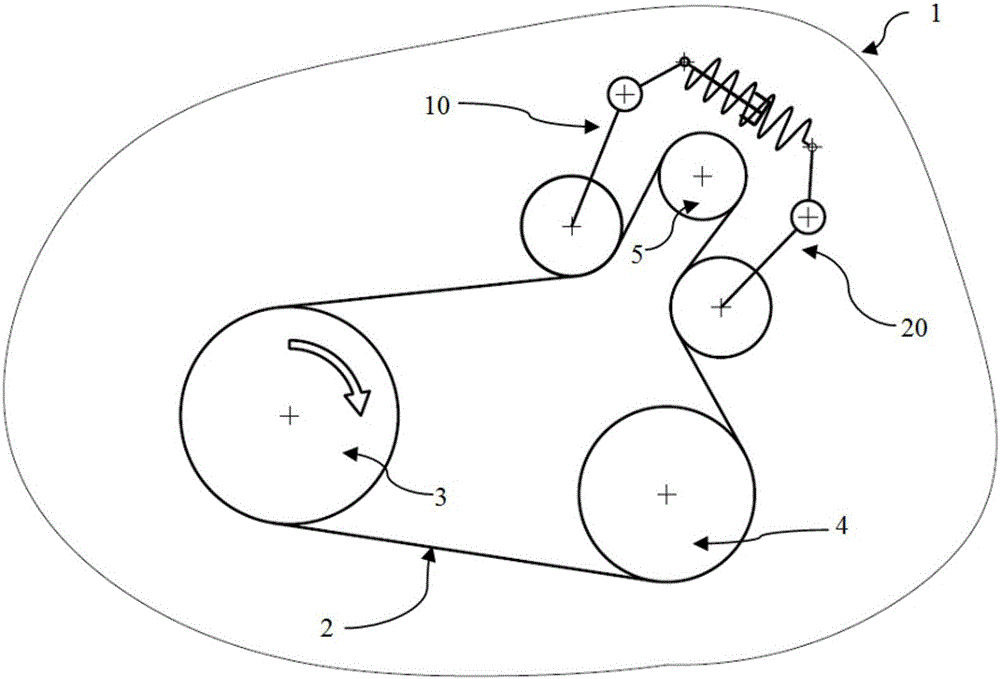

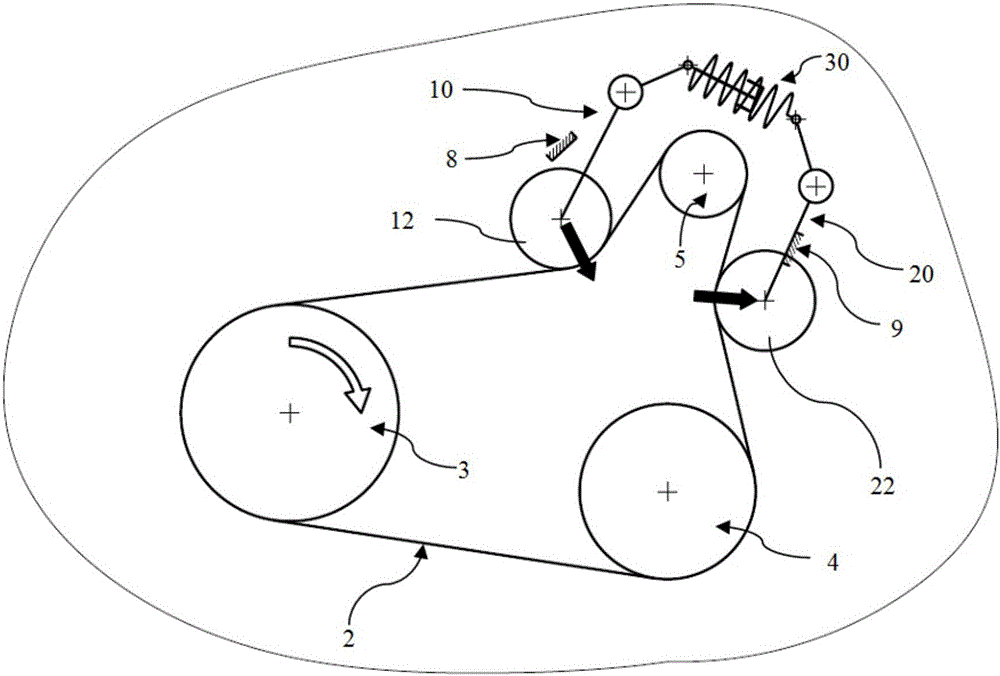

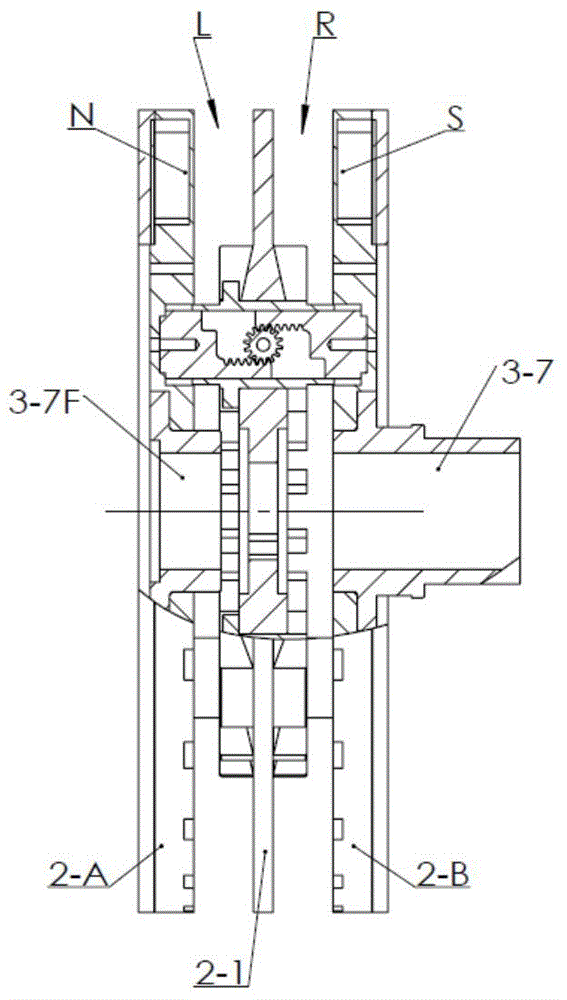

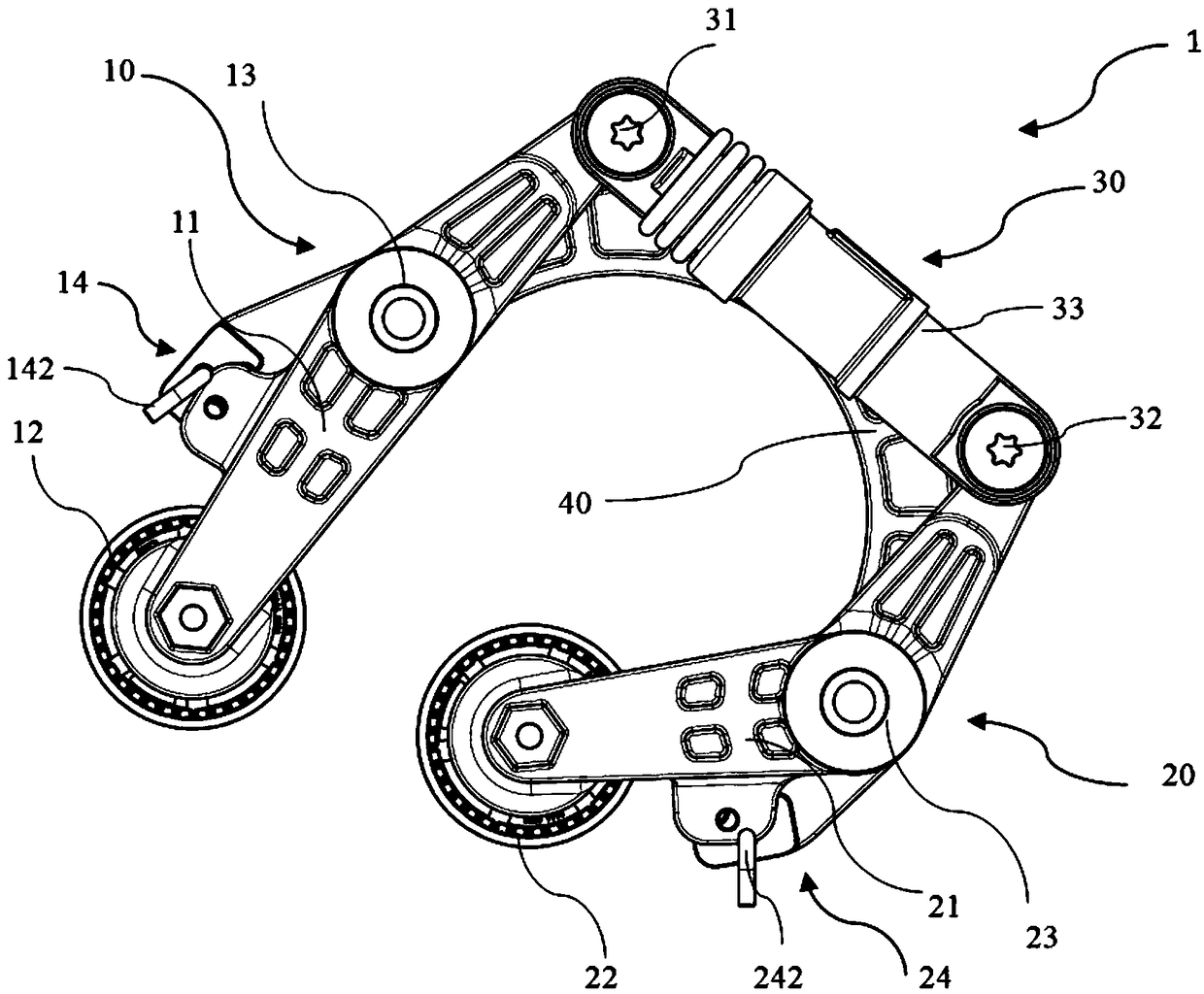

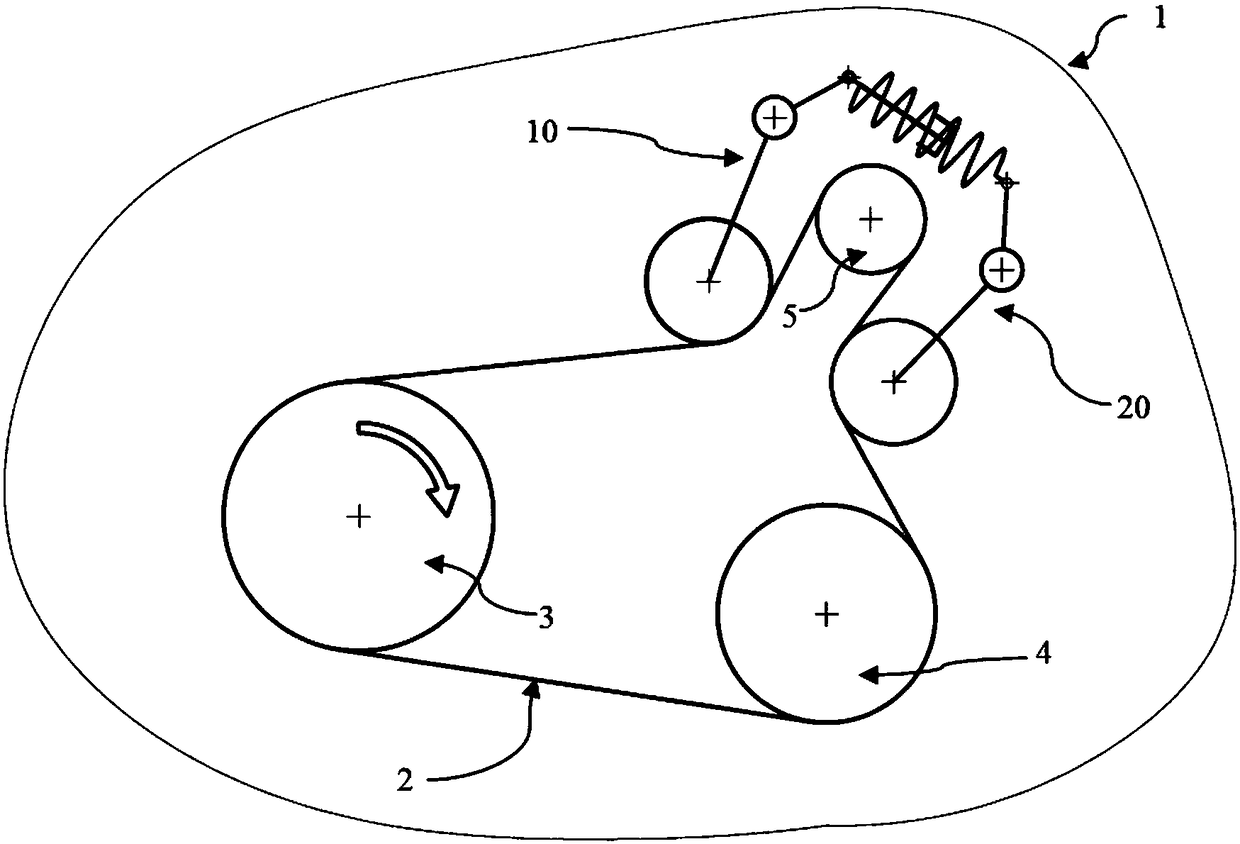

Bidirectional association bidirectional tensioning device with variable damping device

Owner:NINGBO FENGMAO FAR EAST RUBBER

Three-axle power bogie based on 100% low-floor tramcar

InactiveCN104709308AImprove adhesionImproved climbing ability and accelerationBogiesPower steeringBogie

The invention discloses a three-axle power bogie based on a 100% low-floor tramcar. The three-axle power bogie comprises a rectangular framework, wheel set devices, primary suspensions, secondary suspensions, vertical dampers and transverse dampers. The three wheel set devices are arranged on the rectangular framework forwards and backwards at intervals, axles corresponding to the wheel set devices located on the front side and the rear side are power drive shafts, an axle corresponding to the wheel set device located in the middle is a non-power drive shaft, one side of each power drive shaft is provided with a power drive device, the other side of each power drive shaft is provided with a braking device and a grounding device, the two sides of the non-power drive shaft are provided with braking devices, and the two power drive devices are installed outside different side beams of the rectangular framework and arranged in a skew symmetry mode. The parts except for the power drive devices and the transverse dampers are symmetrically distributed according to the center point of the rectangular framework. Under the same load condition, compared with a two-axle bogie, the whole car acceleration is high, climbing capacity is high, adhesive force is large, and axle loads are effectively reduced.

Owner:CHONGQING HENGTONG BUS

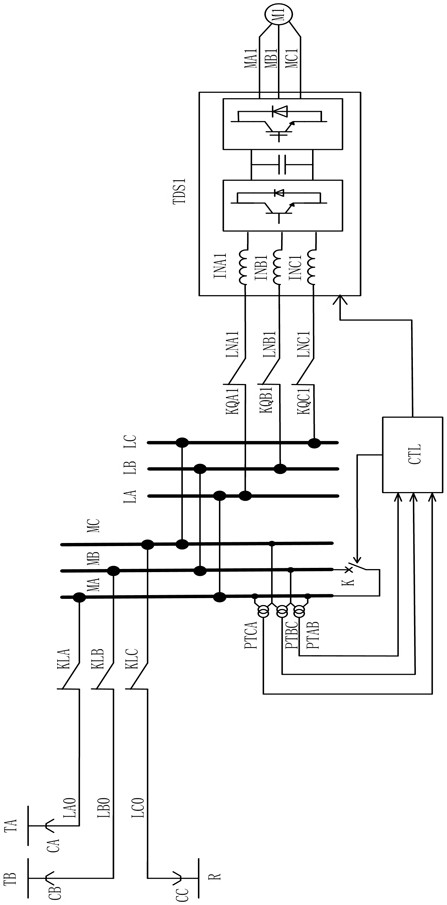

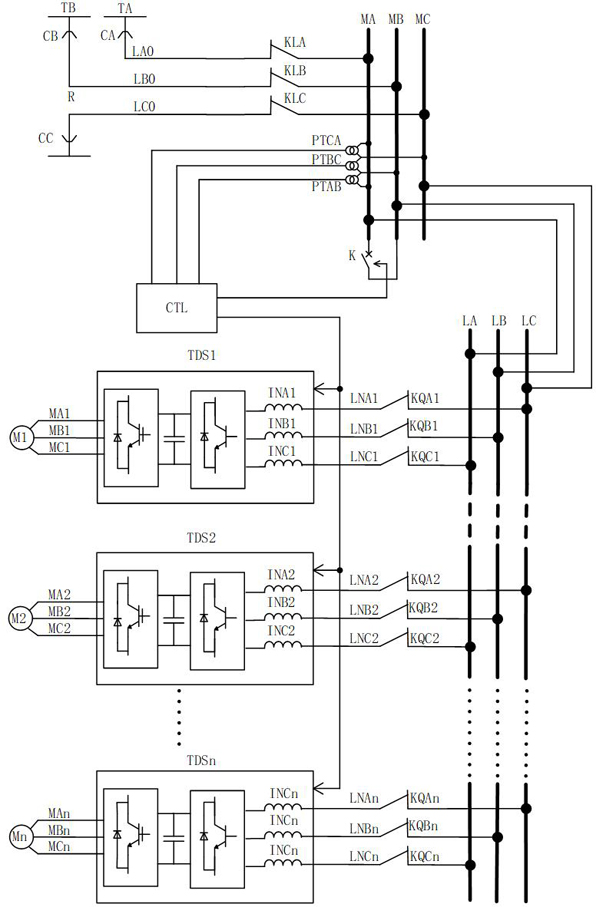

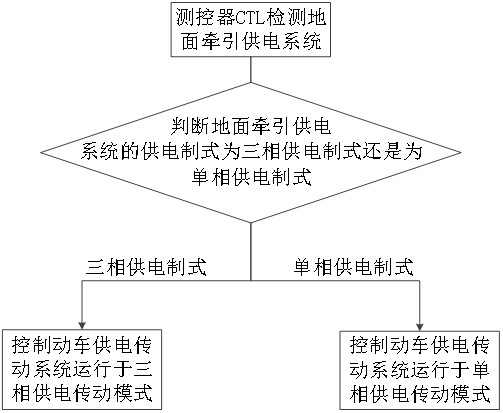

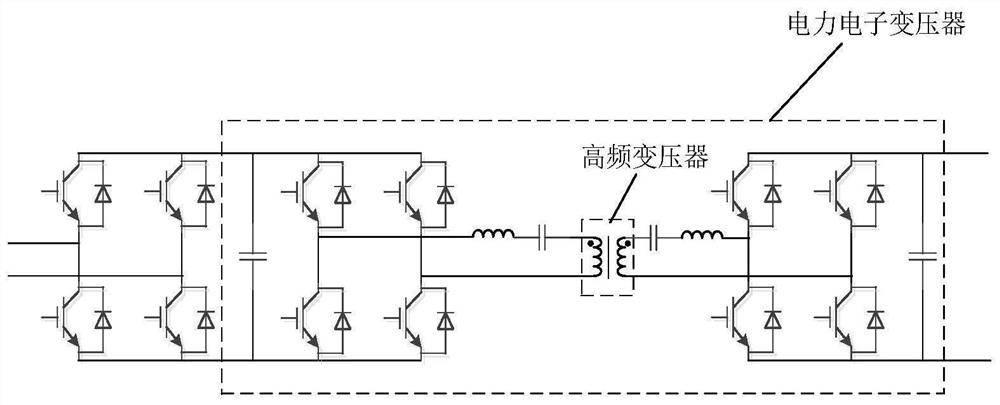

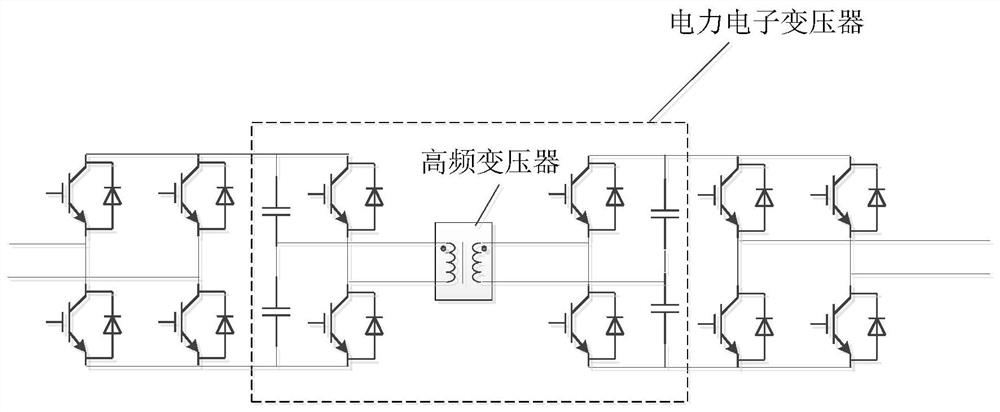

Bullet train power supply transmission system, AC-DC-AC traction converter and control method thereof

ActiveCN113799663AFlexible designImprove compatibilityPower supply linesRemote controlTraction power supply

The invention provides a bullet train power supply transmission system which is divided into a three-phase power supply transmission mode and a single-phase power supply transmission mode, and the power supply capacities of the two modes are equal. Through automatic identification or cab remote control, when the ground traction power supply system is in the three-phase power supply mode, the bullet train power supply transmission system is automatically switched to the three-phase power supply transmission mode, and when the ground traction power supply system is in the single-phase power supply mode, the bullet train power supply transmission system is automatically switched to the single-phase power supply transmission mode. The mode switching is matched with the three-phase power supply system and the single-phase power supply system of the ground traction power supply system so that the compatibility of the three-phase power supply transmission system and the single-phase power supply transmission system of the bullet train can be conveniently and effectively realized.

Owner:SOUTHWEST JIAOTONG UNIV

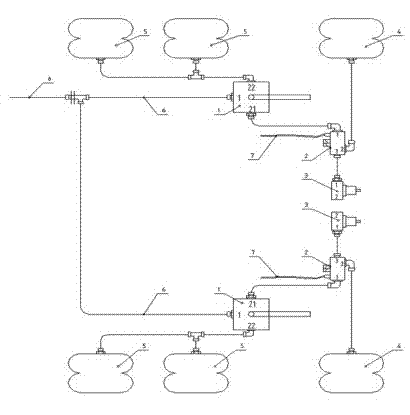

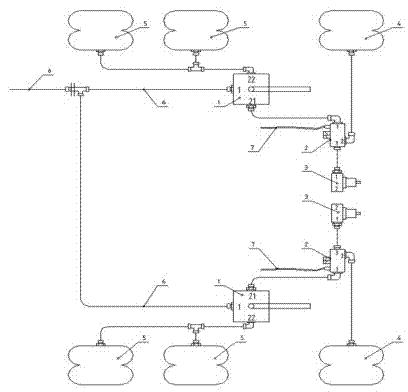

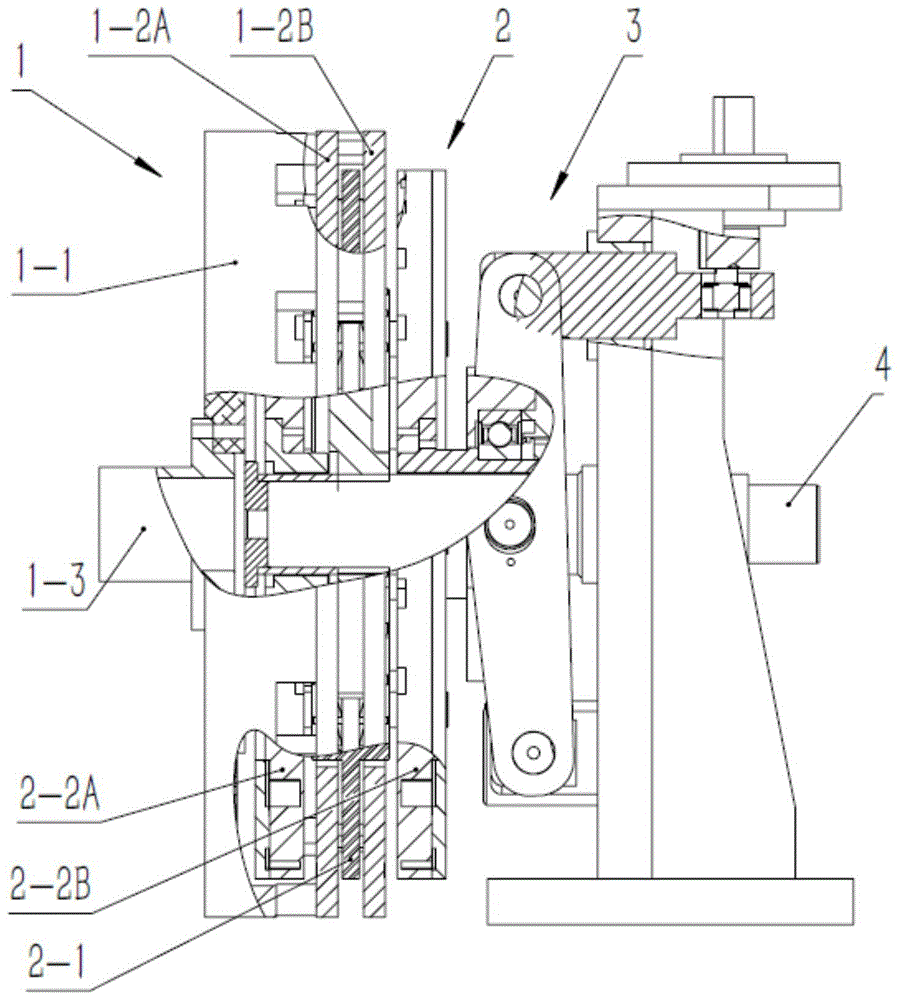

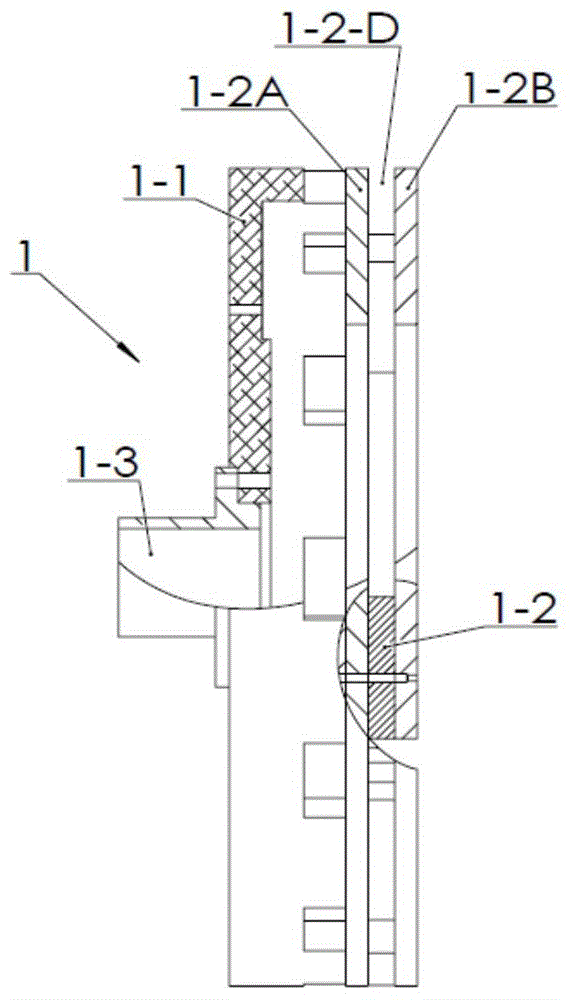

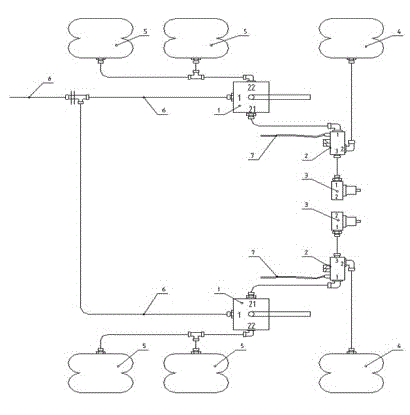

Rear axle airbag inflating and deflating system and three-axle vehicle using same

The invention relates to a rear axle airbag inflating and deflating system and a three-axle vehicle using same. The system comprises an airbag height control valve, a rear axle airbag, a normally open solenoid valve and an overflowing valve; a normally open hole of the normally open solenoid valve is connected with an air outlet of the airbag height control valve, while the other normally open hole is connected with an air inlet of the rear axle airbag; a normally close hole of the normally open solenoid valve is connected with an air inlet of the overflowing valve, and a control interface of the normally open solenoid valve is connected with a reverse gear signal circuit of the three-axle vehicle; and the normally open solenoid valve is controlled to be opened or closed to realize the function of automatically inflating and deflating the rear axle airbag according to a reverse gear signal. The rear axle airbag inflating and deflating system is simple to realize and low in cost, and the three-axle vehicle using the system can reduce the rear axle load without changing the existing suspension structure thereof in the braking process, thereby reducing abrasion of the rear axle tire.

Owner:ZHENGZHOU YUTONG BUS CO LTD

Permanent magnet eddy current speed controller based on conjugated magnetic feed rotor

ActiveCN104377933ANo axial permanent magnetic attractionEfficient air coolingDynamo-electric gearsPermanent magnet rotorElectrical conductor

The invention discloses a permanent magnet eddy current speed controller based on a conjugated magnetic feed rotor. The permanent magnet eddy current speed controller comprises an auxiliary shaft and an extension main shaft, the auxiliary shaft and the extension main shaft are coaxially arranged, the extension main shaft is provided with a permanent magnet plate A, the conjugated magnetic feed rotor and a permanent magnet plate B in parallel, the auxiliary shaft is fixedly provided with a conductor rotor base plate, a conductor plate A and a conductor plate B are fixed to the conductor rotor base plate in parallel, the conductor plates are located between the conjugated magnetic feed rotor and the permanent magnet plates, and the permanent magnet plate A and the permanent magnet plate B are connected with a displacement regulating mechanism which drives the permanent magnet plate A and the permanent magnet plate B to move along the extension main shaft axially and synchronously in opposite directions. A more ingenious topological method is adopted and combined with a feasible optimized electromagnetic and mechanical structure, so that the permanent magnet speed controller based on the conjugated magnetic feed rotor is formed. Two magnetic fields with strength capable of being simply adjusted are formed only on the permanent magnet rotor, and no destructive magnetic acting force exists between the permanent magnet rotor and a conductor rotor which make no contact with each other.

Owner:西安巨舟电子设备有限公司

A diesel locomotive AC auxiliary system with train power supply function

ActiveCN105216630BReduce axle loadRealize real-time distributionElectric powerElectric energy managementDiesel locomotiveTransformer

The invention provides a diesel locomotive AC auxiliary system having a train power supplying function. The auxiliary system comprises a train main generator, a main conversion system and traction motors. The train main generator supplies power for the traction motors through the main conversion system. The auxiliary system also comprises a train power supply cabinet and an auxiliary conversion cabinet. Electric energy output by the main conversion system is sent to a conversion module in the auxiliary conversion cabinet after the electric energy passes through transformers and inverters in the train power supply cabinet, and the conversion module supplies power for loads of the auxiliary system. The auxiliary system can distribute traction electric energy and train power supply energy in a real-time manner. According to the invention, the train power supply can serve as the load for traction motor feedback braking, and the electric energy fed back to an intermediate DC link by the traction motors can provide electric power input for train power supplying. The auxiliary system is advantaged by high power supplying stability.

Owner:CRRC ZIYANG CO LTD

multifunctional wrecker

ActiveCN103434434BEasy loadingGuaranteed minimum axle loadSalvaging damaged vehiclesLifting capacityEngineering

Owner:广东粤海汽车有限公司

Rear axle airbag inflating and deflating system and three-axle vehicle using same

Owner:ZHENGZHOU YUTONG BUS CO LTD

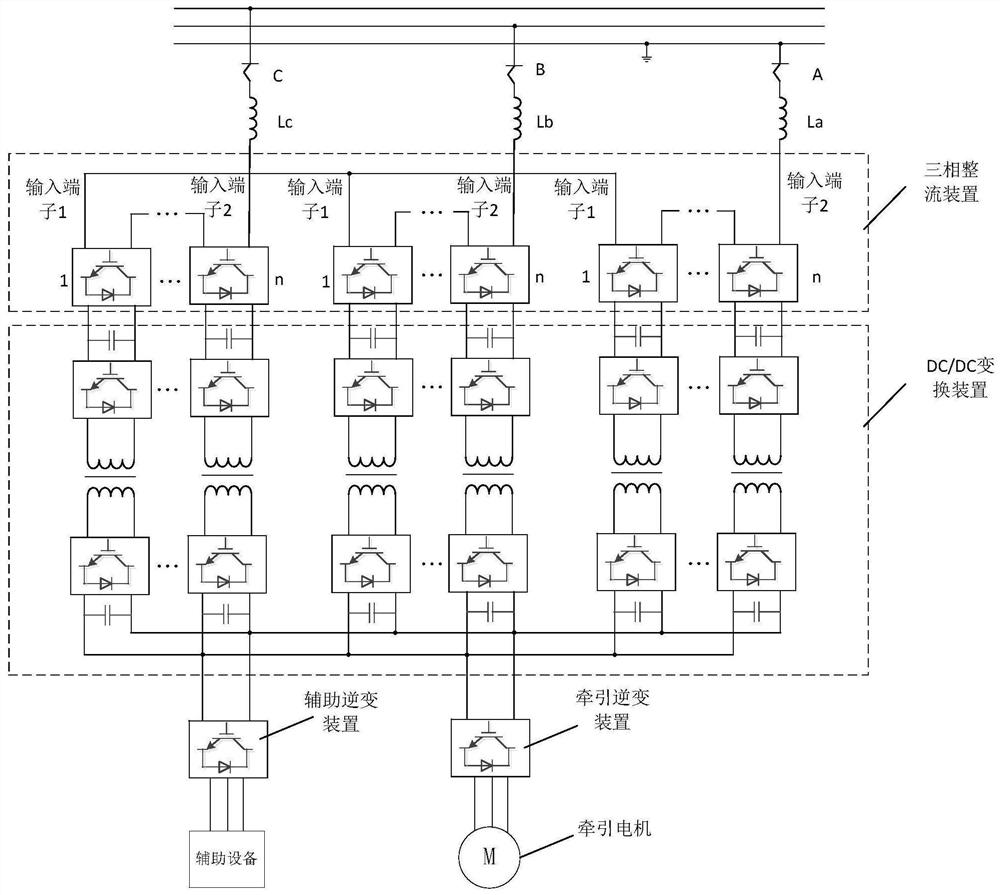

Three-phase motor train unit traction transmission power supply system

PendingCN113895241AReduce volumeReduce weightPropulsion using ac induction motorsRailway vehiclesElectric machineTraction transformer

The invention provides a three-phase motor train unit traction transmission power supply system which comprises a three-phase rectifying device, a DC / DC conversion device, and a traction inversion device ; the three-phase rectifying device comprises a three-phase alternating-current input port and three direct-current output port sets, each direct-current output port set comprises n direct-current output ports, n is larger than or equal to 1, and the number of n is set according to the voltage level of an external three-phase power source; the DC / DC conversion device comprises 3n independent power electronic transformers, the input port of each power electronic transformer is correspondingly connected with one direct current output port of the three-phase rectifying device, and the output ports of the power electronic transformers are connected in parallel and then serve as the direct current output port of the DC / DC conversion device; the input port of the traction inversion device is connected with the direct current output port of the DC / DC conversion device, and the output port of the traction inversion device is electrically connected with a traction motor. The three-phase rectifying device is directly used for taking electricity from the external power supply to drive the traction motor, a vehicle-mounted traction transformer can be omitted, the value of n can be set according to different voltage grades, and the applicable voltage grade range is wide.

Owner:CHENGDU SHANGHUA ELECTRIC CO LTD

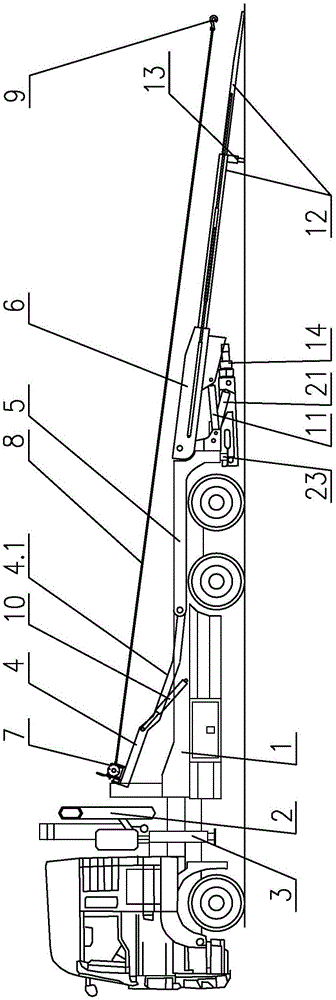

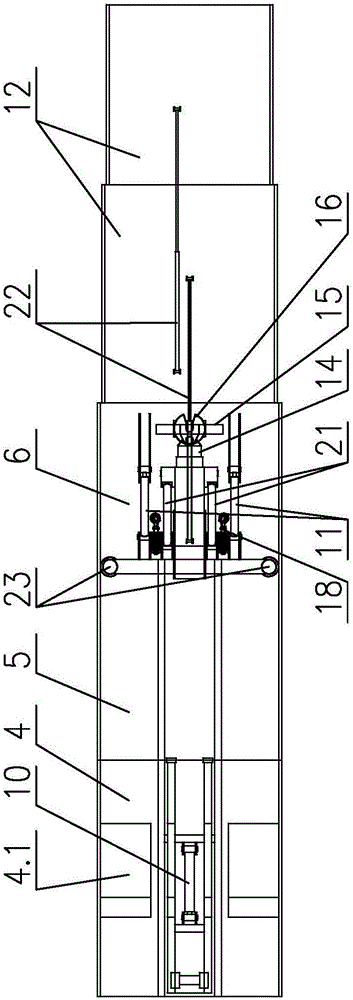

Small-sized autocrane

The invention provides a small-sized autocrane which comprises an operating valve, a bracket, a loading limit rod, a lower knuckle arm, a foldable hydraulic cylinder, an upper knuckle arm, a telescopic hydraulic cylinder, a telescopic arm, a lifting hook, a middle arm, a lifting hydraulic cylinder, a swing mechanism, a rack and a supporting leg, wherein the bracket is arranged at the top of the operating valve; one end of the bracket is in close contact with the lifting hydraulic cylinder; the loading limit rod is arranged on one side of the lifting hydraulic cylinder, and is arranged at one end of the lower knuckle arm; the foldable hydraulic cylinder is arranged on one side of the lower knuckle arm; the foldable hydraulic cylinder is in close connection with the upper knuckle arm; the telescopic hydraulic cylinder is arranged on one side of the upper knuckle arm; the telescopic arm is fixedly connected with the tail end of the telescopic hydraulic cylinder; the lifting hook is arranged at one end of the telescopic arm. Pressure on the road surface by a vehicle below the autocrane is reduced, and a lifting arm does not need to be unloaded from the vehicle to be independently transported; compared with the conventional large-size autocrane, the labor is saved, the transportation cost is reduced, and the work efficiency is improved.

Owner:WUXI GANGSHENG HEAVY EQUIP CO LTD

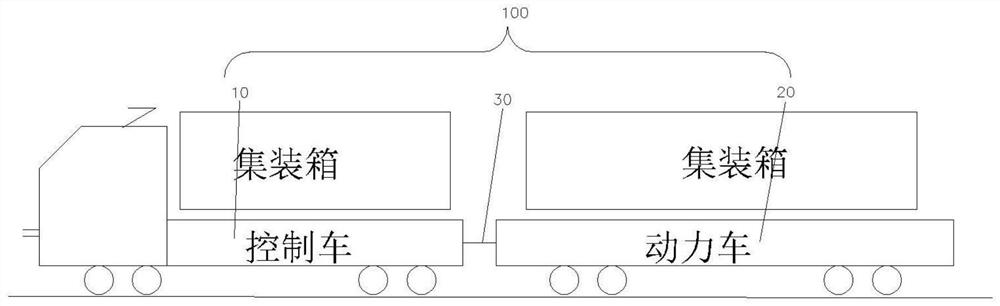

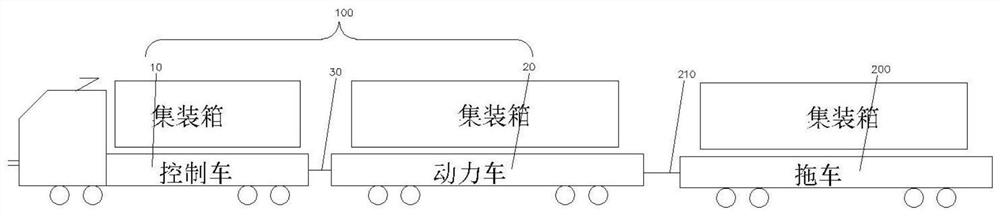

Locomotive unit, freight locomotive and freight locomotive management method

ActiveCN113401154AReduce axle loadMeet transportation needsWagons/vansRailway coupling accessoriesBogieMode of transport

The invention discloses a locomotive unit. The locomotive unit comprises a control vehicle, a power vehicle and a first connecting mechanism, one end of the control vehicle is connected with the power vehicle through the first connecting mechanism, the control vehicle comprises a control vehicle body, a non-power bogie and a first container locking device, and the power vehicle comprises a power vehicle body, a power bogie and a second container locking device. In addition, the invention discloses a corresponding freight locomotive and a management method of the freight locomotive. Firstly, axle load information of a transportation line is obtained, the maximum traction weight of the locomotive unit is calculated, then the required traction weight is obtained according to the difference between the total output cargo transportation amount and the self-loading weight, and according to the maximum load bearing weight and the required traction weight of the locomotive unit, different transportation modes are selected. The locomotive unit composed of one control vehicle and one motor vehicle is adopted, the axle load of the locomotive is reduced, the axle load and the traction performance of the locomotive are adjusted through the weight of self-loaded goods, flexible and rapid goods transportation is achieved through the management method, and the application range is wide.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

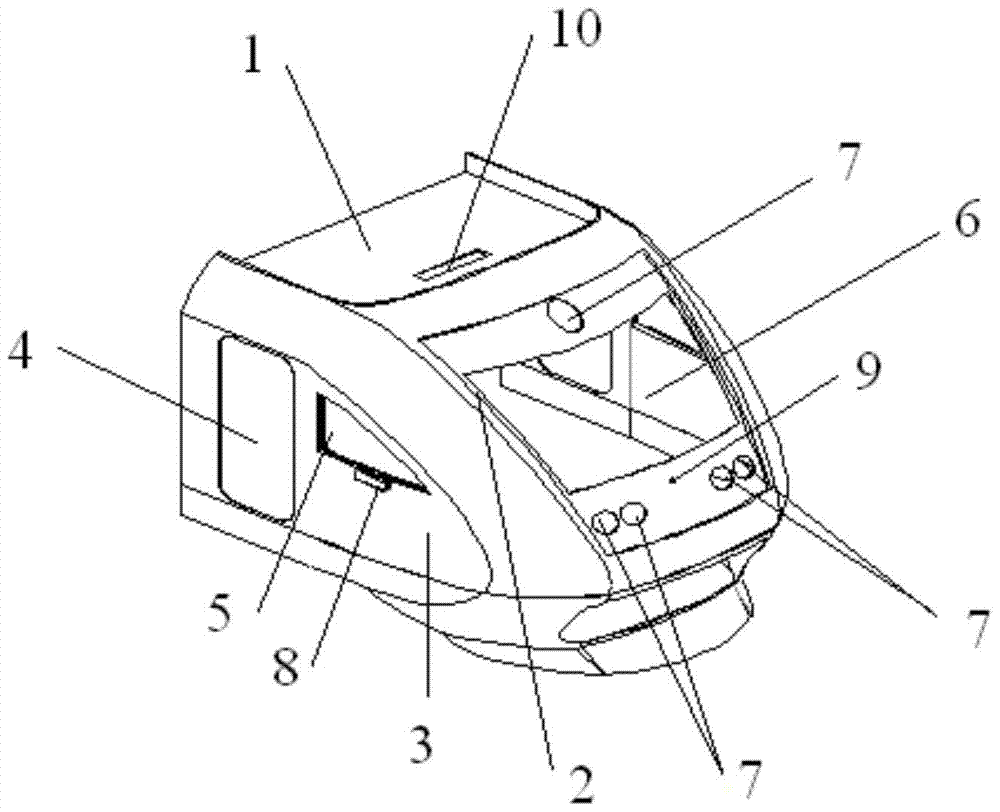

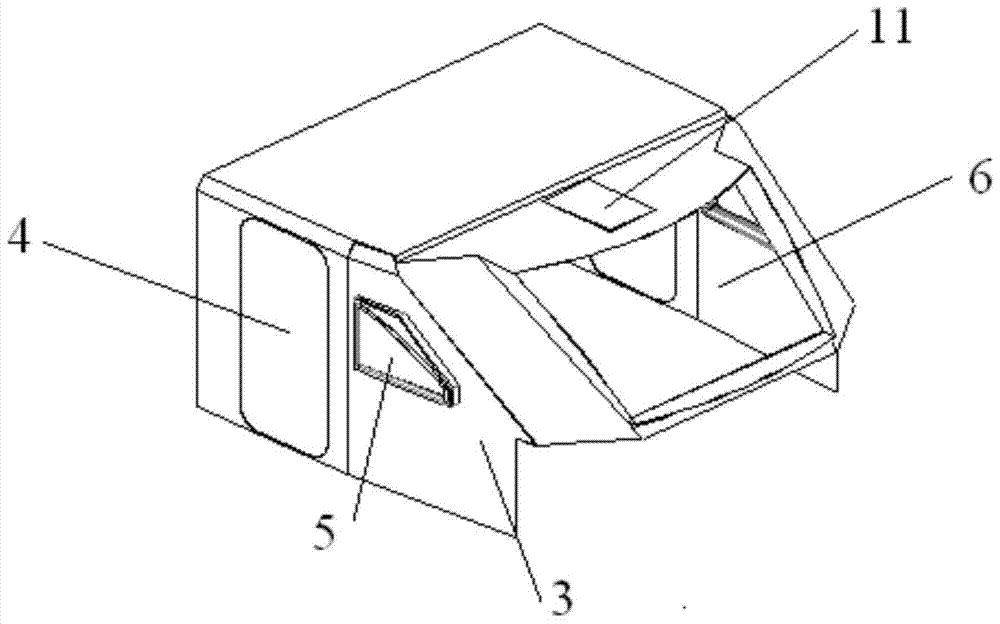

Non-metal overall driver's cab

InactiveCN104512426BReduce weightReduce axle loadAxle-box lubricationLocomotivesMetallic materialsEngineering

The invention provides a nonmetallic whole driver room. The nonmetallic whole driver room comprises a covering, a steel belt skeleton structure and internal decorating plates, wherein the covering is made of nonmetallic materials and is fixed on the steel belt skeleton structure, and the internal decorating plates are embedded in the steel belt skeleton structure. According to the nonmetallic whole driver room provided by the invention, the covering is made of the nonmetallic materials and is fixed on the steel belt skeleton structure, and the internal decorating plates are embedded in the steel belt skeleton structure, so that the whole weight of the driver room is lightened, the axle weight of a locomotive is lightened, and the running speed of the locomotive is increased.

Owner:CRRC BEIJING ERQI LOCOMOTIVE CO LTD

A bidirectional tensioning device with bidirectional association and variable damping device

Owner:NINGBO FENGMAO FAR EAST RUBBER

CR300F electric train set

InactiveCN110871817ASave energyAvoid wear and tearElectrodynamic brake systemsElectric locomotivesRegenerative brakeWorking life

The design speed per hour of the train set is 300 km / h, and the continuous overall trip speed is 270 km / h. The power configuration of the train set is a power dispersing type, eight trains are groupedand are of a six-moving two-dragging type, a power driving manner is adopted, and alternating-current transmission is adopted. Two DSA-350 high-speed pantographs are arranged, and abrasion to an overhead line system can be avoided; and regenerative braking is adopted by the train set, electric energy can be saved, the electric energy is fed back to the overhead line system, braking energy recovery is achieved, and energy is saved. Meanwhile, due to power dispersion of the train set, the axle load can be reduced to the lowest. The design working life is 30 years. The train set is a large-scalehollow profile aluminum alloy train.

Owner:王书晗

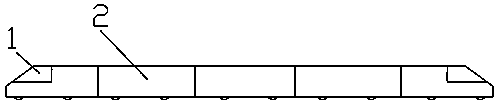

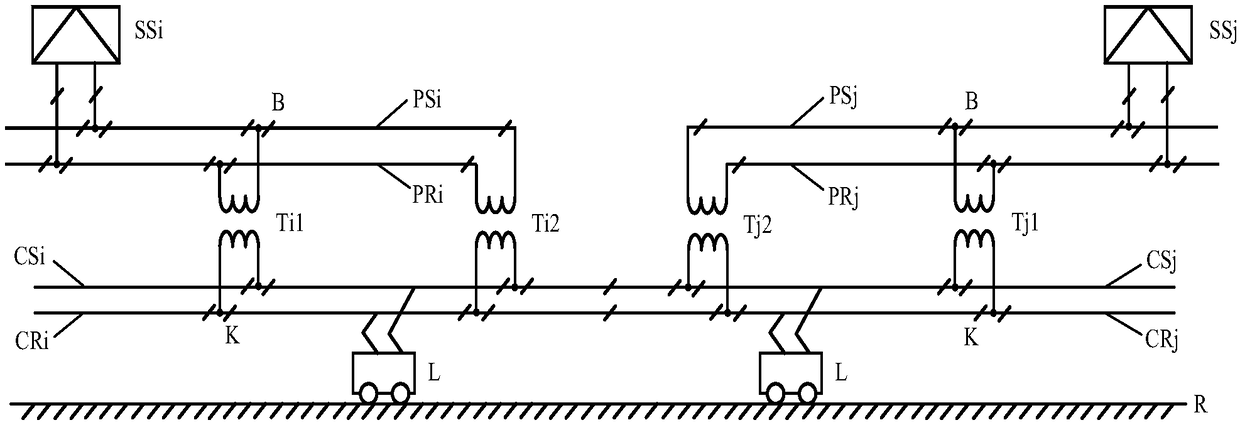

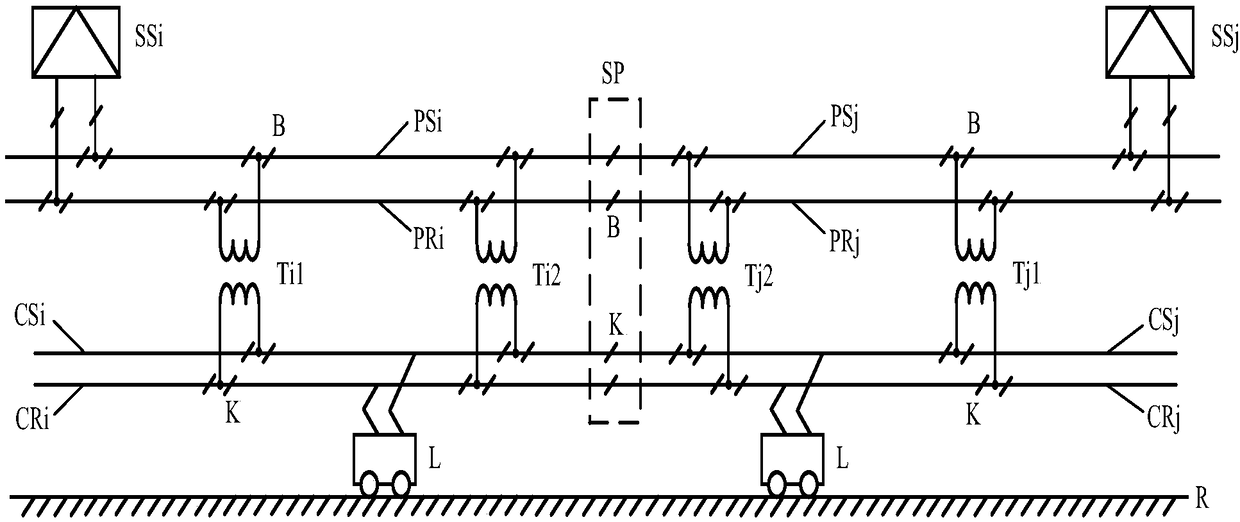

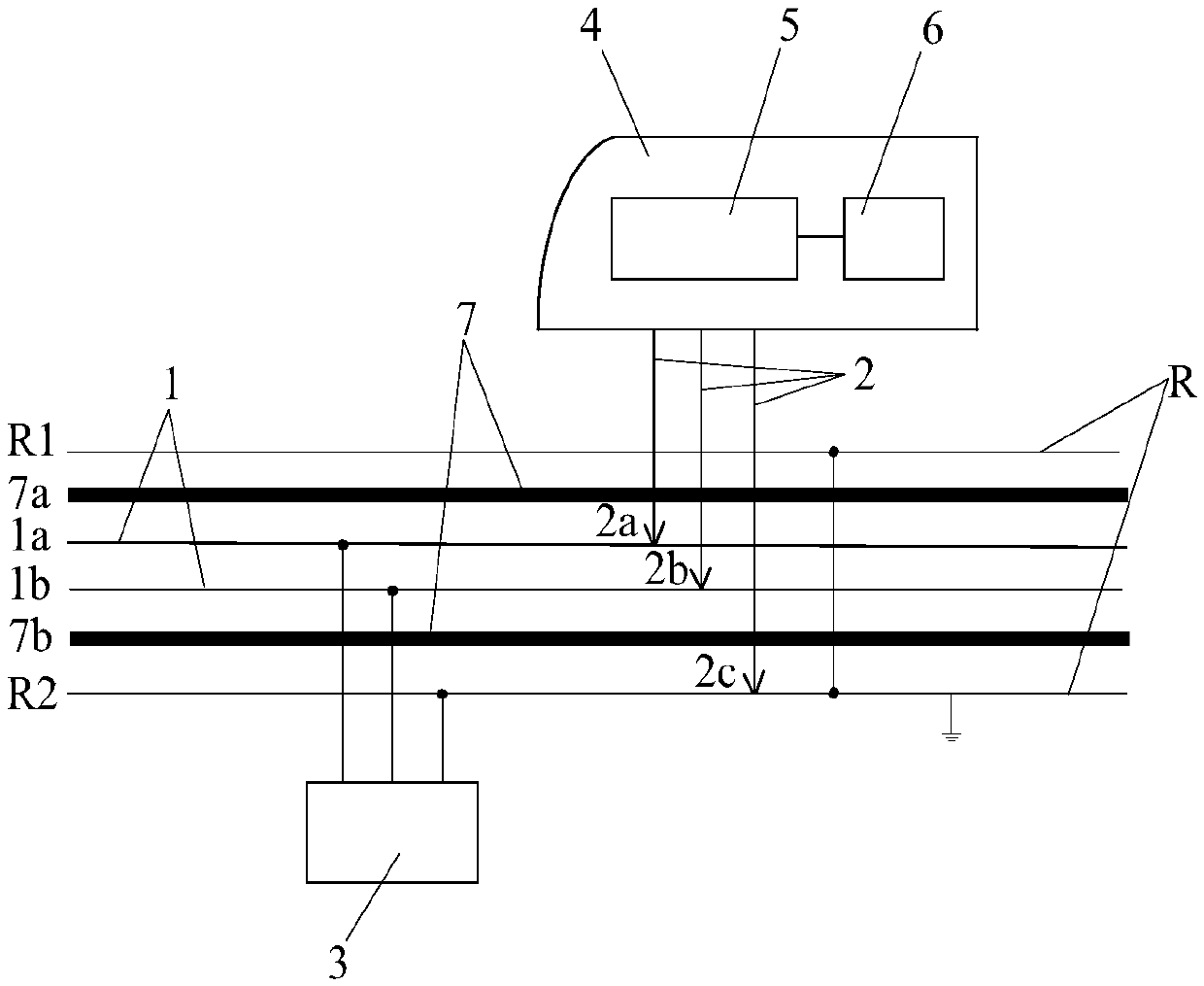

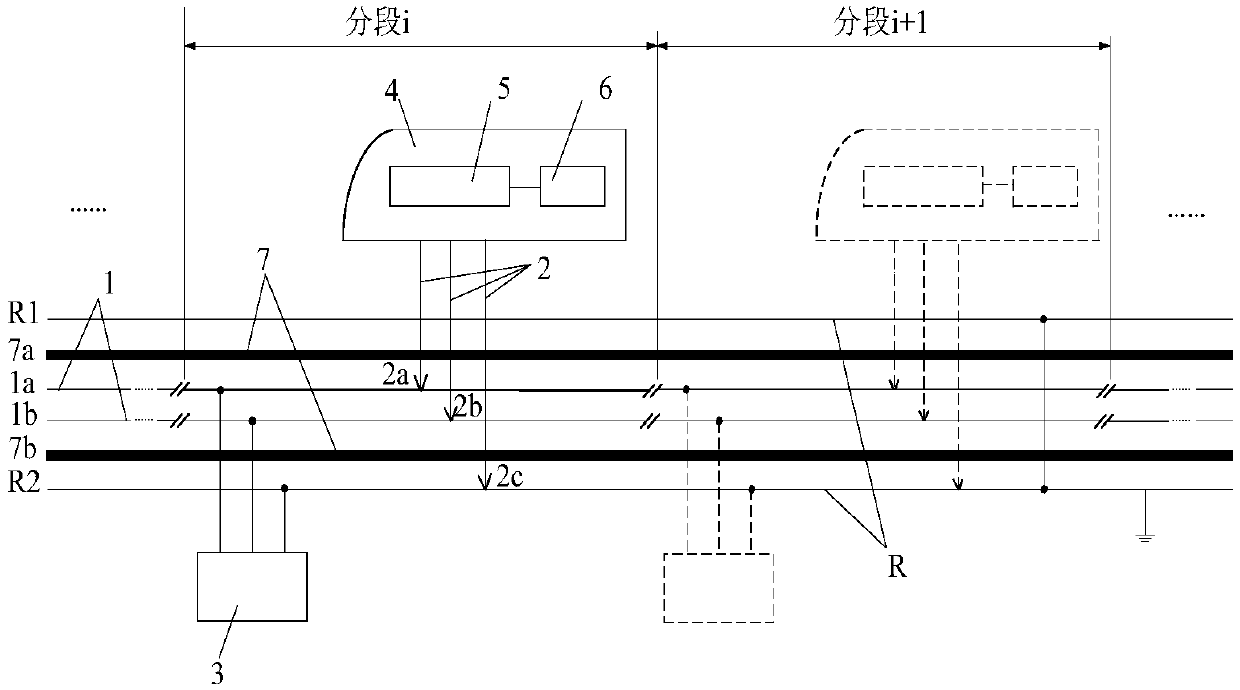

Three-rail power supply control system for electrified railway train

PendingUS20220089033A1Low costImprove economyRailway vehiclesPower railsAutomatic controlPower control system

The present invention relates to the technical field of train power supply and operation control, and provides a three-rail power supply control system for an electrical railway train. Power supply rails in the system are divided into a first power supply rail, a second power supply rail, and a third power supply rail, wherein the first power supply rail, the second power supply rail, and a running rail constitute a three-phase AC power supply loop, and the third power supply rail and the running rail constitute a DC power supply loop. An AC-DC-AC variable voltage variable frequency device supplies power to a train traction motor by means of the three-phase AC power supply loop and current collectors. Frequency modulation and voltage regulation power supply is conducted by means of the AC-DC-AC variable voltage variable frequency device on the ground to achieve train driving and operation control. The DC power supply loop is powered by means of a rectifying device on the ground, and power is supplied to auxiliary electric equipment of the train by means of the current collectors. By changing the power supply mode of the system and optimizing the system structure, the weight and axle load of train-mounted equipment are effectively reduced, lightweight of the train is achieved, and the bearing efficiency of the train is improved, and moreover, automatic control and unmanned driving for train operation are achieved in the most economical way.

Owner:SOUTHWEST JIAOTONG UNIV

Railway turnout tamping wagon

The invention discloses a railway turnout tamping wagon, which relates to the technical field of track detection and comprises a main frame and a wagon body, a front bogie is arranged at the front endof the main frame, and the front bogie is provided with a first shaft and a second shaft which are arranged front and back; a rear bogie is arranged at the rear end of the main frame and provided with a third shaft and a fourth shaft which are arranged front and back. A B-point detection trolley is arranged on the rear side of the rear bogie, a C-point detection trolley is arranged between the rear bogie and the front bogie, and a D-point detection trolley is arranged on the front side of the front bogie. The third shaft is optical polished shaft, and the fourth shaft is provided with an axlegearbox.

Owner:GEMAC ENG MACHINERY

An electrified railway connecting power supply structure

ActiveCN106218448BImprove connectivityFacilitate mobile launchPower supply linesAc network circuit arrangementsOvervoltagePower grid

The invention discloses a connected power supply structure for an electrified railway, and relates to the technical field of rail transit AC traction power supply. For more than two main substations, the primary side is connected to the same power grid, and the secondary side feeds out the medium-voltage power supply line and the medium-voltage return line; the medium-voltage power supply line and the medium-voltage return line are connected to the Contact power supply lines and contact return lines; medium-voltage power supply lines and medium-voltage return lines, contact power supply lines and contact return lines are all segmented at the step-down transformer; contact power supply lines and contact return lines within the scope of each main substation The voltage phase between the contact return lines is the same; the contact power supply line and the contact return line supply power to the train; under normal circumstances, the medium voltage supply lines and the medium voltage return lines of two adjacent main substations are mutually Not connected, but the adjacent contact power supply lines are connected, and the contact return lines are connected to realize continuous power supply of the train; the middle point of the primary winding of the step-down transformer is pulled out to ground, which can suppress the system overvoltage. Mainly used for rail transit power supply.

Owner:SOUTHWEST JIAOTONG UNIV +1

A kind of titanium alloy and its application in processing train connecting parts

The titanium alloy disclosed by the invention comprises the following components by weight percentage: 3.8-4.8% of Al, 2.0-3.2% of V, 0.7-1.7% of Fe, 0.2-0.3% of O, and the balance is Ti. The processing steps are as follows: Step 1) The titanium alloy ingot is heated in the temperature range of 100-150°C above the phase transition point, and the final forging temperature is 900°C±20°C, and the billet forging is carried out, and the reduction is 10-25mm each time. Between; Step 2) Heating within the temperature range of the phase transition point ± 20°C, performing upsetting and drawing forging, the final forging temperature is 850°C ± 20°C, and the reduction does not exceed 30% of the length; Step 3) In the phase Heat at 30-50°C below the change point, and then forge the finished product. The deformation is controlled at about 60%, and the finished product is heat-treated after forging. Step 4) The heat treatment system is vacuum annealing, the annealing temperature is about 150° C. within the phase transition point, heat preservation for 60-90 minutes, and air cooling. Manufacture transmission pins, connecting rods, motor suspenders, tie rod bodies and fasteners of train or motor car bogies. The invention has the effects of weight reduction and corrosion resistance.

Owner:沈阳泰恒通用技术有限公司

Short stator train three-phase power supply control system

ActiveCN109532570AAchieve lightweightImprove bearing efficiencyPower railsElectric energy managementElectricityControl system

The invention discloses a short stator train three-phase power supply control system and relates to the technical field of train power supply and operation control. The system comprises an AC-DC-AC variable-frequency variable-voltage device, power supply rails, a sensing board, a traveling rail, a vehicle-mounted current collector, a vehicle-mounted three-phase driving winding and a vehicle-mounted rectifying and energy storage device, wherein the AC-DC-AC variable-frequency variable-voltage device, the power supply rails, the sensing board and the traveling rail are arranged on the ground; the vehicle-mounted current collector, the vehicle-mounted three-phase driving winding and the vehicle-mounted rectifying and energy storage device are arranged on a train; the power supply rails include the first power supply rail and the second power supply rail, and the power supply rails and the grounded traveling rail form a three-phase alternating-current power supply circuit; the sensing board and the three-phase driving winding of the train conduct sensing work; the AC-DC-AC variable-frequency variable-voltage device supplies power to the vehicle-mounted three-phase driving winding of the train through the three-phase alternating-current power supply circuit and the current collector; the AC-DC-AC variable-frequency variable-voltage device on the ground is used for frequency adjustment, voltage adjustment and power supply to achieve three-phase drive and operation control over the train; the vehicle-mounted rectifying and energy storage device supplies power to train auxiliary electricity utilization equipment.

Owner:SOUTHWEST JIAOTONG UNIV

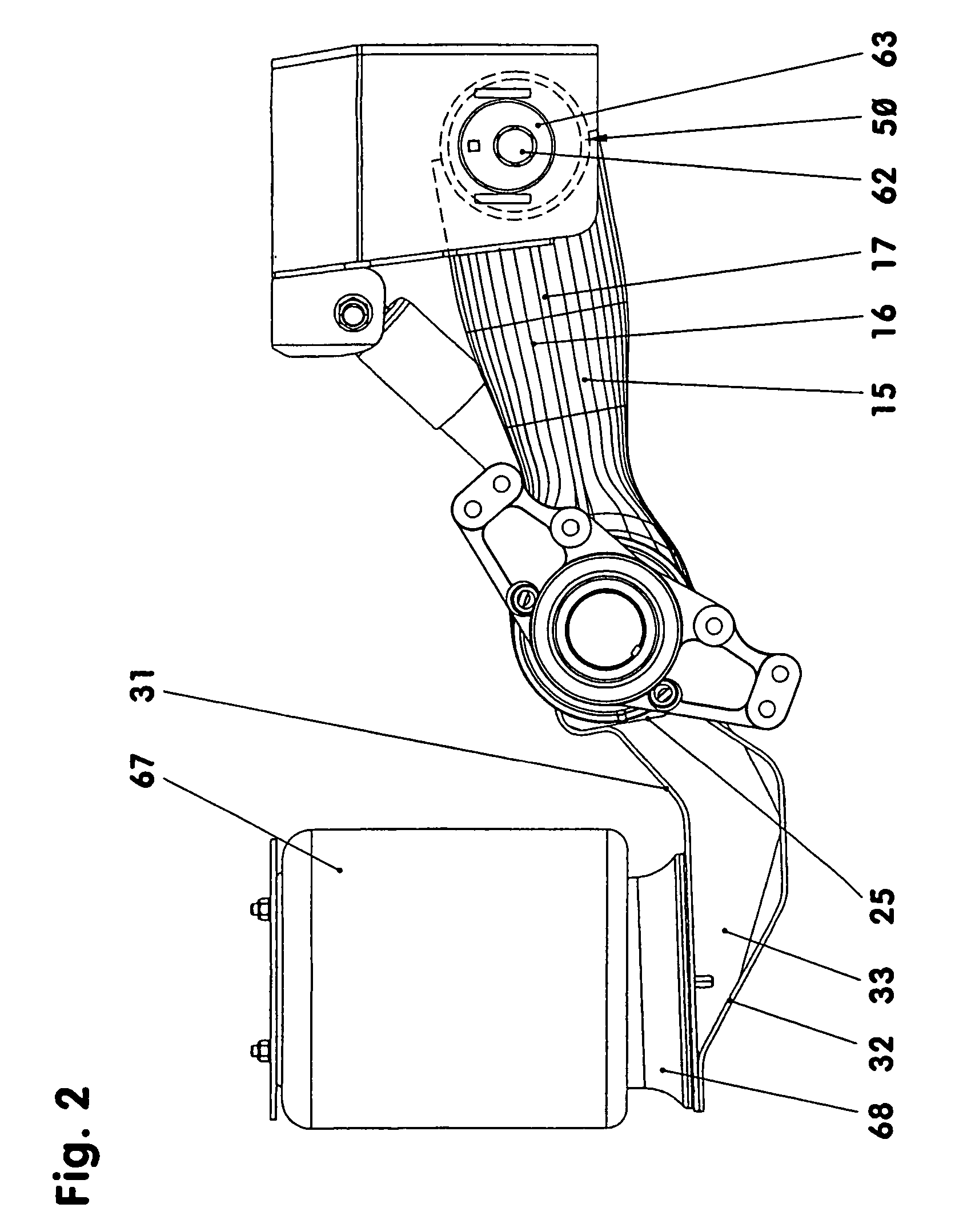

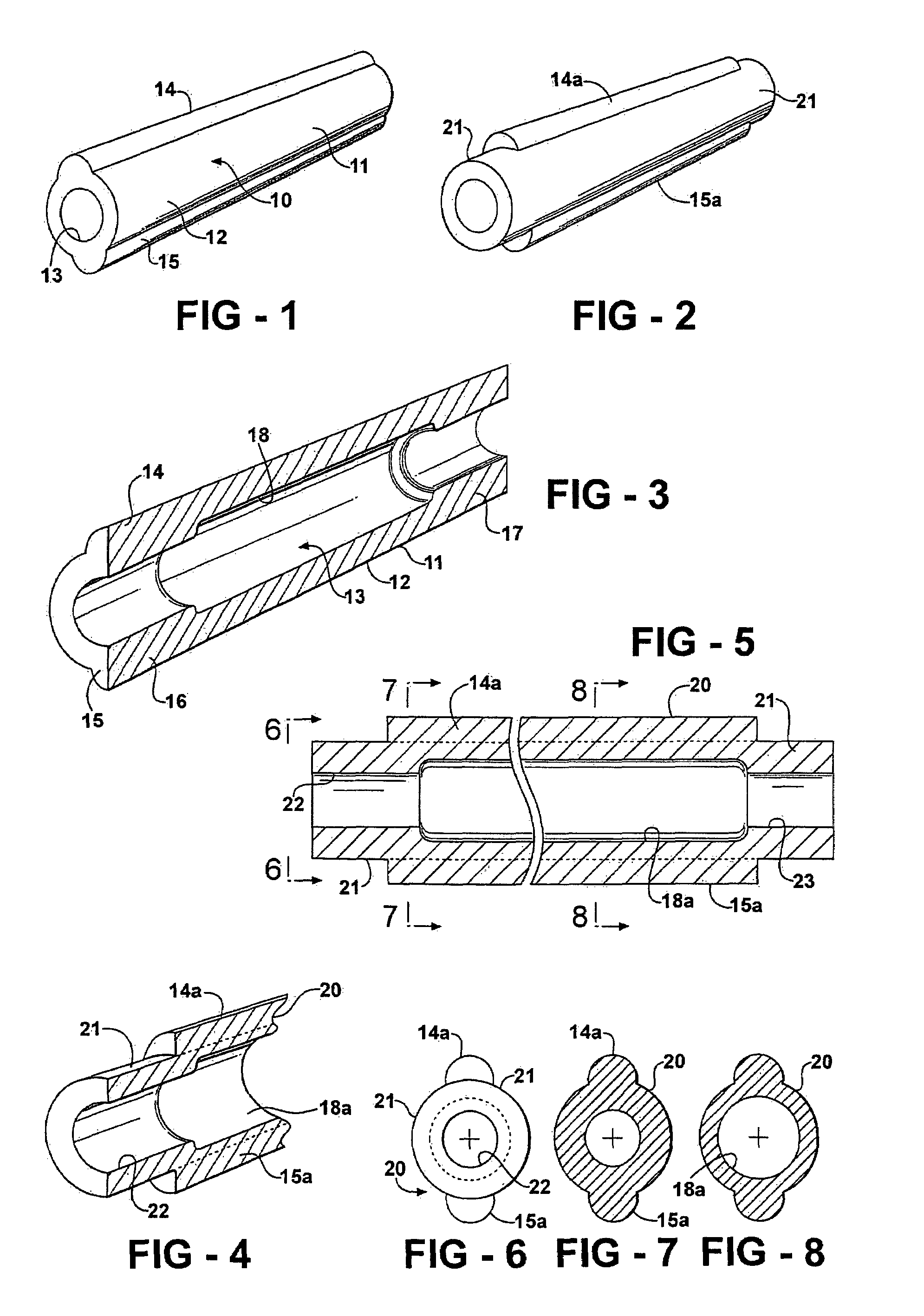

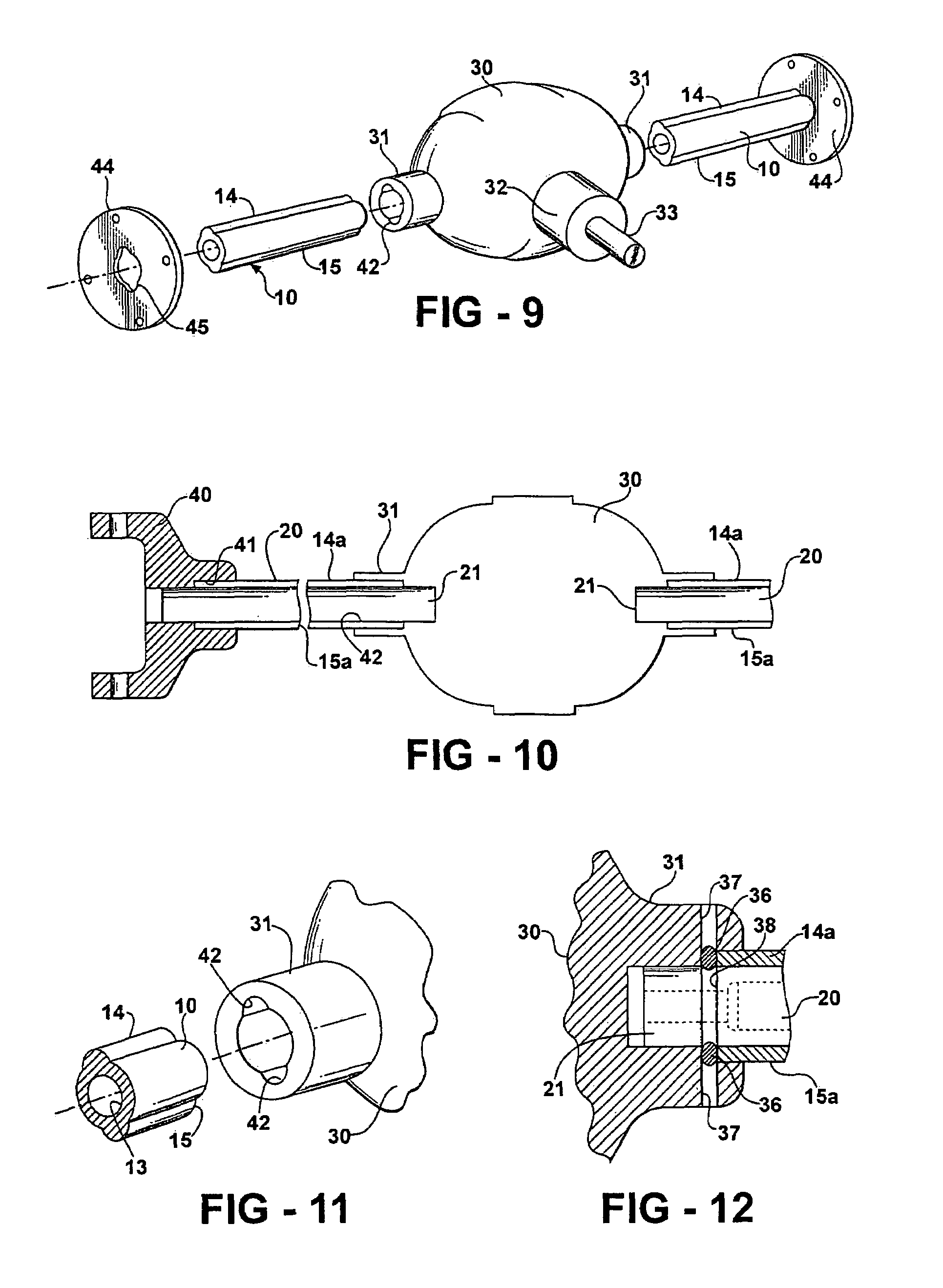

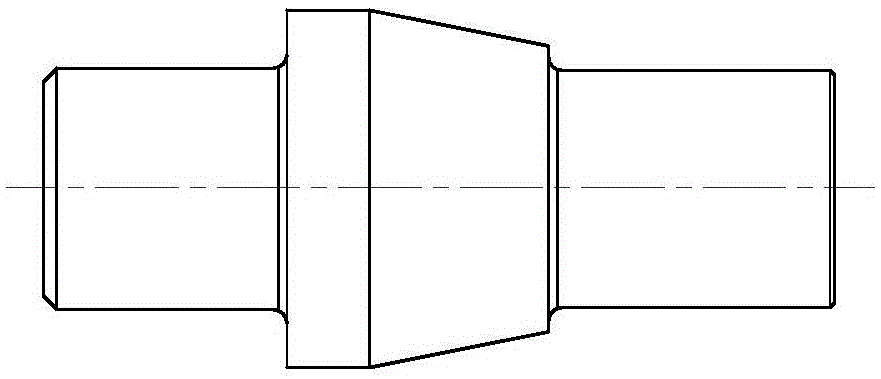

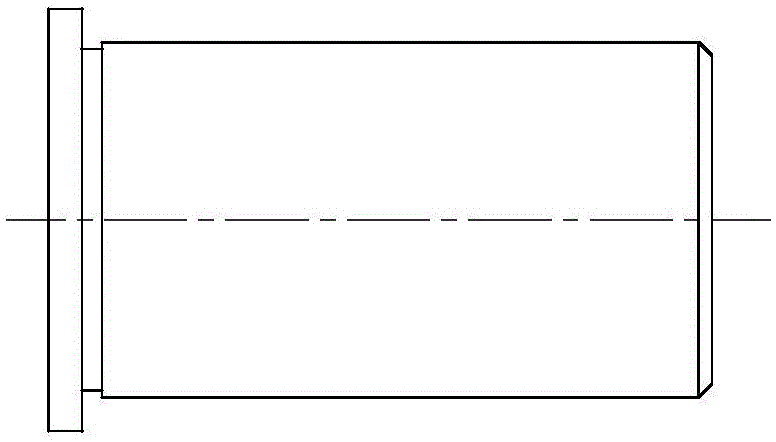

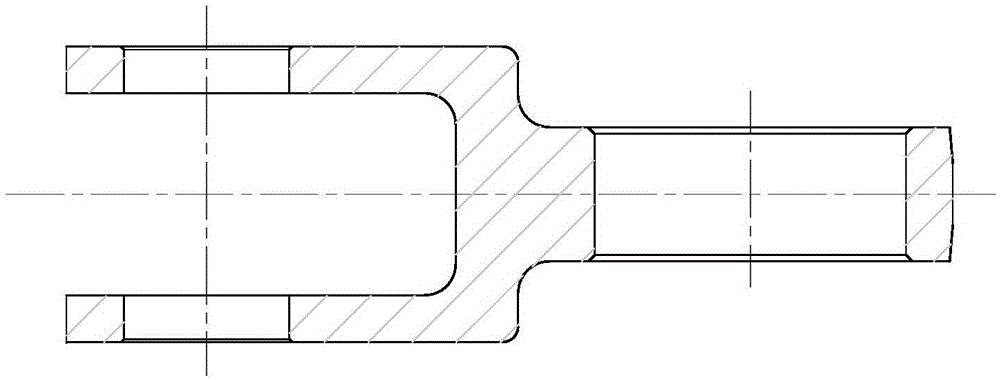

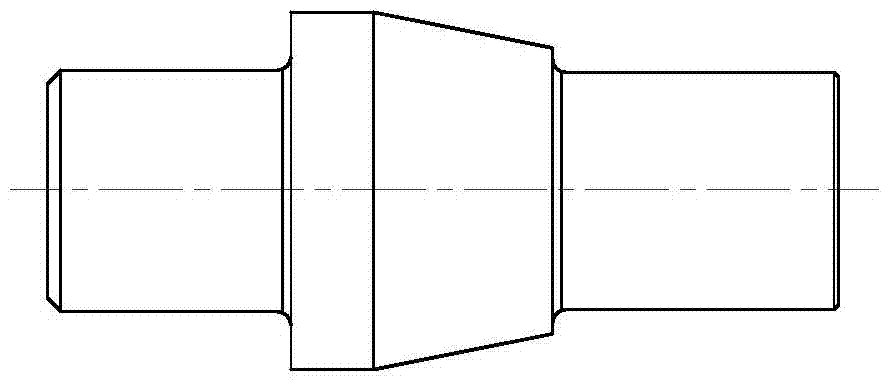

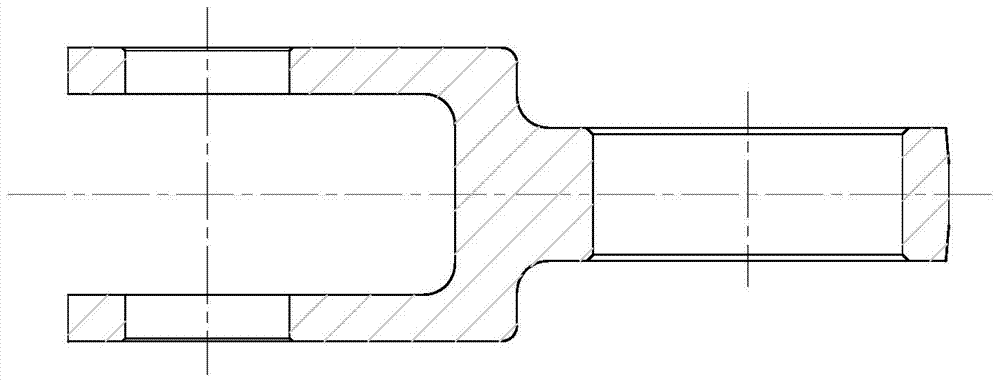

Axle unit

ActiveUS10207556B2Reduce axle loadReduce productionBraking membersWheel manufactureStub axleEngineering

The present invention concerns an axle unit comprising a stub axle and an axle tube, wherein the stub axle has a longitudinal channel which extends inside the stub axle substantially along a stub axis, wherein the stub axle has a transverse channel which extends inside the stub axle substantially transversely to the stub axis and opens to the environment at the outer face of the stub axle, wherein the longitudinal channel and the transverse channel are connected together, wherein the stub axle has a stub joining region to which the hollow-bodied axle tube can be secured.

Owner:SAF HOLLAND GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com