Rear axle airbag inflating and deflating system and three-axle vehicle using same

A technology of follower axle and air bag, applied in vehicle parts, elastic suspension, suspension and other directions, can solve the problems of complex lifting axle mechanism and high cost, achieve low cost, reduce axle load, and achieve simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

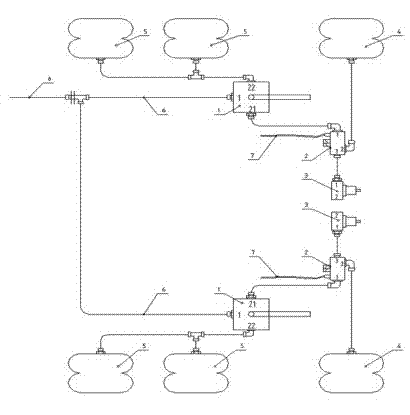

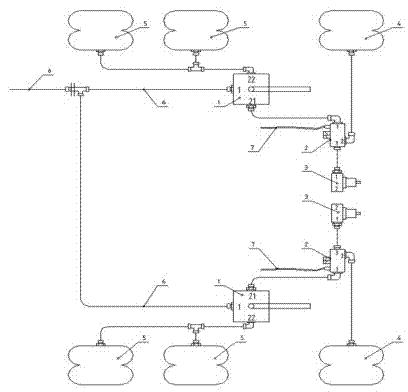

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] An embodiment of an airbag inflation and deflation system for a tag axle

[0013] like figure 1 As shown, the air bag reverse charging and discharging system of the tag axle includes two identical charging and deflation units, and each charging and deflation unit includes an air bag height control valve 1, a normally open solenoid valve 2, an overflow valve 3, a follow-up Bridge air bag 4, middle bridge air bag 5 and height control valve intake pipeline 6. The air intake line 6 of the height control valve is connected to port 1 (intake port) of the airbag height control valve 1, and port 21 (air outlet) of the air bag height control valve 1 is connected to port 1 (normal port) of the normally open solenoid valve 2 , port 22 (air outlet) of the airbag height control valve 1 is connected to the air inlet of the middle bridge airbag 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com