Steel rail for subways and preparation method of steel rail

A technology for steel rails and subways, applied in the field of subway steel rails and their preparation, can solve the problems of increasing the labor intensity of maintenance personnel, the frequency of steel rail replacement, the contact fatigue damage of hot-rolled steel rails, and the increase of line maintenance costs, and achieve excellent resistance to contact fatigue. The effect of damage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] According to the second aspect of the present invention, the present invention also provides a method for preparing the above-mentioned steel rail for subway, which includes the following steps: rolling the steel slab after the heat preservation treatment to obtain the waste heat rail, and developing the rail head portion of the rail with waste heat Accelerated cooling heat treatment, accelerated cooling heat treatment is divided into two stages: the first stage, the cooling temperature is greater than 800 ℃, the cooling rate is controlled at 4-5 ℃ / s for cooling; the second stage, when the rail is cooled to 550-600 ℃, the control Continue cooling at a cooling rate of 1.5-2.5°C / s; stop accelerated cooling when the temperature drops to 440-460°C, and then cool naturally in the air to room temperature.

[0023] According to the method of the present invention, based on the weight of the steel slab, it contains 0.65-0.75% by weight of C, 0.20-0.50% by weight of Si, 0.80-1.00...

Embodiment

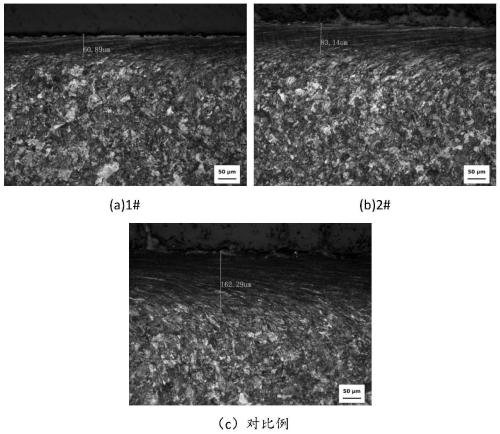

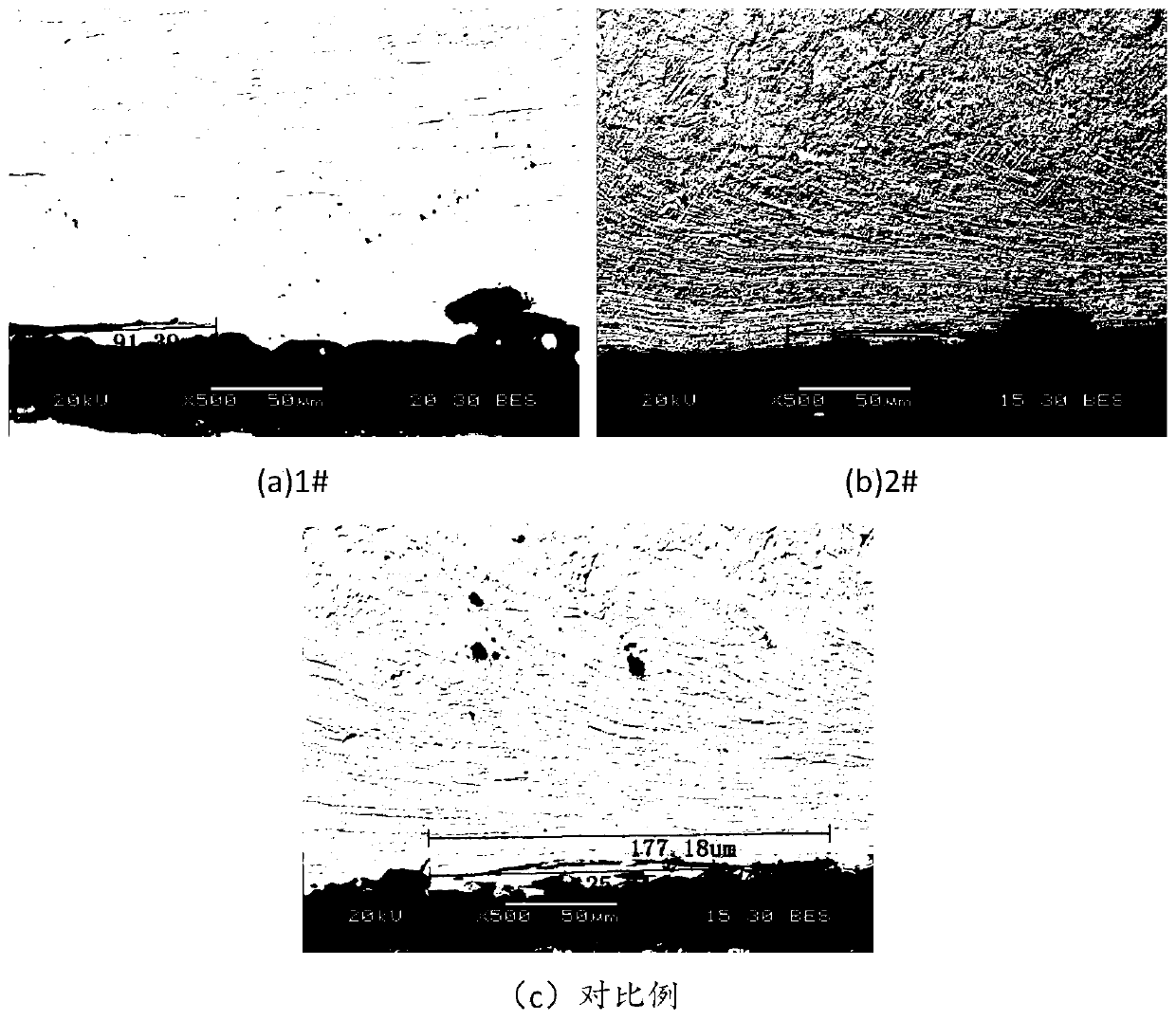

[0031] Two steel rails were rolled out by adopting a kind of steel rail for subway with good contact fatigue performance of the present invention and its preparation method to carry out relevant component performance inspection, and the results are as follows:

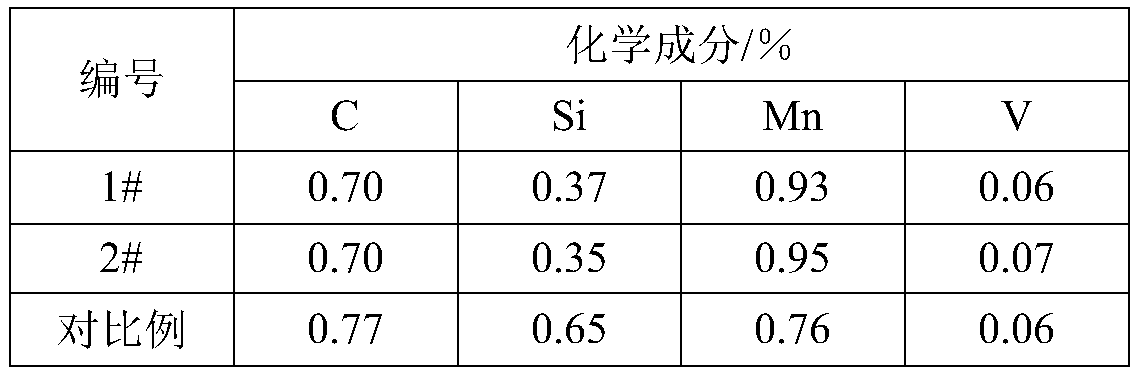

[0032] Table 1 shows the chemical composition of the two steel rail embodiments rolled according to the composition scope of the present invention and the chemical composition of the conventional steel rail comparative example of the current line.

[0033] Table 1 two embodiment of the present invention and comparative example chemical composition

[0034]

[0035] The steel billet containing the above components is rolled into 60kg / m rails, and the heat treatment process of the two rails is shown in Table 2.

[0036] Table 2 heat treatment process control parameters

[0037]

[0038] The rails treated by the above process are cooled to room temperature, and the contact fatigue samples are taken from the upper rai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com