Bottom-arranged power integrated system for high-speed internal combustion motor train unit

An integrated system and EMU technology, which is applied in the field of power integration systems arranged under high-speed internal combustion EMUs, can solve the problems of large space occupation, disadvantages, and low integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

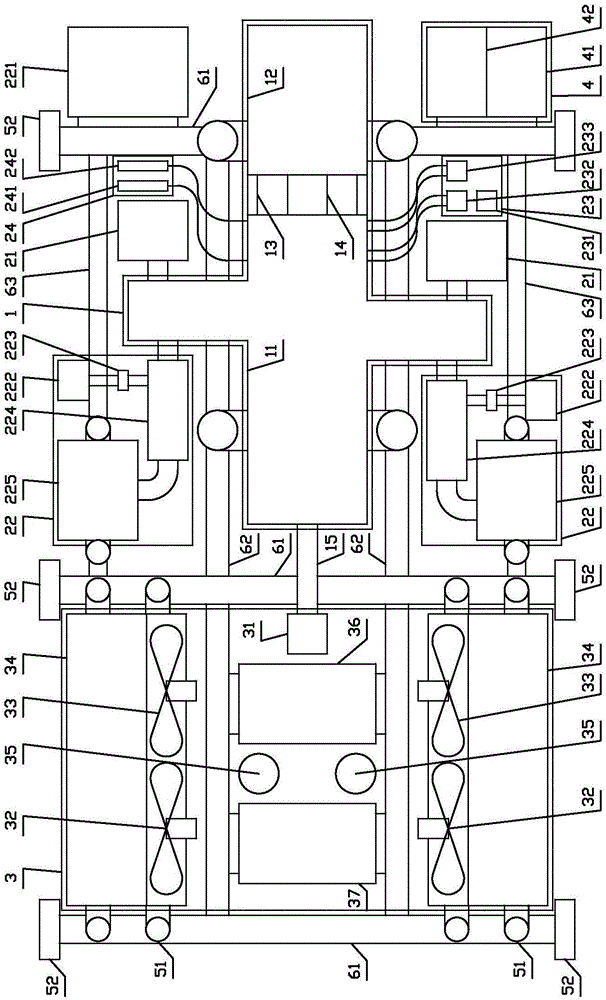

[0017] Such as figure 1 As shown, a high-speed internal-combustion EMU under-car layout power integration system includes a diesel generator set 1, a diesel engine auxiliary system 2, a cooling system 3, an electronic control system 4 and an installation frame 6; the diesel generator set 1 includes a diesel engine 11 And the generator 12 fixed with the diesel engine 11 through the connection flange, the diesel engine flywheel and the generator shaft are connected together through the first elastic coupling 14, the rated power of the diesel engine 11 described in this embodiment is 588-735kW, ensuring that the motor vehicle The group operates at a high speed of 160-200km / h, and adopts a 12-cylinder V-shaped arrangement at an angle of 90° to minimize the height and meet the layout requirements under the vehicle floor; the diesel engine auxiliary system 2 includes two side intake air filter 21, exhaust SCR after-treatment system 22, fuel system 23 and engine oil system 24, the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com