LED (light-emitting diode) lamp bead

A technology of LED lamp beads and lamp beads, which is applied in lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of waste of materials, waste of electricity, temperature rise, etc., to reduce use costs, reduce production costs, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

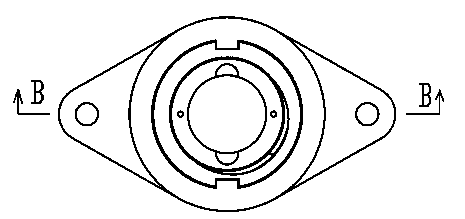

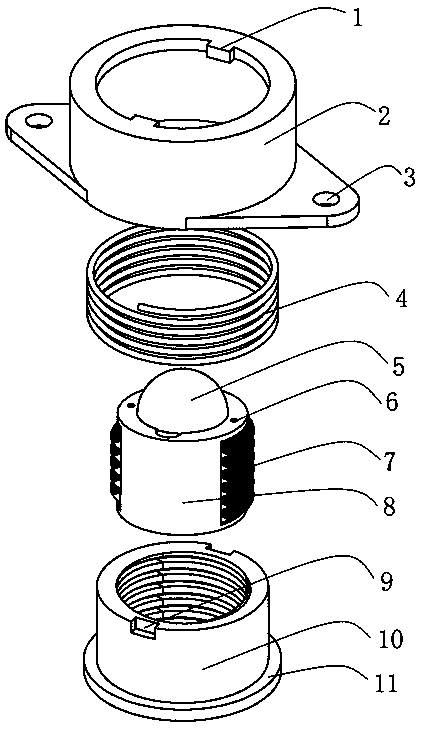

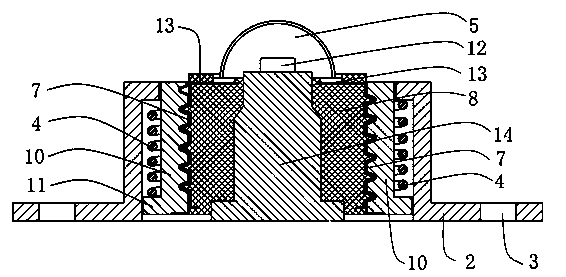

[0020] Such as Figure 1-6 As shown, the LED lamp bead of the present invention includes a lamp bead and a lamp bead holder for installing the lamp bead, wherein the lamp bead includes a light-emitting chip 12, a silica gel lens 5, a cylindrical insulating plastic 8 and positive and negative electrode welding pieces 13, and the light-emitting chip 12 is provided with a chip heat dissipation base 14, the positive and negative soldering pieces 13 are connected to the light-emitting chip 12 through conductive wires, and the outer circumference of the cylindrical insulating plastic 8 is covered with positive and negative guide plates 7 with external threads 15. The negative electrode guide plate 7 is connected with the positive and negative electrode welding pieces 13 respectively; the lamp bead holder includes the lamp bead holder inner shell 10 and the lamp bead holder outer shell 2, and the inner surface of the lamp bead holder inner shell 10 is covered with positive and negativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com