An electrified railway connecting power supply structure

A technology for electrified railways and structures, applied in the direction of power lines, circuit devices, electrical components, etc., can solve the problems that the impedance value of series reactors cannot be too large, occupy valuable space on trains, and affect system reliability, etc., to eliminate defects impact, reduce the risk of electric shock to personnel, and be easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

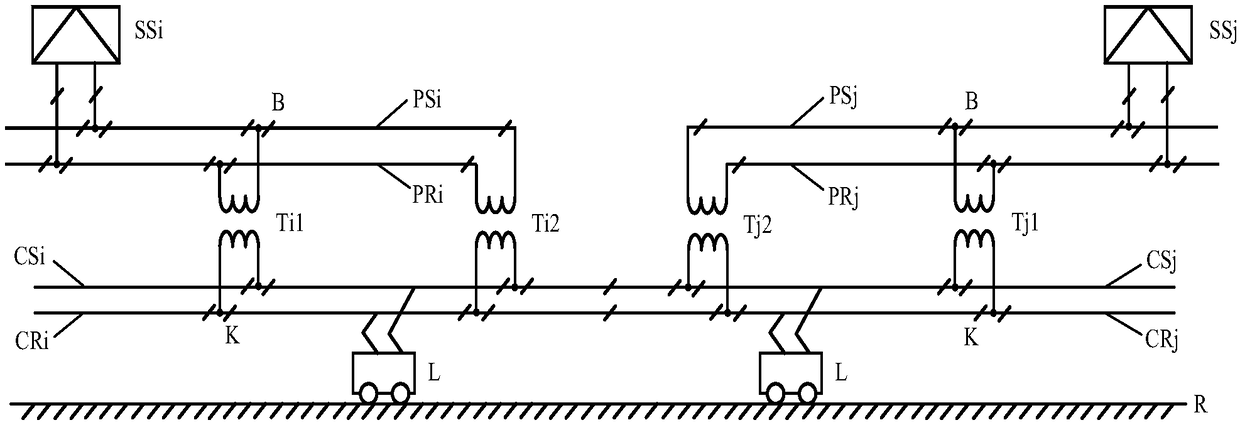

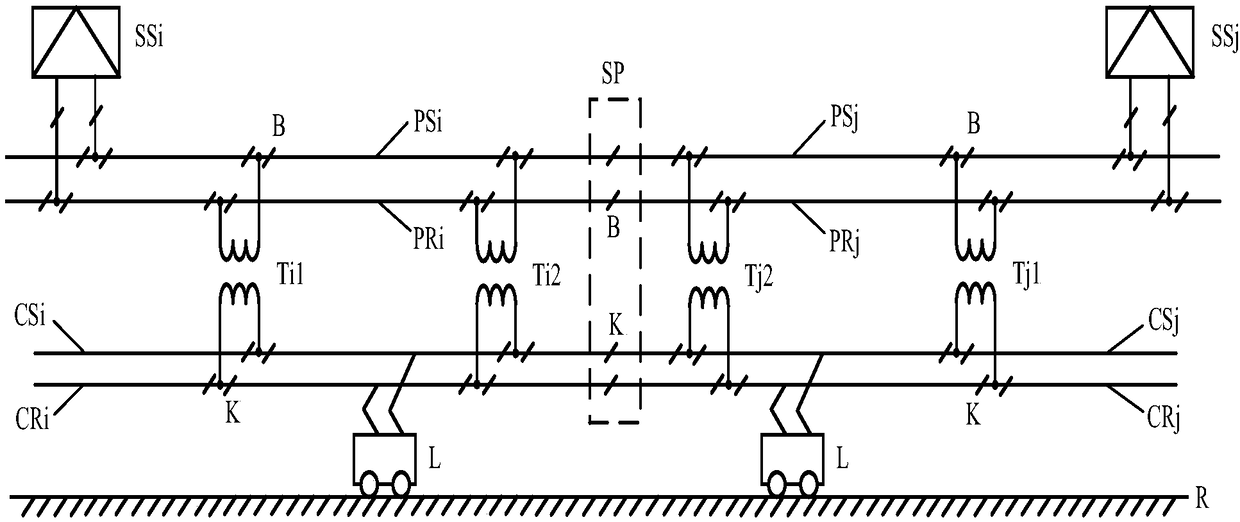

[0020] Example: such as figure 1 As shown, a schematic diagram of the connected power supply structure of an electrified railway. The electrified railway traction power supply system includes two or more main substations. The primary side of the main substations is connected to the same power grid. Note that the two adjacent main substations are the main substation SSi and the main substation SSj, the secondary side of the main substation SSi feeds out the medium-voltage power supply line PSi and the medium-voltage return line PRi, and the medium-voltage power supply line PSi and the medium-voltage return line PRi are connected to the contact power supply line through the step-down transformers Ti1 and Ti2 along the line CSi and contact return line CRi, that is, the two primary terminals of the step-down transformers Ti1 and Ti2 are respectively connected to the medium voltage supply line PSi and the medium voltage return line PRi, and the two terminals of the secondary side a...

example 1

[0028] Example 1: Suppose the voltage of the incoming line grid of the traction substation is 110kV, the traction grid adopts 27.5kV direct supply mode, and the transformation ratio n=110 / 27.5=4, then the balance current (shunt) of the traction grid and the 110kV transmission line in parallel is 1 / 16, if the low-voltage circuit of contacting the power supply line and the contacting return line is added, and its voltage is selected as 5.5kV, then the transformation ratio m=27.5 / 5.5=5, then the balanced current of the low-voltage circuit and the 110kV transmission line in parallel (shunt ) is 1 / (nm) 2 =1 / 4002 = 25 times.

example 2

[0029] Example 2: Suppose the voltage of the incoming power grid of the traction substation is 220kV, the traction network adopts the 27.5kV direct supply mode, and the transformation ratio n=220 / 27.5=8, then the balanced current (shunt) of the traction network and the 220kV transmission line in parallel is 1 / 64, if you add the low-voltage circuit of contacting the power supply line and the contacting return line, and select its voltage as 5.5kV, then the transformation ratio m=27.5 / 5.5=5, then the balanced current of the low-voltage circuit and the 220kV transmission line in parallel (shunt ) is 1 / (nm) 2 =1 / 16002 = 25 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com