Combined opening and closing type circulating heat pump drying system

A heat pump drying, open and closed technology, applied in the direction of fluid circulation arrangement, drying gas arrangement, drying, etc., can solve the problems of low temperature in the drying room, unresolved, heat can not be discharged, etc., to achieve small temperature fluctuations and dehumidification effects. Good, solve the effect of incomplete defrosting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

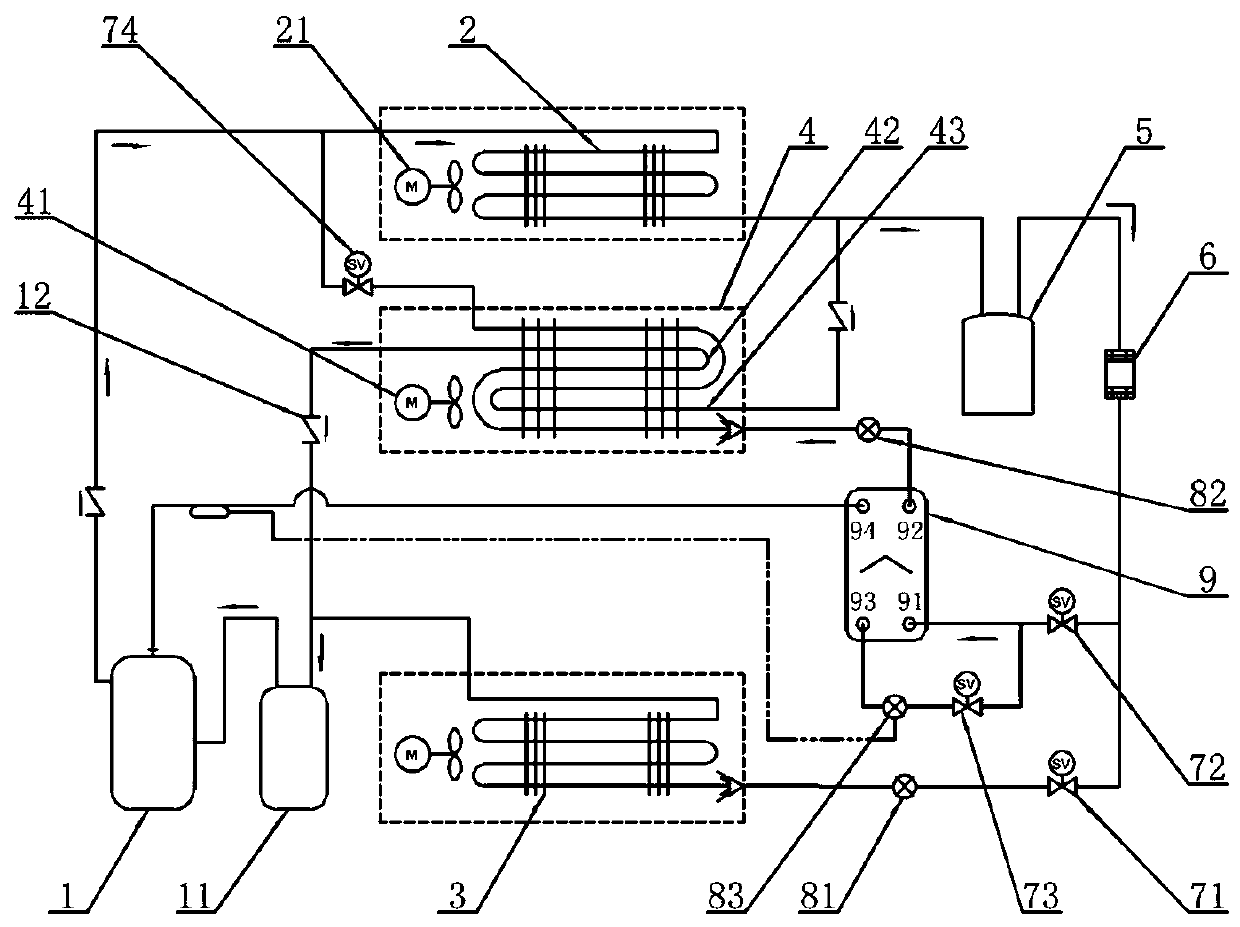

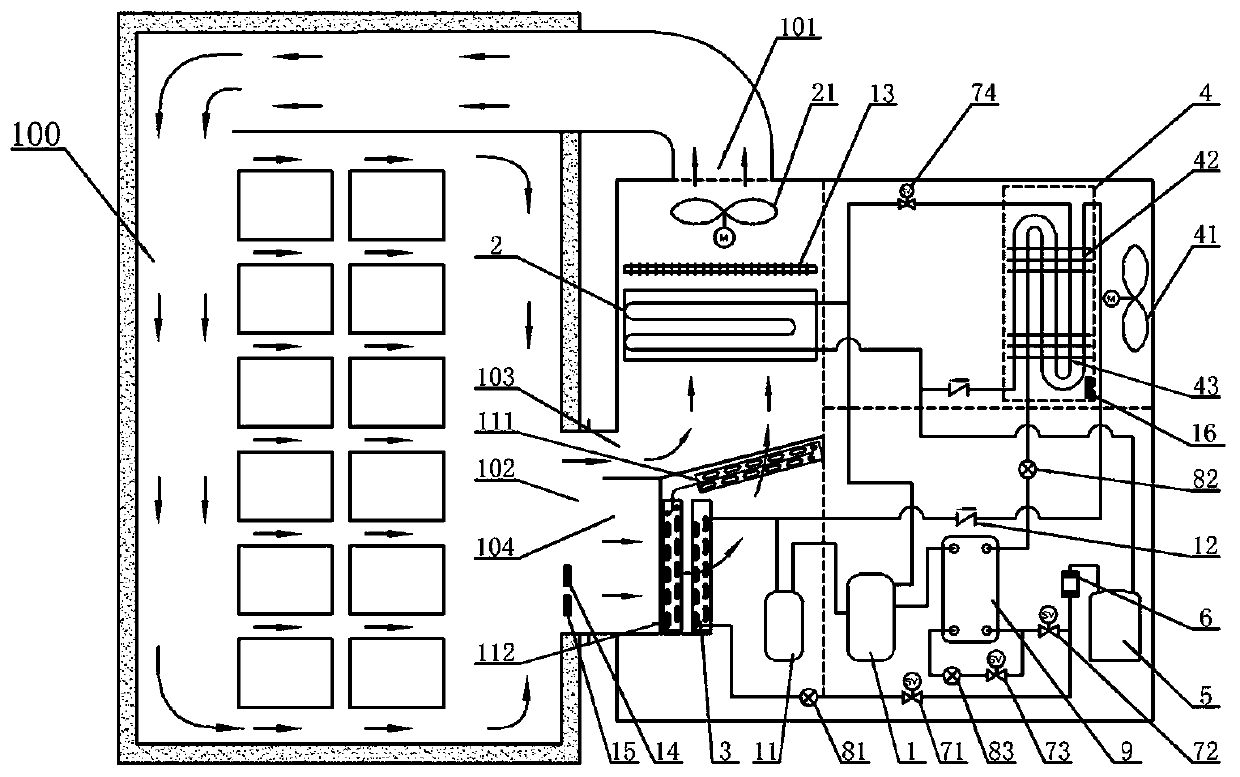

[0034] Embodiment 1: as figure 1 , 2 As shown, a composite open-close cycle heat pump drying system includes a drying room 100, a heat pump drying subsystem, a drying air circulation subsystem and a control subsystem.

[0035]The heat pump drying subsystem includes compressor 1, main condenser 2, indoor evaporator 3, outdoor heat exchanger 4, liquid receiver 5, dry filter 6, gas-liquid separator 11 and economizer 9; the outdoor heat exchanger 4 includes an outdoor fan 41, an outdoor evaporator 42 and an outdoor condenser 43; the exhaust port of the compressor 1 communicates with the inlet of the main condenser 2 and the inlet of the outdoor condenser 43 respectively, and the outlet of the main condenser 2 and the outdoor condensing The outlet of the device 43 is respectively connected with the inlet of the liquid reservoir 5; the outlet of the liquid reservoir 5 is connected with the inlet of the drier filter 6, and the outlet of the drier filter 6 passes through the first ex...

Embodiment 2

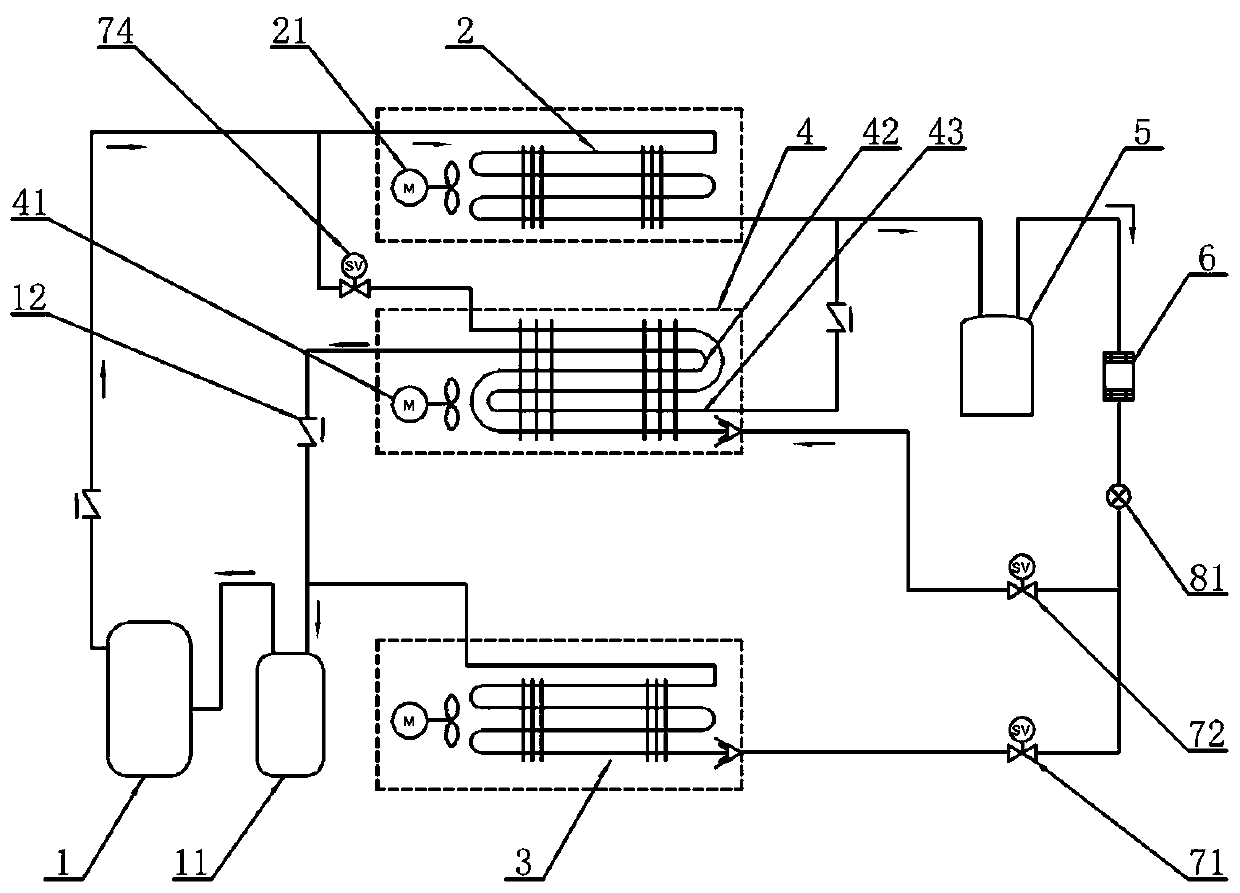

[0057] Embodiment 2: A kind of composite open and close cycle heat pump drying system, such as image 3 , 4 As shown, it includes a drying room 100, a heat pump drying subsystem, a drying air circulation subsystem and a control subsystem.

[0058] The heat pump drying subsystem includes a compressor 1, a main condenser 2, an indoor evaporator 3, an outdoor heat exchanger 4, a liquid receiver 5, a dry filter 6 and a gas-liquid separator 11; the outdoor heat exchanger 4 includes an outdoor fan 41 , the outdoor evaporator 42 and the outdoor condenser 43; the exhaust port of the compressor 1 is connected with the inlet of the main condenser 2 and the inlet of the outdoor condenser 43 respectively, and the outlet of the main condenser 2 and the outlet of the outdoor condenser 43 are respectively It is connected with the inlet of the liquid reservoir 5; the outlet of the liquid reservoir 5 is connected with the inlet of the dry filter 6, and the outlet of the dry filter 6 is connec...

Embodiment 3

[0073] Embodiment 3: A kind of composite open and close cycle heat pump drying system, such as Figure 5 , 6 As shown, it includes a drying room 100, a heat pump drying subsystem, a drying air circulation subsystem and a control subsystem.

[0074] In the heat pump drying subsystem, a three-way valve 10 is used to replace the first solenoid valve 71 and the second solenoid valve 72 in Embodiment 2, and the outlet of the first expansion valve 81 is connected to the inlet of the three-way valve 10; the three-way valve 10 The first outlet a of the three-way valve 10 communicates with the inlet of the indoor evaporator 3 ; the second outlet b of the three-way valve 10 communicates with the inlet of the outdoor evaporator 42 . The structure of other parts in the heat pump drying subsystem is the same as that in Embodiment 2.

[0075] The drying air circulation subsystem and the control subsystem are the same as those in Embodiment 1.

[0076] The working process of the multiple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com