Exhaust gas waste heat recovery and emission reduction comprehensive application system for coal-fired boiler in thermal power plant

A technology for thermal power plants and coal-fired boilers, applied in indirect carbon dioxide emission reduction, preheating, combustion methods, etc., to achieve the effects of improving heat consumption, reducing the number of power sources, and high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

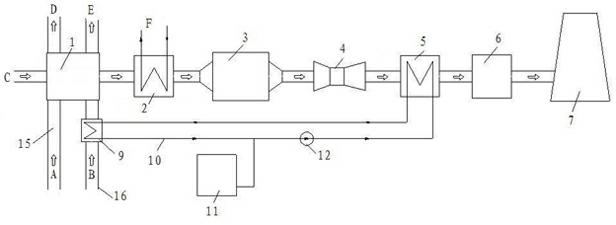

[0041] Such as figure 2 As shown, a coal-fired boiler exhaust heat recovery and emission reduction comprehensive application system in a thermal power plant, along the flow direction of the flue gas, an air preheater 1, a first Low temperature economizer 2, low and low temperature dust collector 3, induced draft fan 4, second low temperature economizer 5, desulfurization island 6, the inlet of the air preheater 1 is respectively connected with the cold primary air pipeline 15 and the cold secondary air pipeline 16 The cold secondary air pipeline 16 is provided with a secondary air heater 9, and the secondary air heater 9 communicates with the second low-temperature economizer 5 through the water medium pipeline 10, and the water medium The pipeline 10 is provided with an expansion tank 11 and a water pump 12 . There is no heating device on the cold primary air duct 15 .

[0042] The working process of this embodiment: the flue gas C comes out of the air preheater, passes th...

Embodiment 2

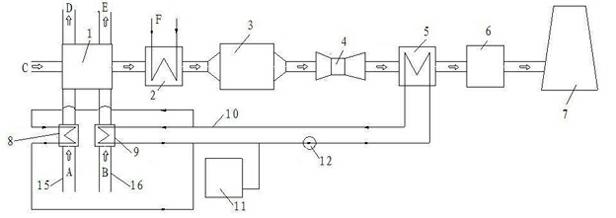

[0044] Such as image 3 As shown, a coal-fired boiler exhaust heat recovery and emission reduction comprehensive application system in a thermal power plant, along the flow direction of the flue gas, an air preheater 1, a first Low temperature economizer 2, low and low temperature dust collector 3, induced draft fan 4, second low temperature economizer 5, desulfurization island 6, the inlet of the air preheater 1 is respectively connected with the cold primary air pipeline 15 and the cold secondary air pipeline 16 The cold secondary air pipeline 16 is provided with a secondary air heater 9, and the secondary air heater 9 communicates with the second low-temperature economizer 5 through the water medium pipeline 10, and the water medium The pipeline 10 is provided with an expansion tank 11 and a water pump 12 . The cold primary air pipeline 15 is provided with a primary air heater 8 , and the primary air heater 8 and the secondary air heater 9 share the same water medium pipel...

Embodiment 3

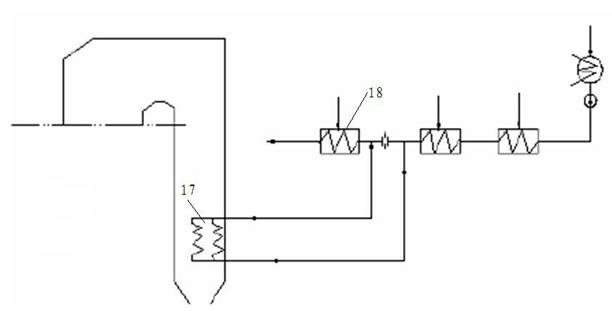

[0048] Such as Figure 4 As shown, a coal-fired boiler exhaust heat recovery and emission reduction comprehensive application system in a thermal power plant, along the flow direction of the flue gas, an air preheater 1, a first Low temperature economizer 2, low and low temperature dust collector 3, induced draft fan 4, second low temperature economizer 5, desulfurization island 6, the inlet of the air preheater 1 is respectively connected with the cold primary air pipeline 15 and the cold secondary air pipeline 16 The cold secondary air pipeline 16 is provided with a secondary air heater 9, and the secondary air heater 9 communicates with the second low-temperature economizer 5 through the water medium pipeline 10, and the water medium The pipeline 10 is provided with an expansion tank 11 and a water pump 12 .

[0049] The primary air heater 8 is arranged on the cold primary air pipeline 15, and the primary air heater 8 is connected with the low-pressure heater from the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com