Comprehensive energy-saving device for recovery of waste heat of ultrasonic dish-washing machine

A technology of waste heat recovery and energy-saving device, which is applied to household cleaning devices, tableware washing machines/washing machines, tableware washing machines/rinsing machine parts, etc. Recovery method, high temperature of hot water for washing, high moisture content of hot air, etc., to achieve the effects of high system water utilization efficiency, small water flow resistance, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

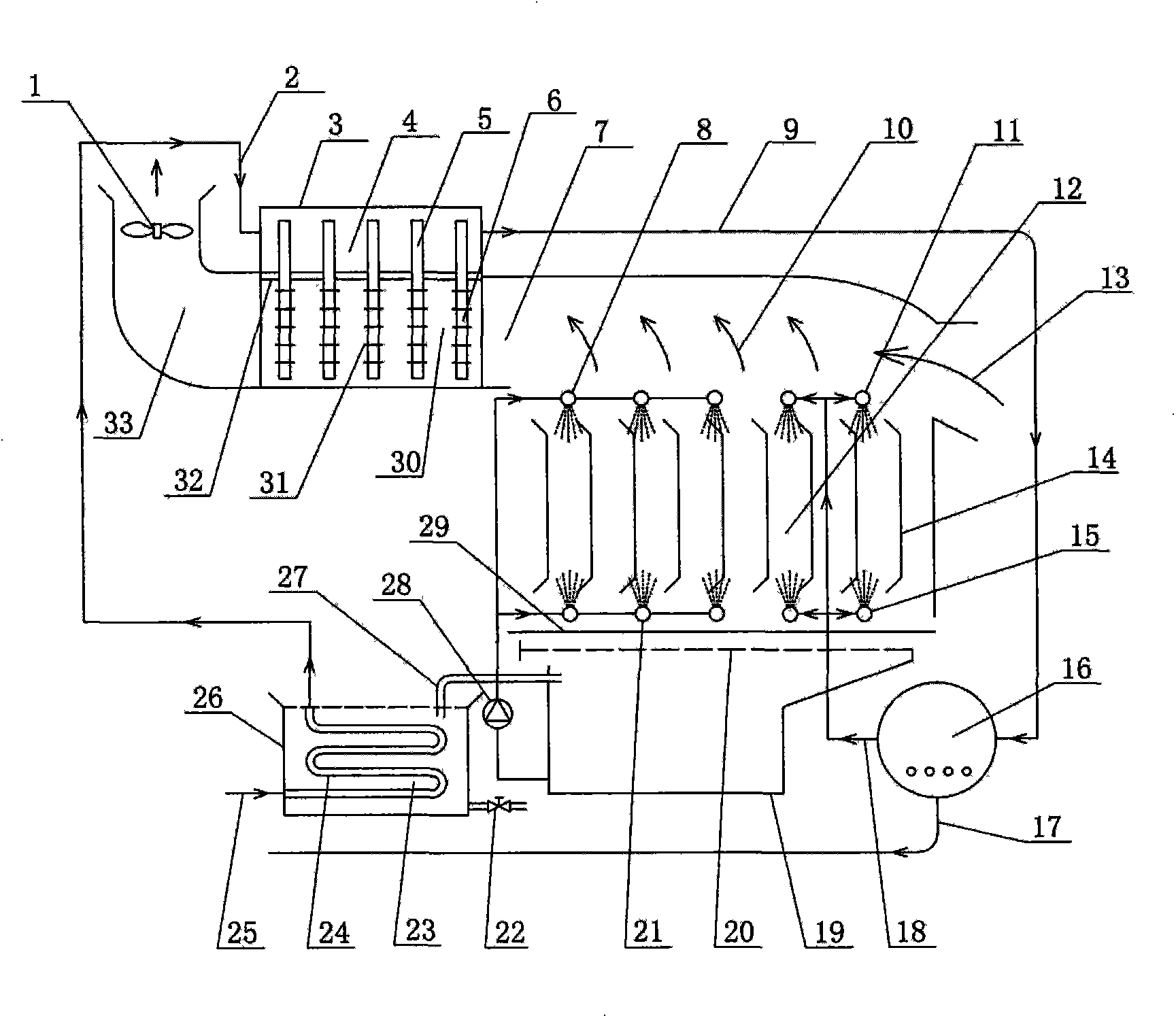

[0017] As shown in the drawings, the waste heat recovery device for an ultrasonic dishwasher according to the embodiment of the present invention includes an ultrasonic washing section (not shown), a rinsing and cleaning section 12, and a drying and disinfection section (not shown). The heat pipe heat exchanger is located on the upper left side of the washing and cleaning section, close to the air outlet; the heat pipe heat exchanger is divided into the air side of the heat exchanger and the water side of the heat exchanger under the separation of the partition plate 32; the lower part is the heat exchanger The gas side 30, the upper part is the water side 4 of the heat exchanger, and the length of the heat pipe on the gas side of the heat exchanger is about 1.8 to 2.2 times the length of the heat pipe on the water side of the heat exchanger. There are heat pipe fins 31 outside the heat pipe on the gas side of the heat exchanger, which are used to expand the heat exchange area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com