Integral heat pipe heat exchanger

A heat exchanger, heat pipe heat exchanger technology, applied in the direction of heat exchange equipment, heat exchanger type, heat exchanger shell, etc., can solve the problems of temperature gradient loss, many consumables, limited heat exchange efficiency, etc. The effect of large ratio, high heat transfer efficiency, and small fluid resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

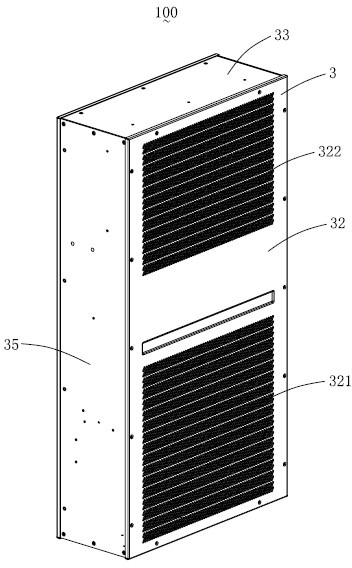

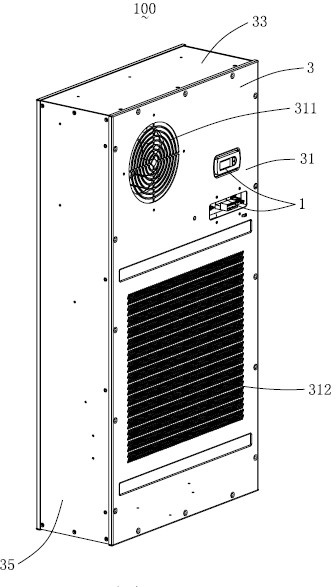

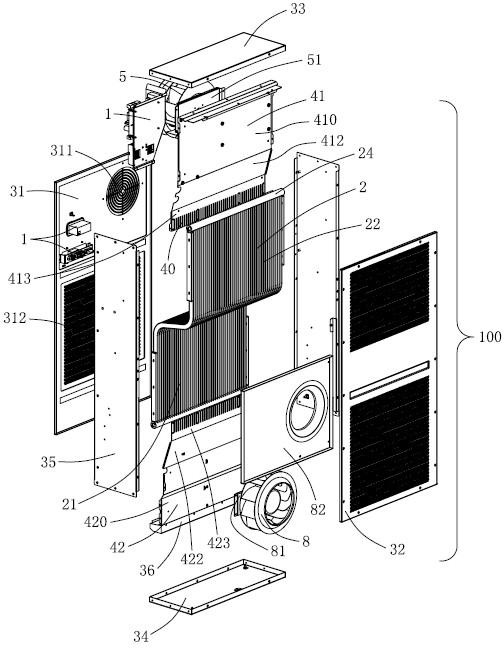

[0024] The present invention provides an integral heat pipe heat exchanger 100 using a heat pipe as a heat exchange device. The heat pipe is a heat transfer element with high thermal conductivity. It transfers heat through the evaporation and condensation of the working fluid in the fully enclosed vacuum tube shell. It has extremely high thermal conductivity, good isothermal performance, and heat transfer on both sides of the cold and hot It has a series of advantages such as the area can be changed arbitrarily, long-distance heat transfer, and temperature control. The heat pipe heat exchanger composed of heat pipes has the advantages of high heat transfer efficiency, small fluid resistance loss, and large work-to-heat ratio. Moreover, the heat pipe heat exchanger does not need a compressor, does not need Freon working fluid, and has a compact structure and a small mass and shape.

[0025] The working principle of the heat pipe is to use the evaporation and condensation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com