A bidirectional tensioning device with bidirectional association and variable damping device

A technology of tensioning device and damping device, which is applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of increasing the variation of the belt on the tight side, the tension of the belt on the tight side is large, and the life is short. The effect of excessive load, faster swing speed and longer service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

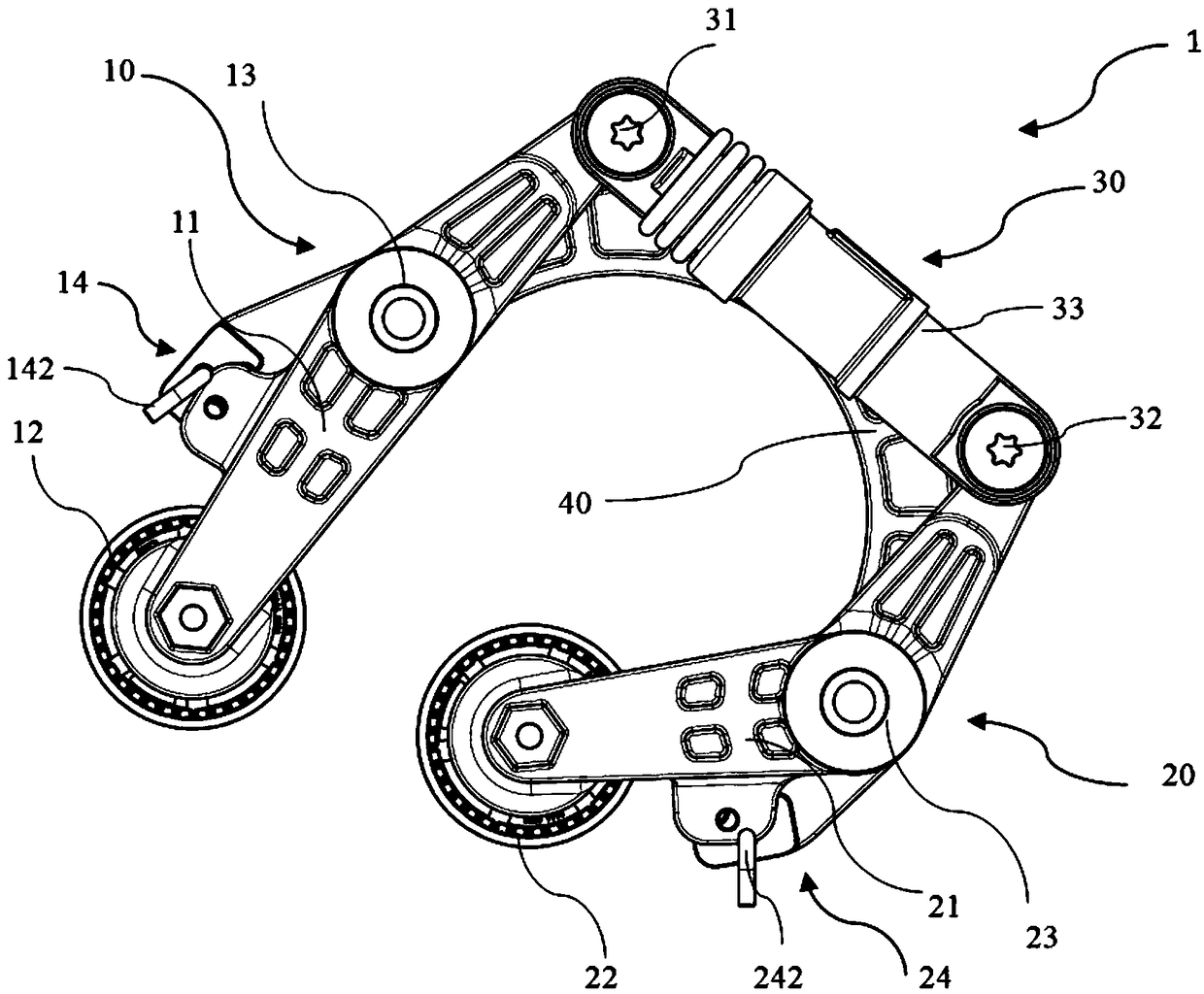

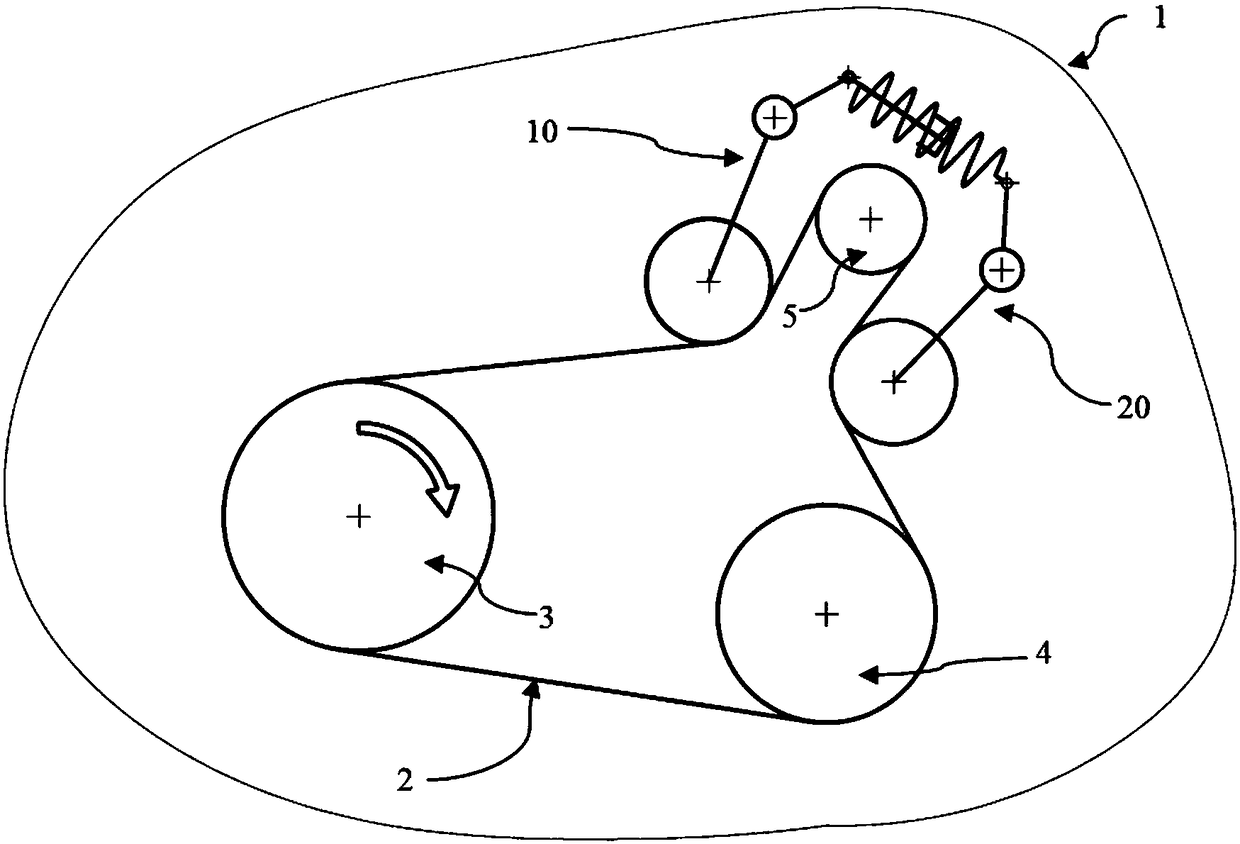

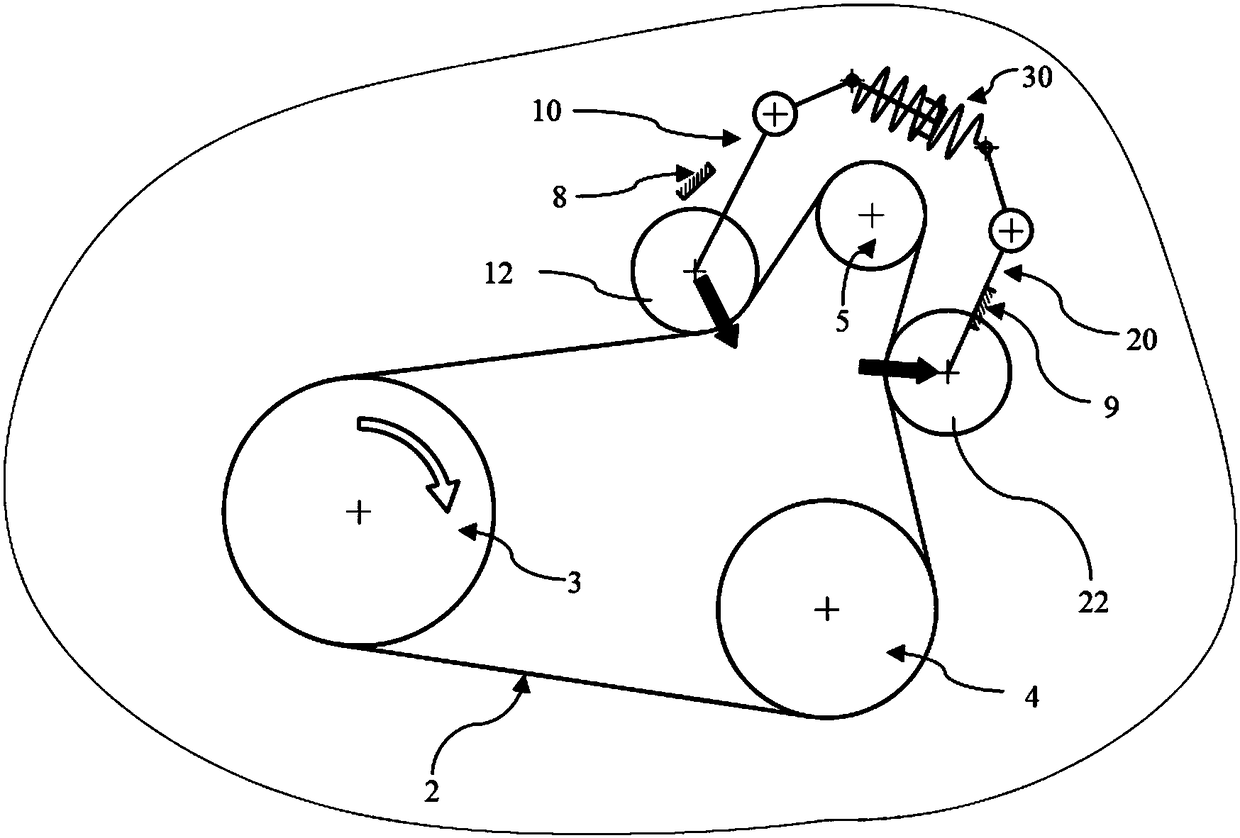

[0049] figure 1 , Figure 5 A two-way tensioning device 1 is shown, the two-way tensioning device 1 includes a first tensioner 10, a second tensioner 20, an associated variable damping device 30 and a base 40, the The first tensioner 10 and the second tensioner 20 are respectively fixed on the base 40 , and can swing around their respective first rotating shaft 15 and second rotating shaft 16 . One end of the first tensioner 10 and one end of the second tensioner 20 are respectively connected to the associated belt variable damping device 30 by fastening components 19 and 29, and each hinge can rotate around its own Centers 27 and 28 swing freely (see Figure 8 ), so that the first tensioner 10 and the second tensioner 20 are associated.

[0050] The first tensioner 10 includes a first tensioning arm 11, a first tensioning wheel 12 and a first damping device 13, the first tensioning wheel 12 is rotatably fixed to the first sheet One end of the tensioning arm 11, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com