Cooling fluid temperature control system for testing engine performance

A technology of temperature control system and coolant, which is applied in the direction of engine testing, machine/structural component testing, measuring devices, etc. It can solve the problems of large engine gap, ineffective exhaust, and inability to truly reflect the engine testing requirements, etc. To achieve the effect of increasing the water flow in and out and reducing the pressure difference between the water in and out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

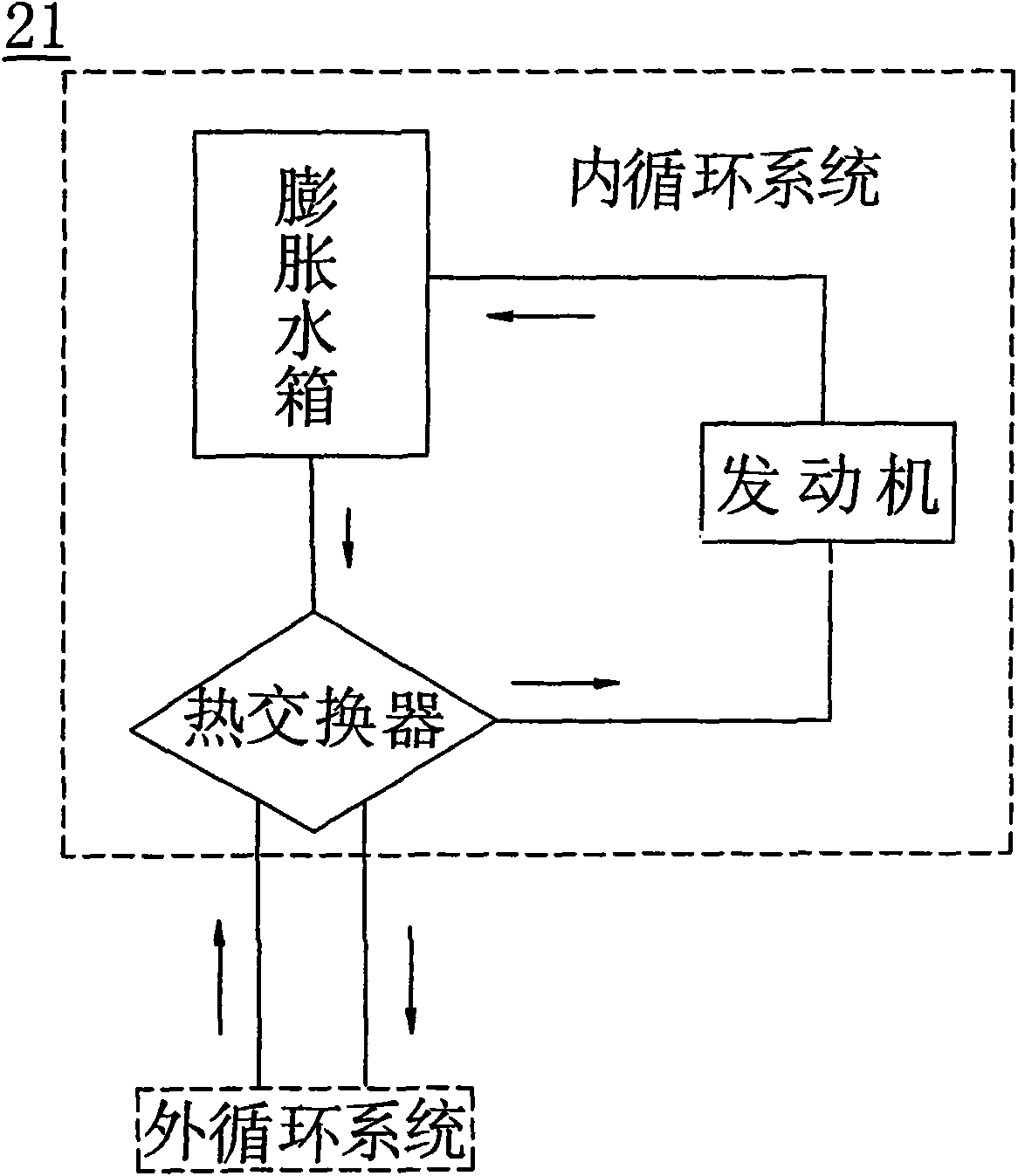

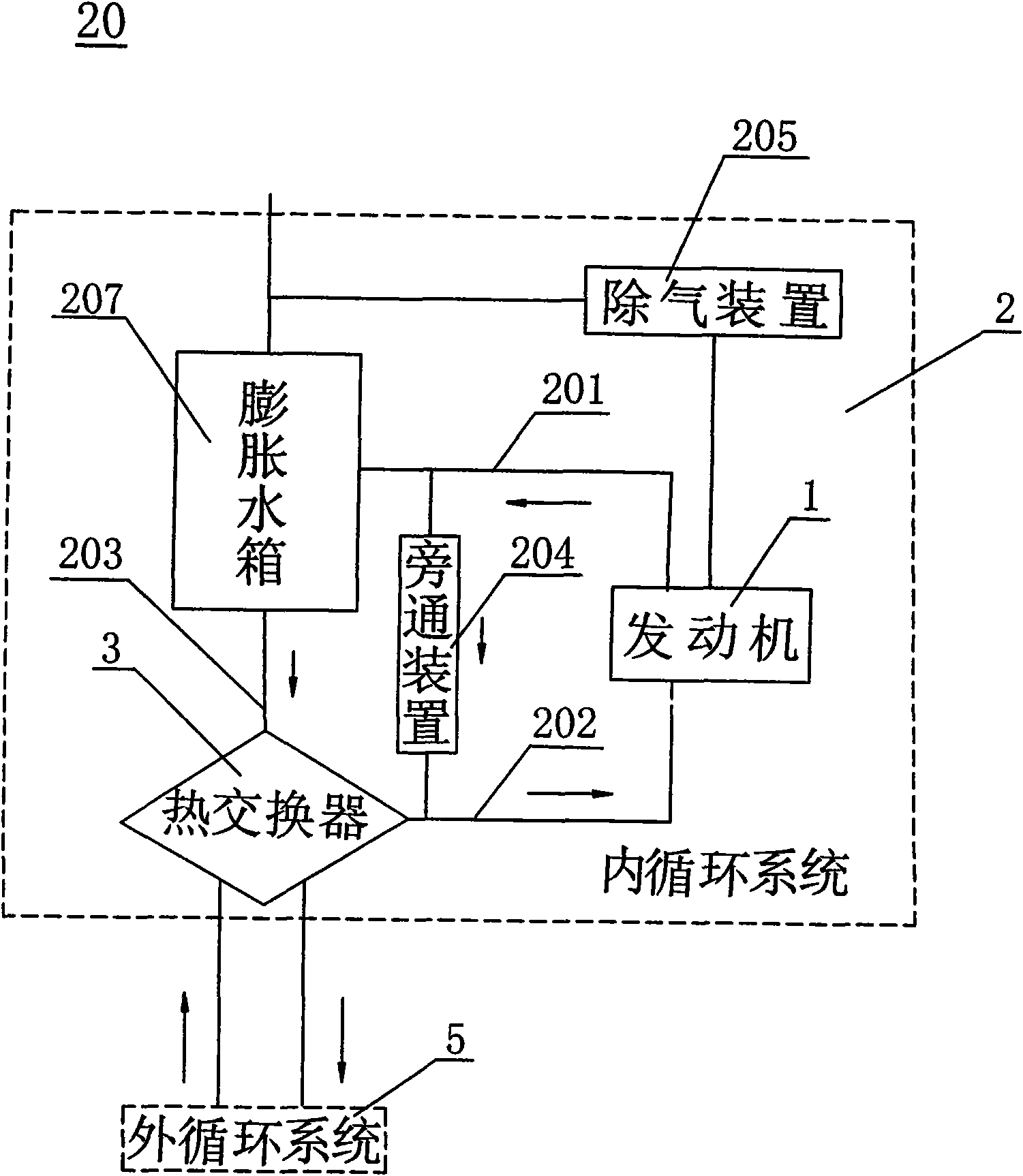

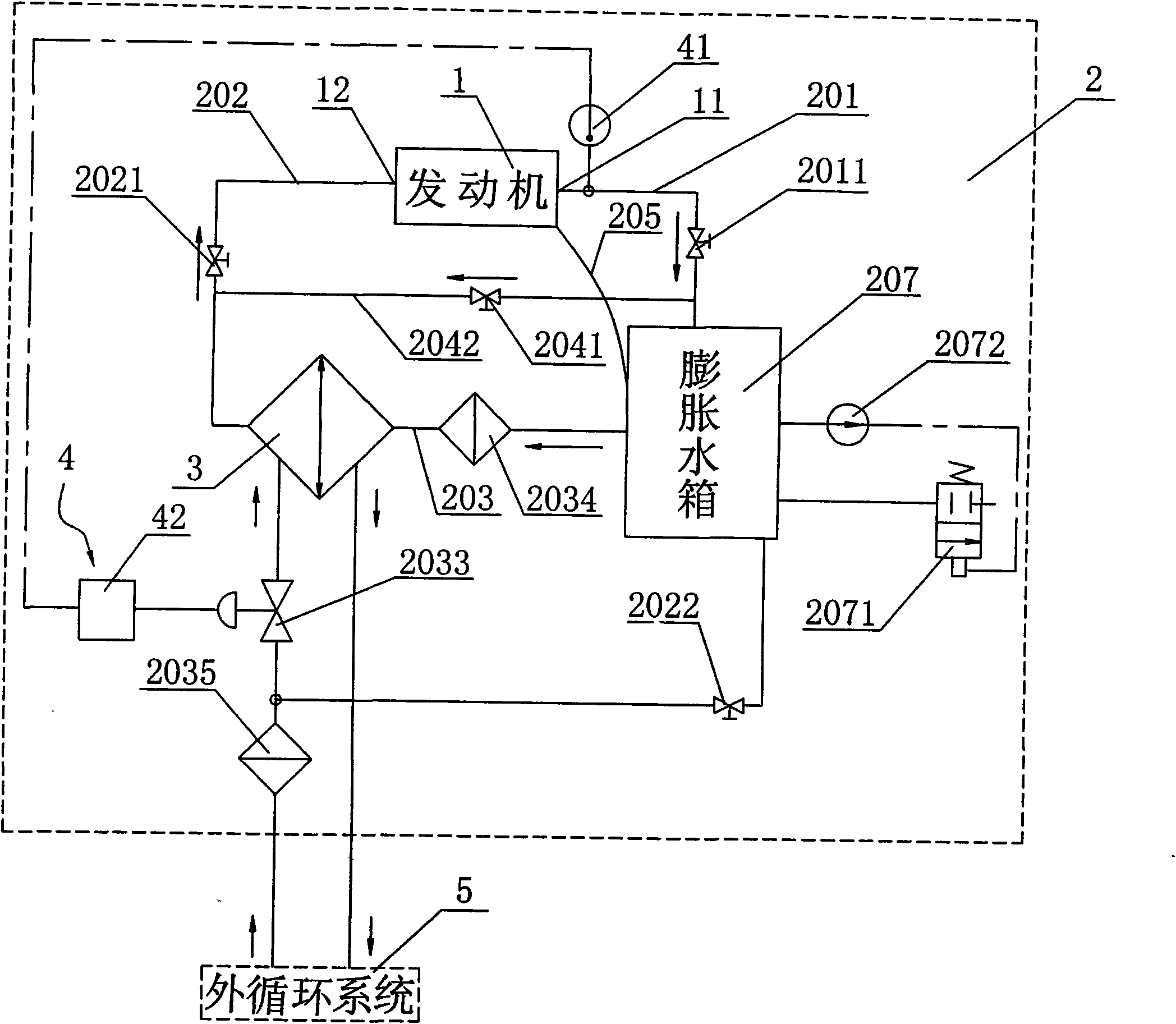

[0054] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0055] The cooling liquid described in the present invention may be water or other cooling liquids. In this embodiment, water or cooling liquid circulates in the internal circulation system, and water circulates in the external circulation system, but this is not limited thereto. The external circulation system of the present invention is a prior art, and will not be described in detail here. The internal circulation system of the present invention will be described in detail below.

[0056] During the engine test process, it is often necessary to simulate the vehicle condition and various complex test conditions for test control. Engine circulating water control is of great significance in engine testing, which directly ensures whether the engine can be tested and operated normally. The conventional circulating water temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com