Three-phase motor train unit traction transmission power supply system

A traction drive and power supply system technology, which is used in the traction of AC induction motors, motor vehicles, electric vehicles, etc., can solve the problems of large size and weight of on-board traction transformers, increasing the axle load of locomotives or EMUs, and restricting the speed of EMUs. , to achieve the effect of light weight, reduce axle load, and isolate voltage fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

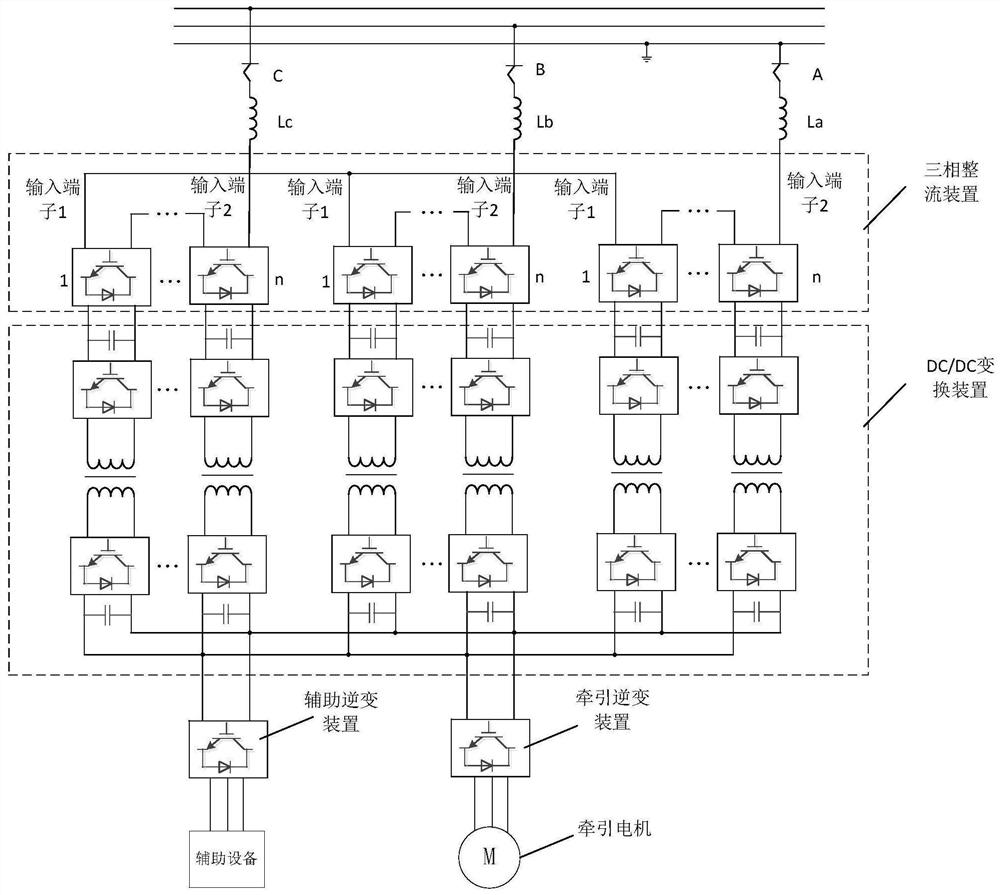

[0027] Such as figure 1 As shown, this embodiment provides a three-phase EMU traction drive power supply system, including:

[0028] A three-phase rectifier, including three-phase AC input ports and three sets of DC output port groups, each set of DC output port groups includes n DC output ports, where n≥1;

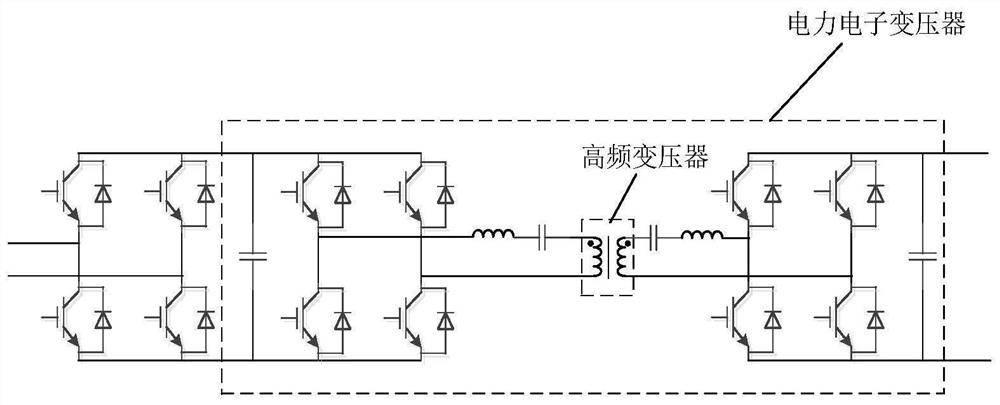

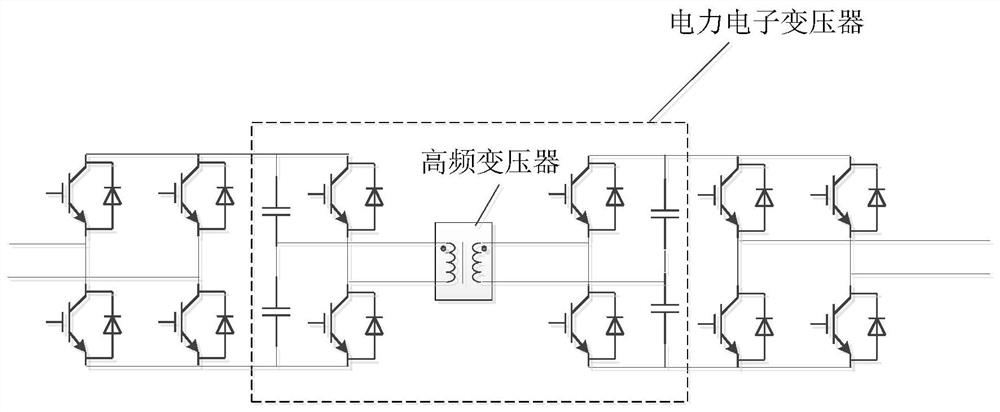

[0029] The DC / DC conversion device includes 3n independent power electronic transformers, the input port of each power electronic transformer is correspondingly connected to a DC output port of the three-phase rectification device, and the output port of each power electronic transformer is connected in parallel as the DC The DC output port of the / DC conversion device;

[0030] A traction inverter device, the input port of the traction inverter device is connected to the DC output port of the DC / DC conversion device, and the output port of the traction inverter device is electrically connected to the traction motor.

[0031] Here, the 3n independent power electronic tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com