Three-dimensional heat-pipe heat exchanger and production method thereof

A heat exchanger and three-dimensional heat pipe technology, applied in the field of heat transfer, can solve the problems of fixed structure, difficult heat pipe manufacturing, impractical application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings.

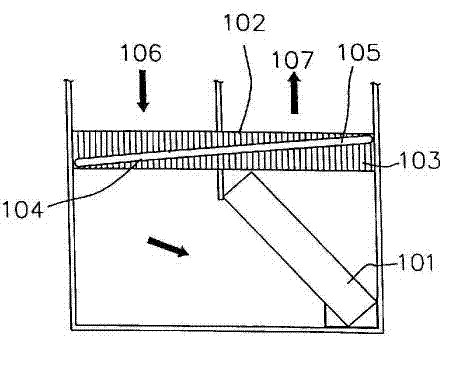

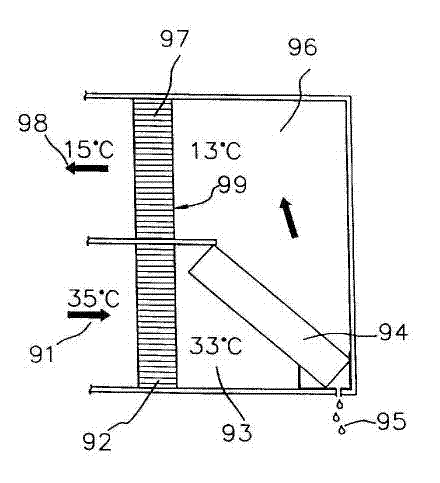

[0054] According to the present invention, the heat pipe heat exchanger is in the form of serpentine heat pipes, and through the connection of U-shaped pipes, the heat pipes can form a fully continuous coil.

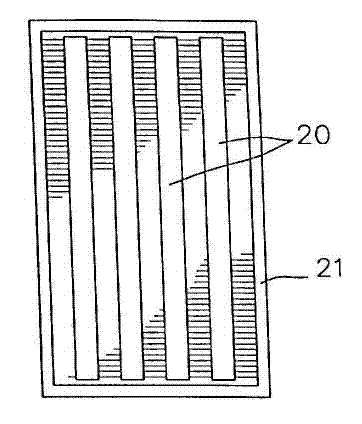

[0055] Such as Figure 3B As shown, in the heat pipe heat exchanger 38 manufactured according to the present invention, the open ends of adjacent U-shaped pipes 30 are connected to each other through a U-shaped elbow 31 , thereby forming a serpentine heat pipe 36 . Heat conduction fins 32 , preferably aluminum fins, are sheathed on the outside of the heat pipe to form a serpentine heat pipe heat exchanger 38 . Each U-shaped pipe 30 does not use a liquid-absorbing core, but makes micro-grooves 33 on the inner wall of the pipe, so that more heat can be transmitted.

[0056] Figure 3B Before using the heat pipe heat exchanger 38 shown in , a predetermined amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com