A kind of titanium alloy and its application in processing train connecting parts

A technology of titanium alloy and processing steps, which is applied in the field of titanium alloy connectors of trains, can solve the problems of complex heat treatment process, increase the workload of workers, accelerate the corrosion of steel parts, etc., achieve strong corrosion resistance, reduce maintenance costs, and prolong service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

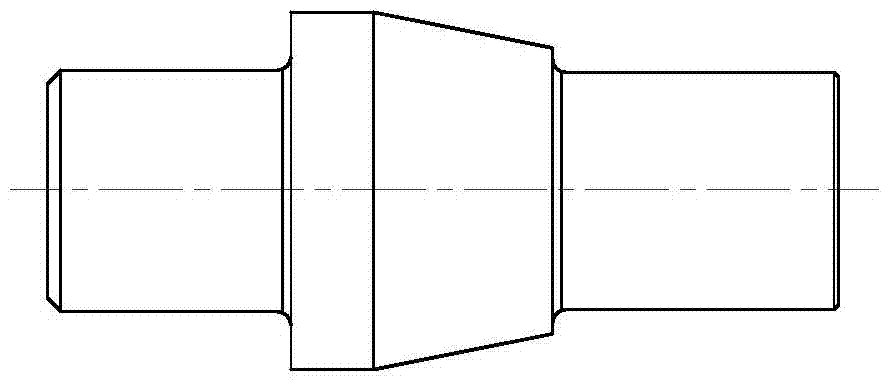

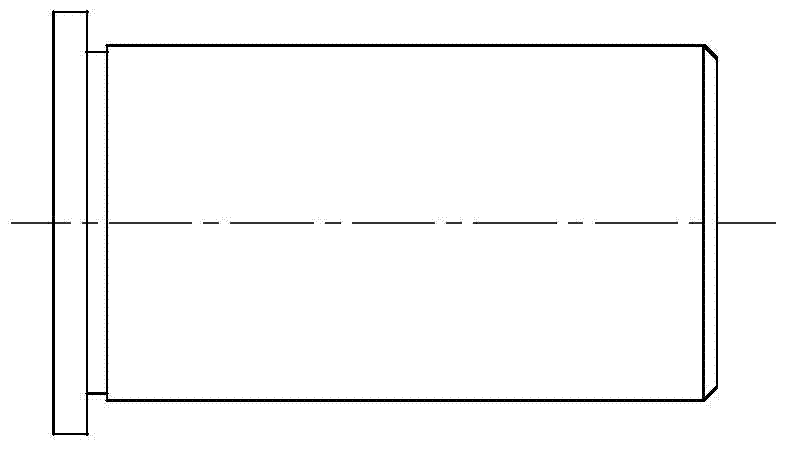

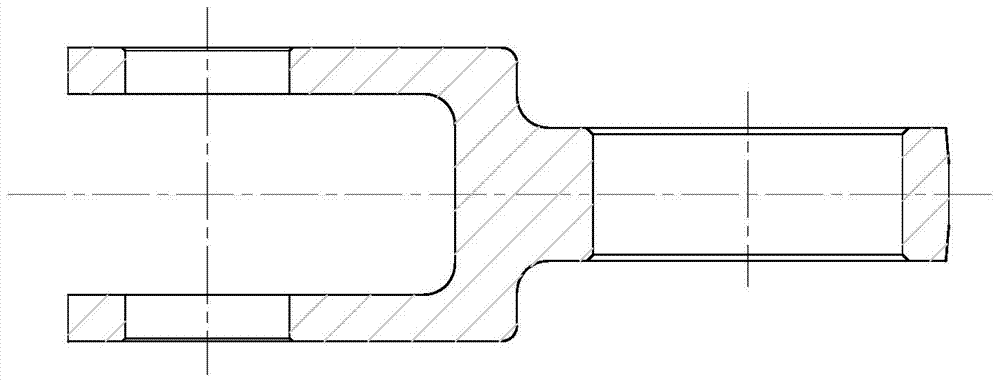

Image

Examples

Embodiment 1

[0039] Embodiment 1: The composition of the titanium alloy of the present invention is as follows: Al 4%, V 3.1%, Fe 1.4%, O 0.3%, Ti91.2%.

Embodiment 2

[0040] Embodiment 2: The composition of the titanium alloy of the present invention is as follows: Al 4.5%, V 2.1%, Fe 0.9%, O 0.3%, Ti92.2%.

Embodiment 3

[0041] Embodiment 3: The composition of the titanium alloy of the present invention is as follows: Al 4.8%, V 2.6%, Fe 1%, O 0.3%, Ti91.3%.

[0042] The processing method of titanium alloy is as follows:

[0043] Preparation of titanium sponge → melting ingot → billet forging → grinding → upsetting forging → grinding → finished product forging → annealing → lathe polishing → bar.

[0044] Preparation of titanium sponge: Titanium sponge is formed by chlorination of rutile ore to form TiCl 4 , and then reduce TiCl with Mg 4 And obtained sponge titanium. Sponge titanium is divided into different grades such as grade 0, grade 1 and grade 2 according to the content of impurities, wherein grade 0 sponge titanium has the lowest impurity content, and titanium alloy of the present invention adopts grade 1 sponge titanium.

[0045] Melting ingot: Titanium is an active metal, which is very easy to react with oxygen, nitrogen and other gases at high temperature, and also reacts with al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com