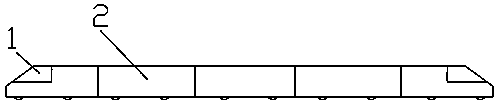

CR300F electric train set

A 1. CR300F, EMU technology, applied in the direction of electric vehicles, electric locomotives, electric braking systems, etc., to achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The design speed of the EMU is 300km / h, and the continuous operating speed is 270km / h. The power configuration of the EMU is power distributed, with 8 marshallings in the form of 6 moving and 2 dragging. The driving mode is electric, and it adopts AC drive. Two sets of DSA-350 high-speed pantographs can avoid the wear of the catenary. The vehicle adopts regenerative braking, which can save electric energy and feed back the electric energy to the catenary to realize the recovery of braking energy and save energy. At the same time, the vehicle's power distribution can minimize the axle load. The design service life is 30 years. The car body type is a large hollow profile aluminum alloy car body

[0013] Cars 1 and 8 of this car are first-class cars, and cars 2 to 7 are second-class cars. Among them, car No. 5 is a second-class car / dining car. Cars No. 1 and No. 8 are unpowered cars (trailers), and Cars No. 2 to No. 7 are powered cars (powered cars). The train is equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com