Three-pack power battery cooling and heating system of new energy automobile

A new energy vehicle and power battery technology, applied in electric vehicles, secondary batteries, battery pack components, etc., can solve the problems of inconsistent coolant flow, non-compliance with the cooling system, difficult flow distribution, etc., to ensure safety and reliability. Service life and the effect of ensuring temperature consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

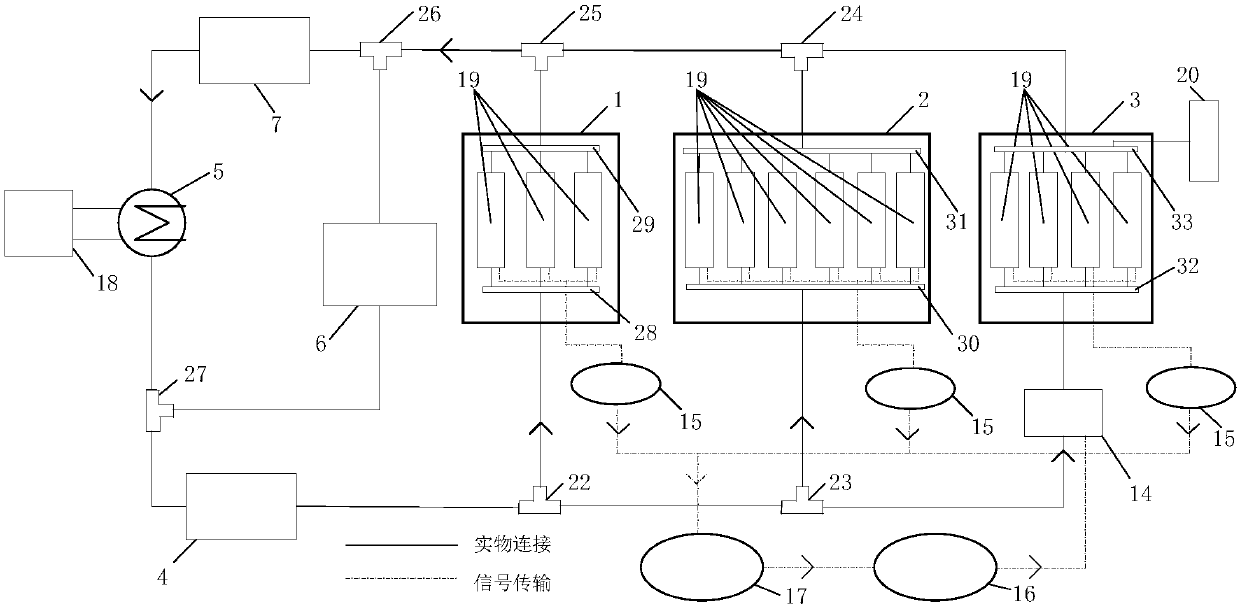

[0041] The present invention is described in detail below in conjunction with accompanying drawing:

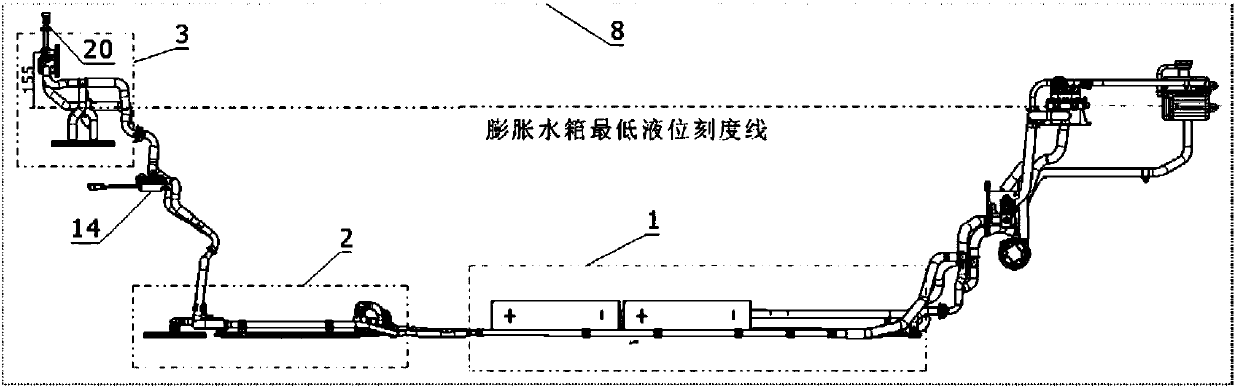

[0042] A three-pack power battery cooling and heating system for a new energy vehicle, including three power battery packs, a high-pressure water heating heater 4, a plate heat exchanger 5, an expansion tank 6, and an electronic water pump 7, the three power battery packs and the circuit of the whole vehicle System connection, the first battery pack 1 and the second battery pack 2 are arranged at the lower part of the chassis of the vehicle body, and the third battery pack 3 is arranged inside the trunk of the vehicle.

[0043] The first battery pack 1 includes three battery modules 19 , the second battery pack 2 includes six battery modules 19 , and the third battery pack 19 includes four battery modules 19 . The first battery pack 1 has the internal water cooling structure of the first battery pack, the second battery pack 2 has the internal water cooling structure of the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com