Method and device for heat supply of rotary hearth furnace

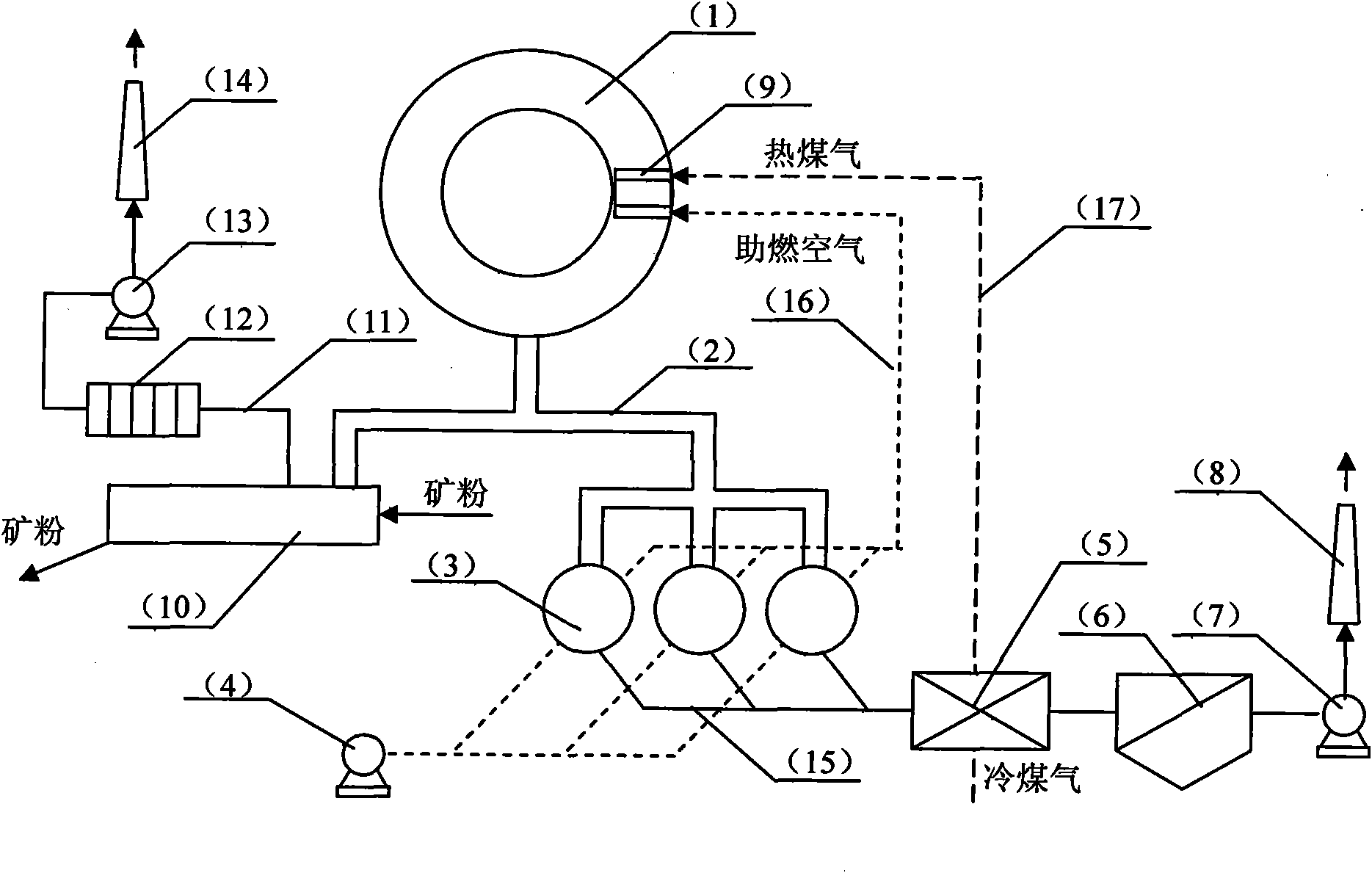

A technology of rotary hearth furnace and hot blast stove, which is applied in the direction of furnace, waste heat treatment, furnace components, etc. It can solve the problems of high energy consumption, excessive power consumption, and inability to operate, and achieve good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

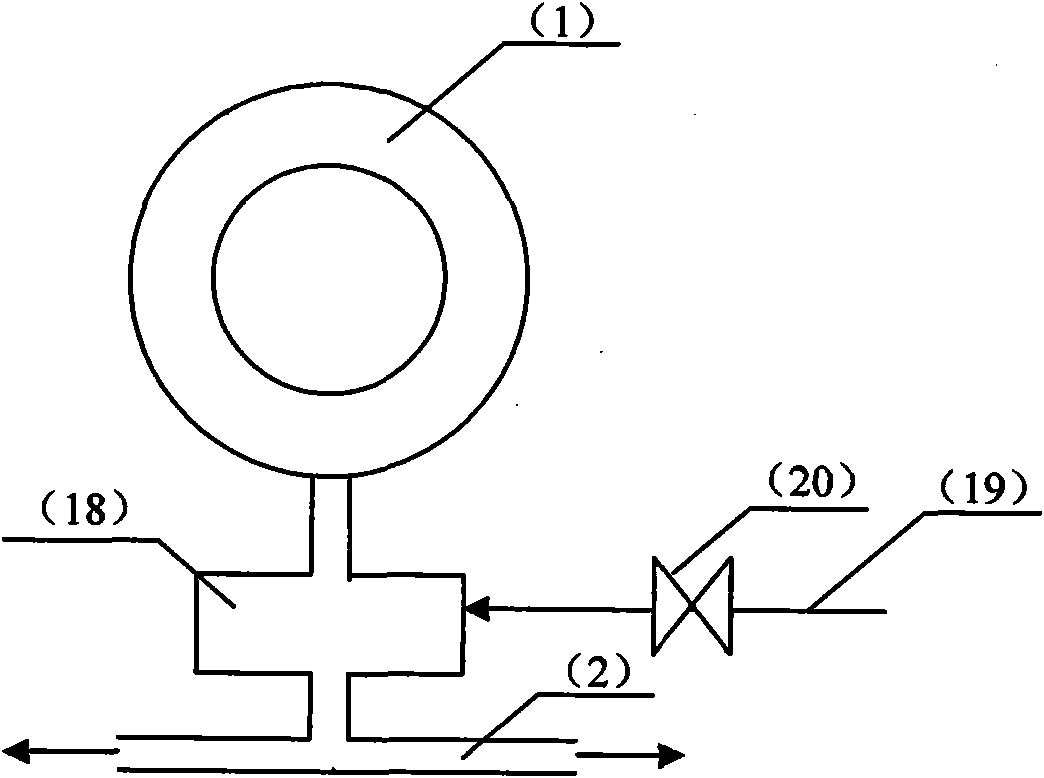

Method used

Image

Examples

Embodiment 1

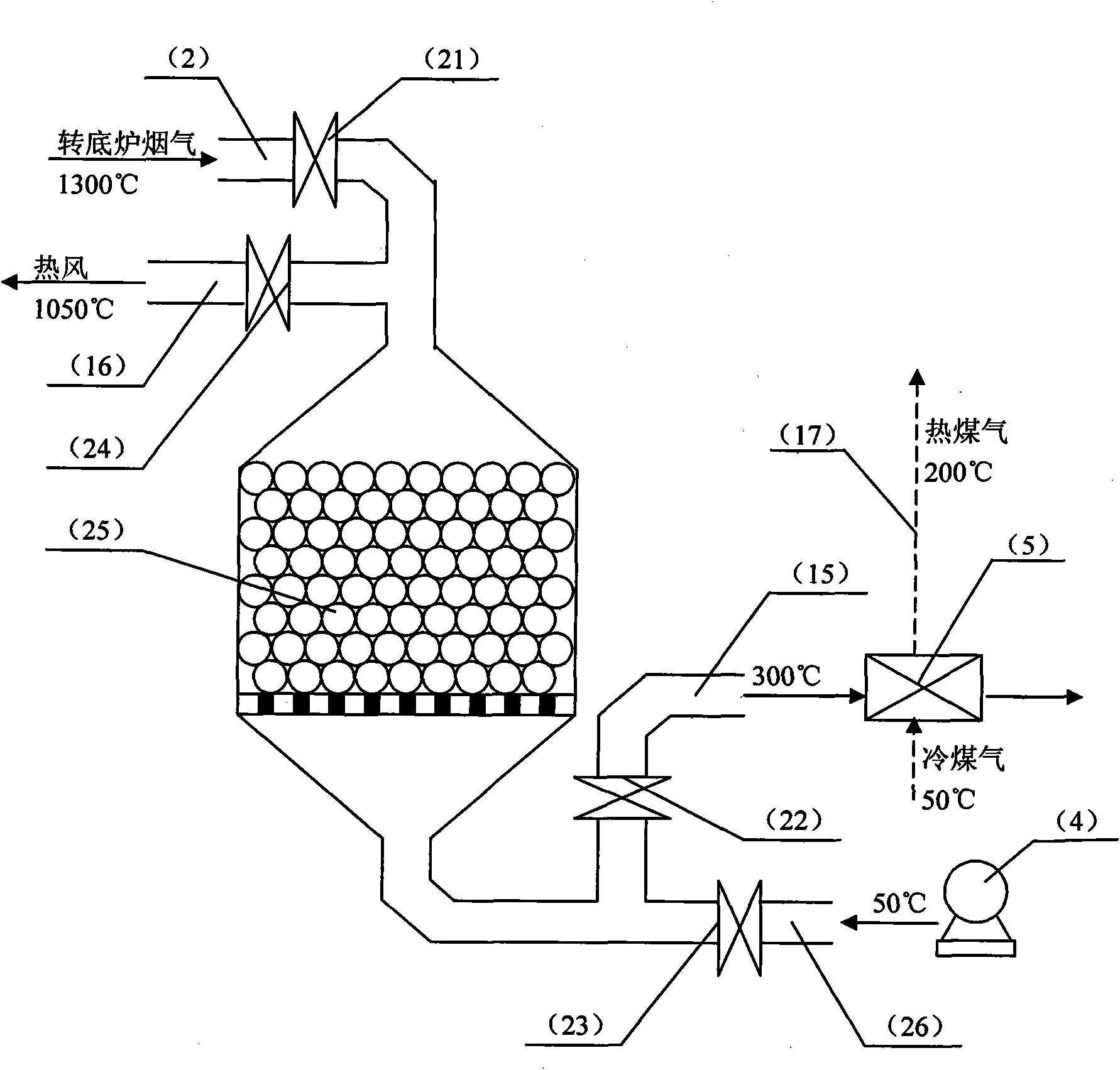

[0055] Rotary hearth furnace 1 input briquette quantity is 8t / h, gas quantity (50℃) is 3200m 3 / h, combustion air volume (50 ℃) 6500m 3 / h, the corresponding flue gas volume is 54113.8m 3 / h, the flue gas temperature is 1300°C, the preheated combustion-supporting air temperature reaches 1035°C, the water content of the mineral powder is reduced from 11% to 0.725% after the mineral powder is dried, and the hot blast stove 3 furnace replacement cycle is 25min.

Embodiment 2

[0057] Rotary hearth furnace 1 input briquette quantity is 5t / h, gas quantity (50℃) 2000m 3 / h, combustion air volume (50 ℃) 4062.5m 3 / h, the corresponding flue gas volume is 33821.17m 3 / h, the flue gas temperature is 1300°C, the preheated combustion-supporting air temperature reaches 1025°C, the water content of the mineral powder is reduced from 10% to 0.93% after the mineral powder is dried, and the hot blast stove 3 furnace replacement cycle is 34min.

Embodiment 3

[0059] Rotary hearth furnace 1 input briquette quantity is 11.5t / h, gas quantity (50℃) 4000m 3 / h, combustion air volume (50 ℃) 9343.75m 3 / h, the corresponding flue gas volume is 77788.69m 3 / h The flue gas temperature is 1300°C, the temperature of the preheated combustion air reaches 1052°C, the water content of the mineral powder is reduced from 12% to 0.528% after the mineral powder is dried, and the hot blast stove 3 replacement cycle is 17min.

[0060] The present invention adopts double preheating and graded heat exchange technology of fuel and combustion-supporting air, adopts a waste heat utilization device combined with a spherical hot blast furnace, a fire tube rotary dryer, and a heat pipe heat exchanger, and introduces a part of the 1300°C high-temperature flue gas into the converter. Bottom furnace combustion-supporting air heat exchange system, preheats the combustion-supporting cold air to 1000℃~1050℃, preheats the gas to 200℃, and the burner 9 used uses 200℃ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com