Three-axle power bogie based on 100% low-floor tramcar

A technology for power bogies and trams, applied in the field of steering systems, can solve problems such as weak adhesion, insufficient wheel-rail adhesion, and large axle loads, and achieve the effects of improving adhesion, climbing ability and acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

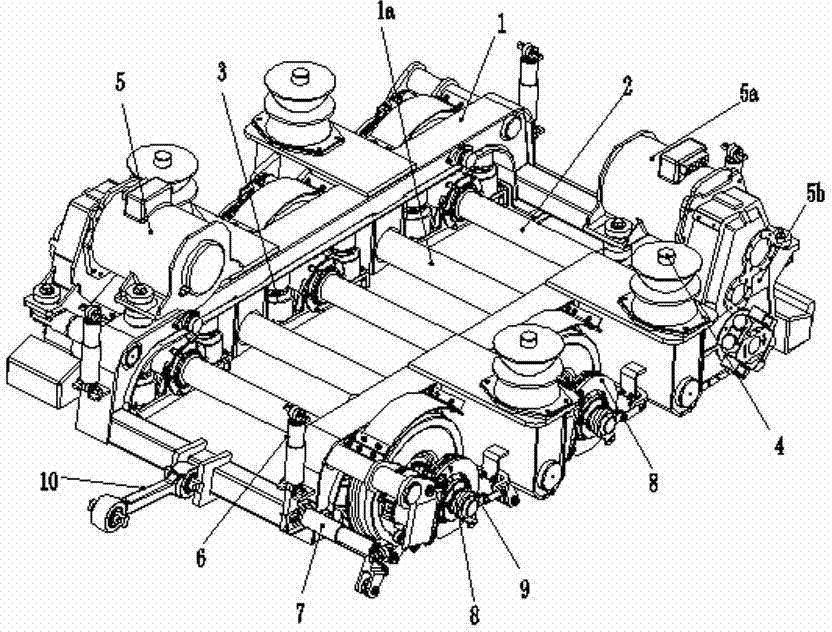

[0013] Such as figure 1 As shown, a three-axle power bogie based on a 100% low-floor tram is mainly composed of a rectangular frame 1, a wheel set device 2, a primary suspension 3, a secondary suspension 4, a power drive device 5, and a vertical damper 6. Composed of transverse damper 7, braking device 8, grounding device 9, traction rod 10, etc.

[0014] The rectangular frame 1 adopts a steel plate or casting assembly welding structure, and is a rectangular frame structure formed by welding two side beams, two cross beams and two connecting rods 1a. There are three sets of wheel set devices 2, which are arranged at intervals front and rear on the rectangular frame 1. Each set of wheel set devices 2 is mainly composed of wheel sets, axle boxes and axles, and two connecting rods 1a are arranged alternately with three axles. There are 12 primary suspensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com