Two-stage precooling dehumidification device and method

A pre-cooling and evaporative technology, applied in the field of air-conditioning equipment, can solve the problems of insignificant energy saving effect, large energy consumption, and small air volume, and achieve the effect of increasing the dehumidification per unit input power, reducing redundant devices, and improving the energy efficiency of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

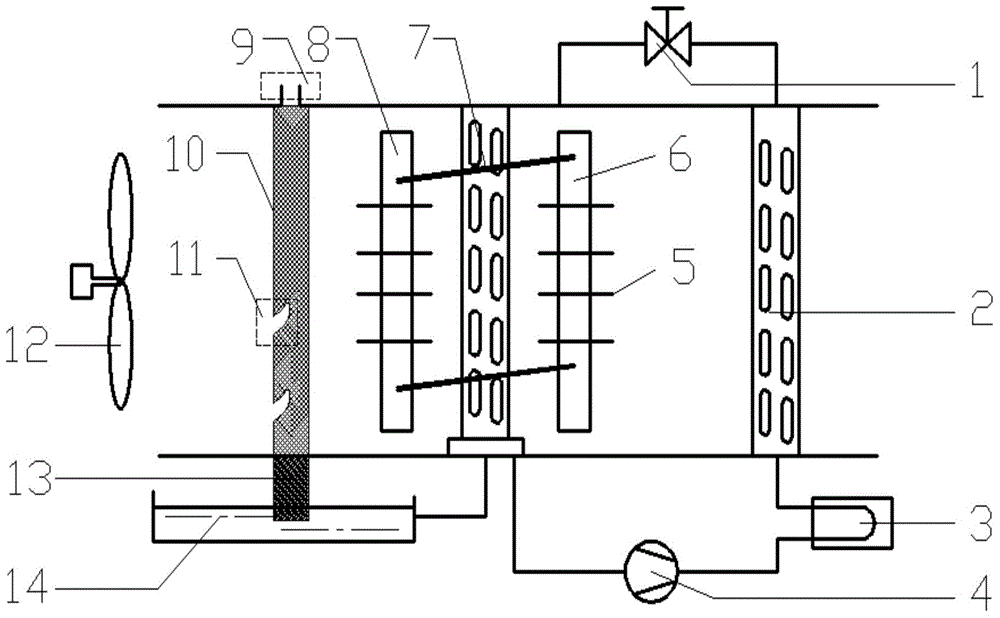

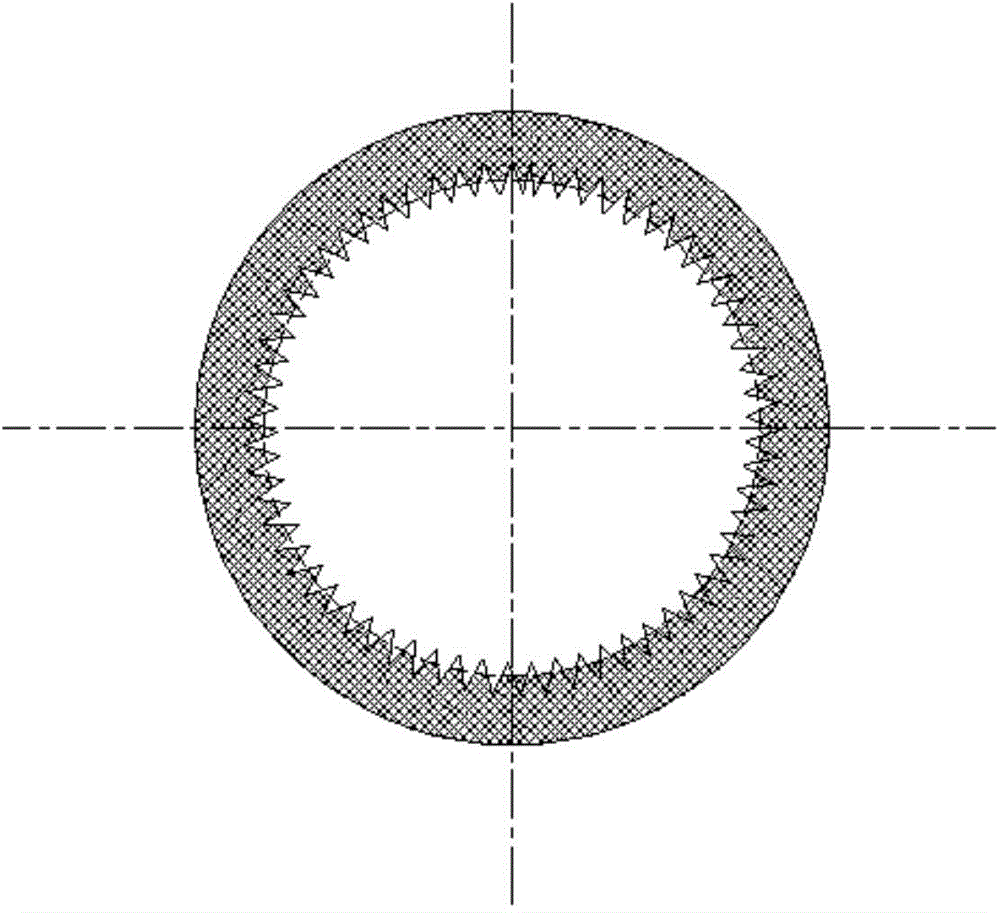

[0018] As shown in the figure, 1 is the throttling device of the refrigeration system, 2 is the air-cooled condenser of the refrigeration system, 3 is the water-cooled condenser, 4 is the compressor, 5 is the fin, 6 is the two-phase closed thermosiphon condensing section, 7 evaporator (surface cooler) of the refrigeration system, 8 two-phase closed thermosiphon evaporating section, 9 is the air outlet, 10 is the indirect evaporative circular tube surface heat exchanger, 11 is the variable-section nozzle, 12 is the induced draft fan, 13 is the near-ground end of the round pipe (filled with porous material), and 14 is the condensation water tank. The heat pipe device adopts a two-phase closed thermosiphon, which includes a heat pipe evaporation section, a condensation section and two working fluid circulation channels. The evaporation and condensation of the working fluid are used to transfer heat, and the working fluid circulates automatically without external power.

[0019] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com