Self-feeding-type permanent magnet eddy current speed regulator

A technology of eddy current and governor, which is applied in the field of mechanical transmission, can solve the problems of reduced performance, limited application range of high power, bulky and other problems, and achieve the effect of direct heat dissipation and improved power transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

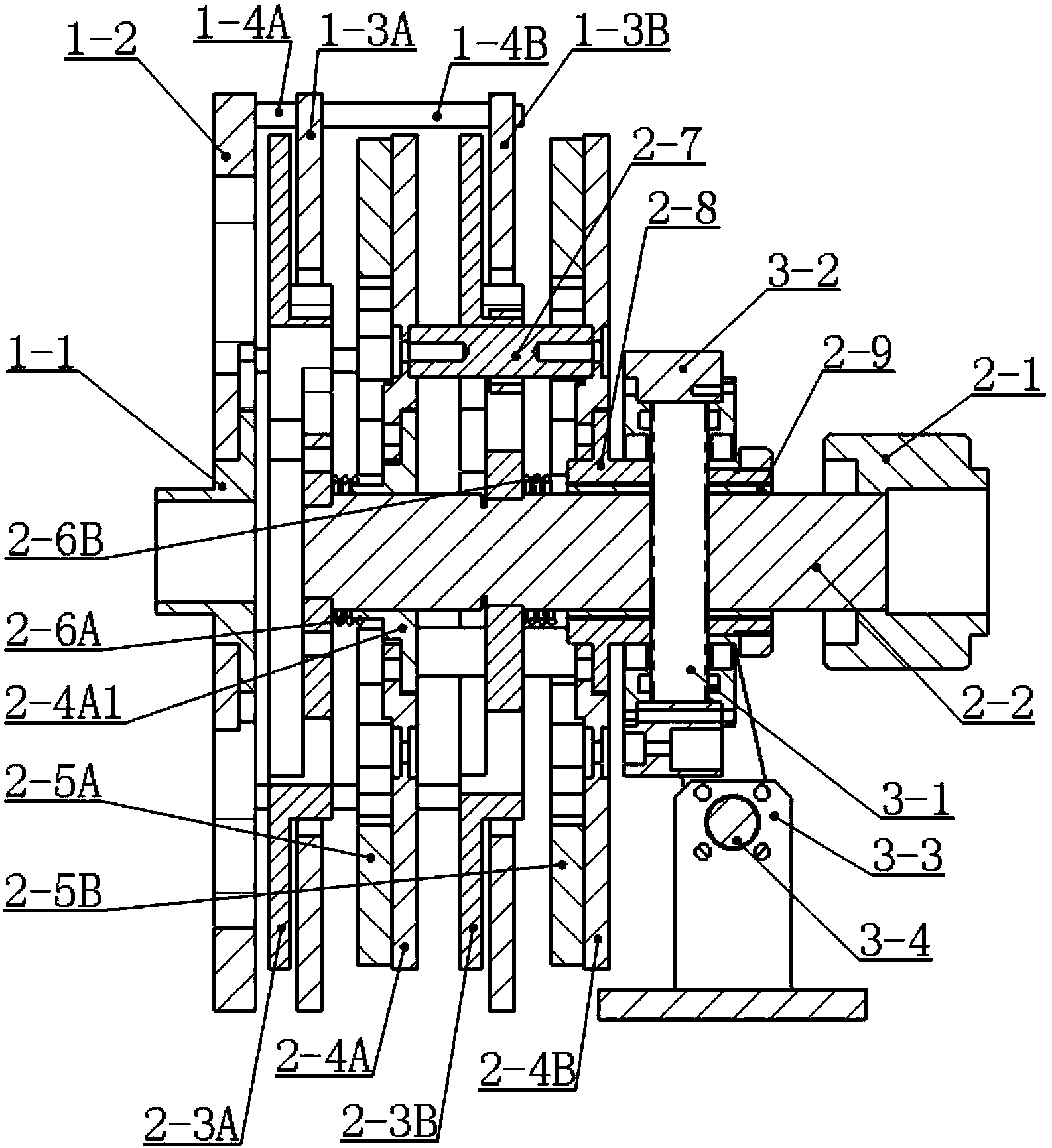

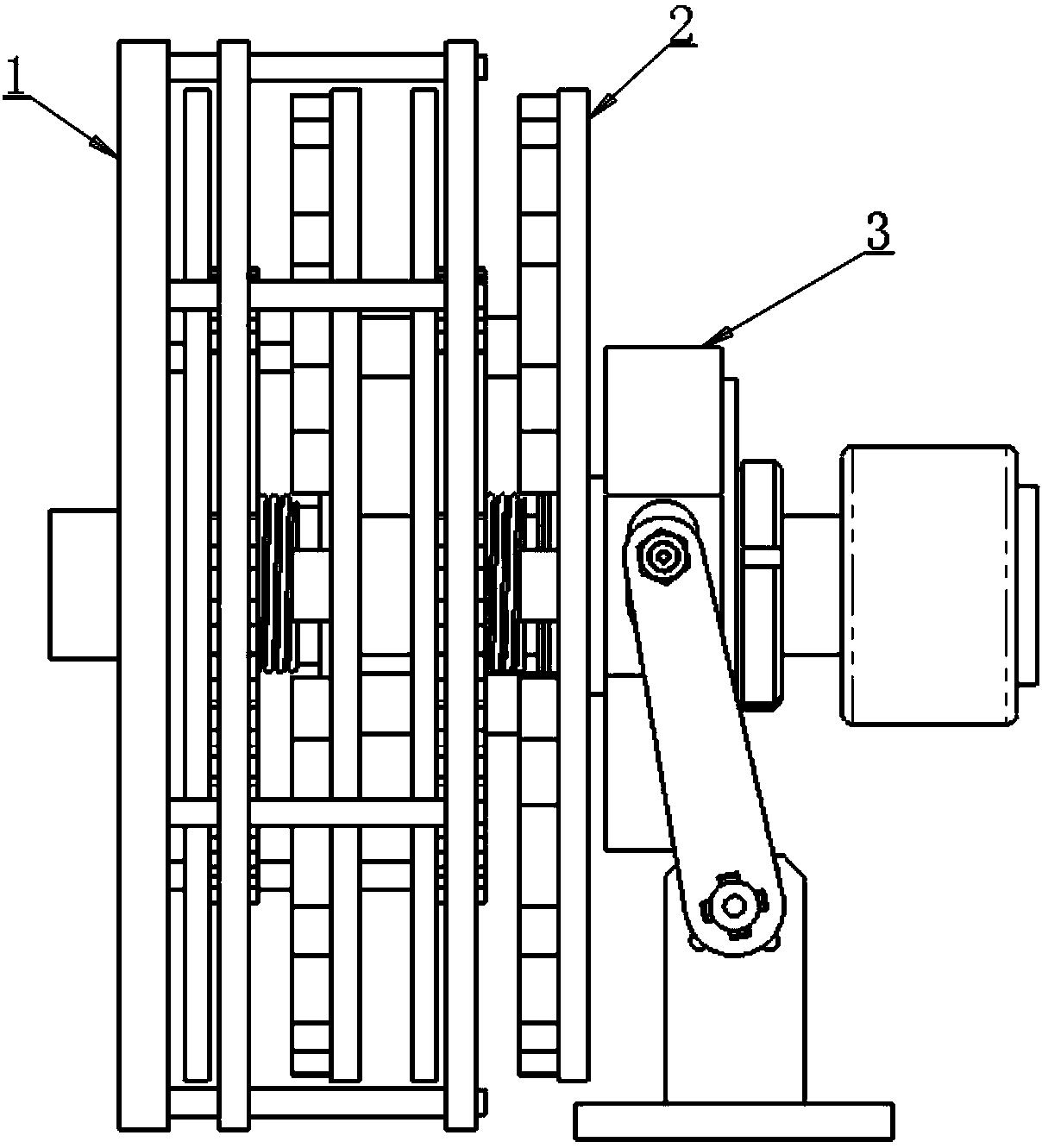

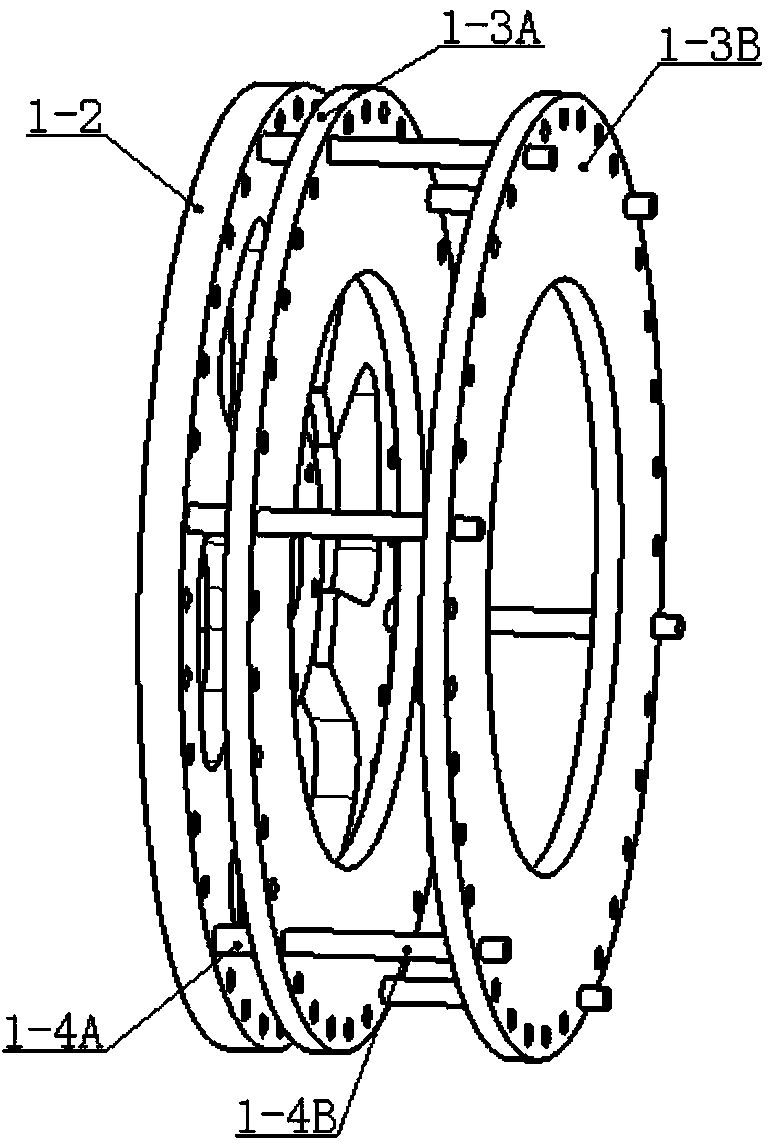

[0035] see Figure 1 to Figure 8 As shown, a self-feeding permanent magnet eddy current governor of the present invention includes a conductor rotor 1, a permanent magnet rotor 2 and a displacement adjustment mechanism 3; the conductor rotor 1 is fixed on the auxiliary shaft (not shown), and the permanent magnet rotor 2 includes an extended main shaft 2-2 arranged coaxially with the secondary shaft.

[0036] On the extension main shaft 2-2, permanent magnet rotor attached disks 2-3A and 2-3B are fixedly installed, and the permanent magnet rotor main disks 2-4A and 2-4B are sleeved on the extended main shaft 2-2; the permanent magnet rotor attached disk 2- 3A, 2-3B and permanent magnet rotor main discs 2-4A, 2-4B are arranged in parallel. The permanent magnet rotor attached disk 2-3A is provided with a central hole 2-3Z and a plurality of synchronous light r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com