Integrated thermal management system for electric vehicles

A thermal management system and management system technology are applied in the field of integrated thermal management systems for electric vehicles, which can solve the problems of reducing battery power density and energy density, increasing vehicle energy consumption and cost, and consuming battery energy, and reducing energy consumption. The effect of consumption, reasonable structure design and reasonable structure layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

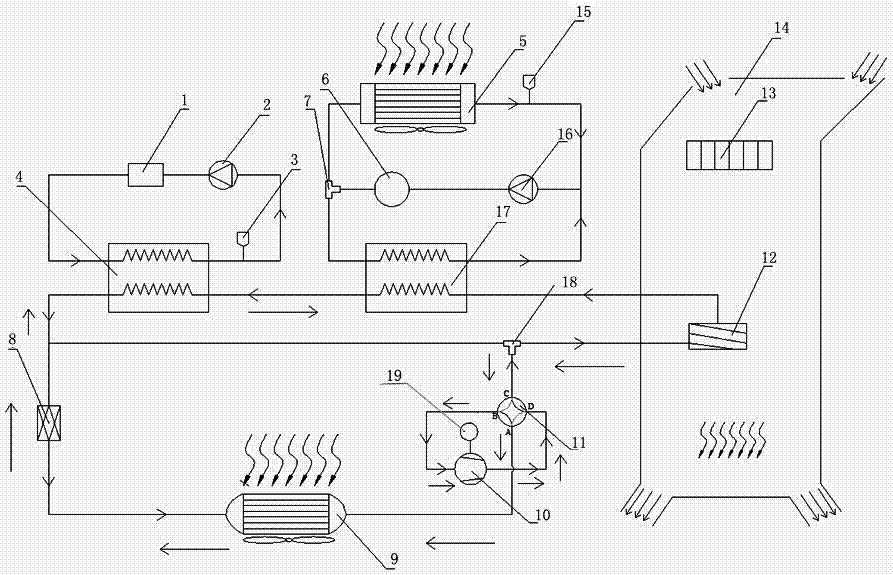

[0025] see figure 1 An electric vehicle integrated thermal management system includes a battery integrated thermal management system, a motor integrated thermal management system, and a cooling and heating cycle system of a heat pump air conditioner.

[0026] The battery integrated thermal management system includes the first water pump 2, the first phase-change heat exchanger 4, the first expansion kettle 3 and the battery water-cooling coil 1, the battery water-cooling coil 1, the first water pump 2, and the first phase-change heat exchanger The first phase change branch of 4 and the first expansion kettle 3 are connected in series in sequence; the working fluid of the battery integrated thermal management system is water; the battery water cooling coil 1 is in contact with the car battery.

[0027] The motor integrated thermal management system includes a second water pump 16, a second phase-change heat exchanger 17, a second expansion kettle 15, a radiator 5 and a first mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com