Permanent magnet eddy current speed controller based on conjugated magnetic feed rotor

A magnetic rotor and eddy current technology, which is applied in the field of permanent magnet eddy current governors, can solve the problems of a large increase in the length of the extension shaft, a large axial space occupation, and a bulky mechanism, so as to improve safety and reliability. The effect of reducing the axial size and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

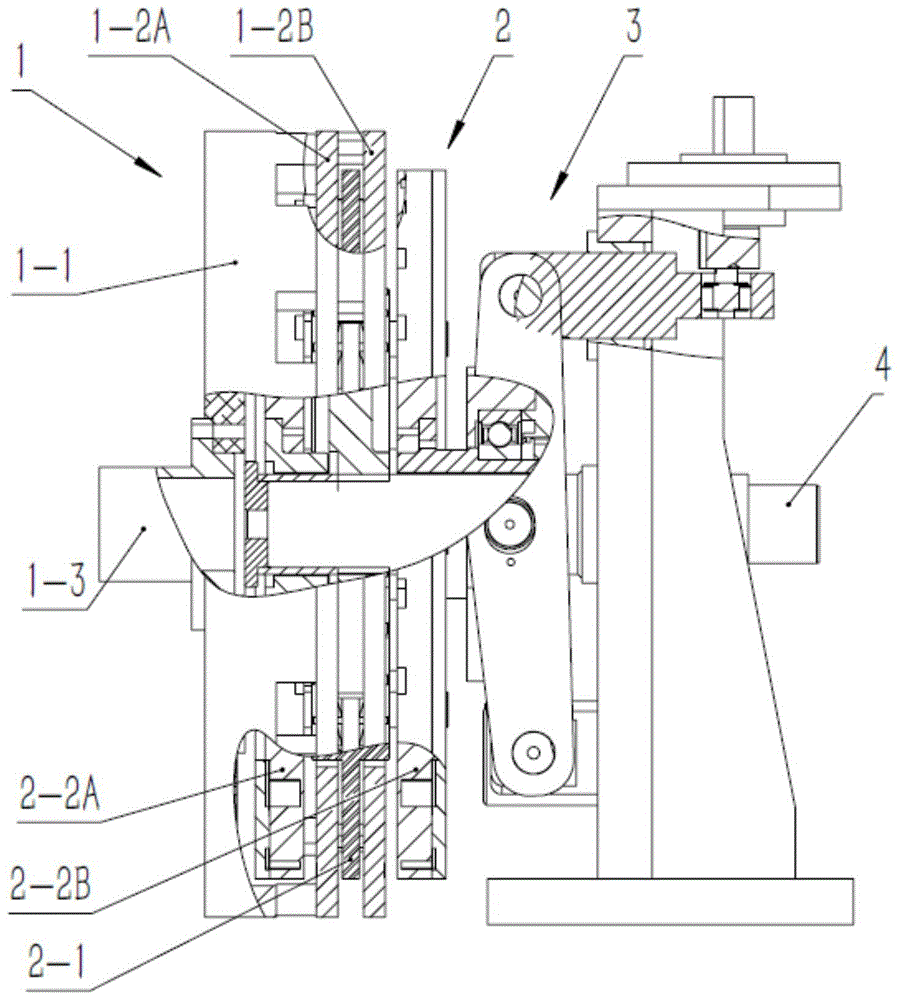

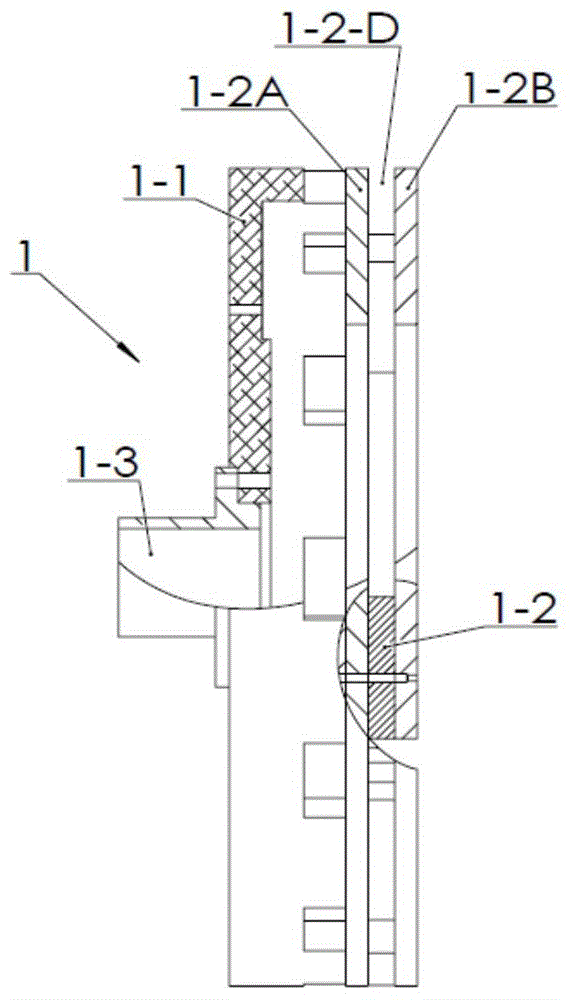

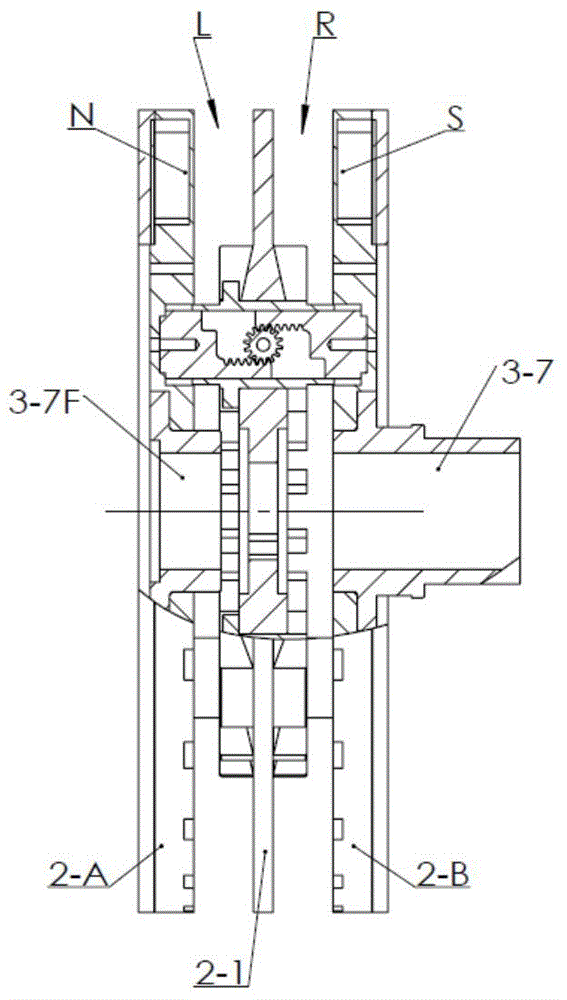

[0033] see Figures 1 to 7D As shown, a permanent magnet governor based on a conjugate-fed rotor in the present invention includes: a coaxially arranged secondary shaft (not shown) and an extended main shaft 4; the extended main shaft 4 is provided with a permanent magnet rotor 2, and the permanent The magnetic rotor 2 includes a pair of permanent magnetic disks A 2-2A and permanent magnetic disks B 2-2B arranged in parallel on the extended main shaft 4, and a conjugate feeder is arranged in parallel between the permanent magnetic disks A 2-2A and permanent magnetic disks B 2-2B. The magnetic rotor 2-1, the conjugate magnetic feed rotor 2-1 is fixedly installed on the extension main shaft 4; the permanent magnetic disk A 2-2A and the permanent magnetic disk B 2-2B are provided with permanent The magnet group; the permanent disk A 2-2A and the permanent disk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com