Dual-temperature-heat-pipe constant-temperature and constant-humidity air-conditioning unit

A technology of constant temperature and humidity, air-conditioning units, applied in air-conditioning systems, household heating, heating methods, etc., can solve the problems of not being able to meet the temperature and humidity control requirements at the same time, affecting control accuracy, and high investment at one time, so as to solve the cold and heat offset problems, reduced reheat energy consumption, and the effect of high energy efficiency of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

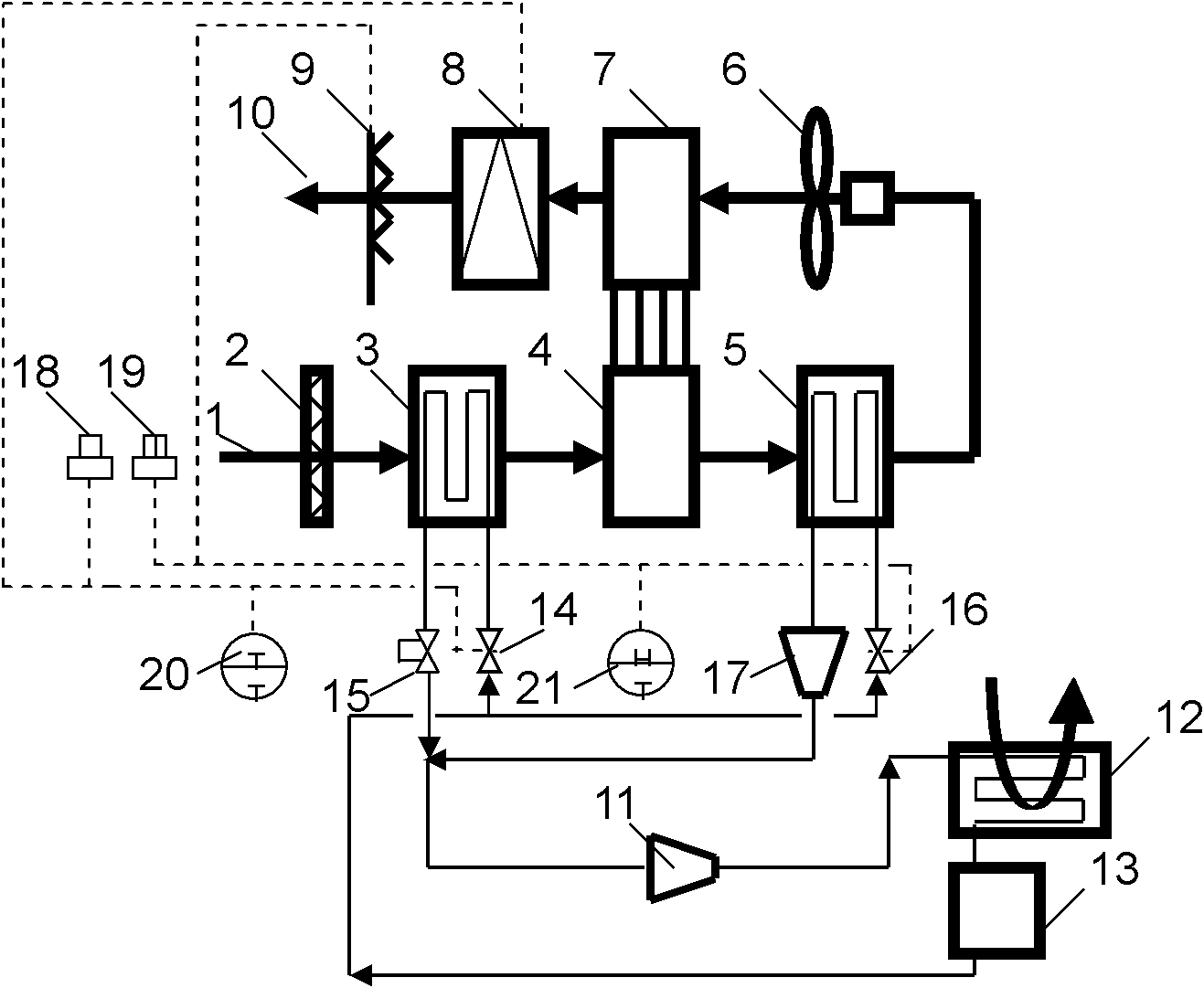

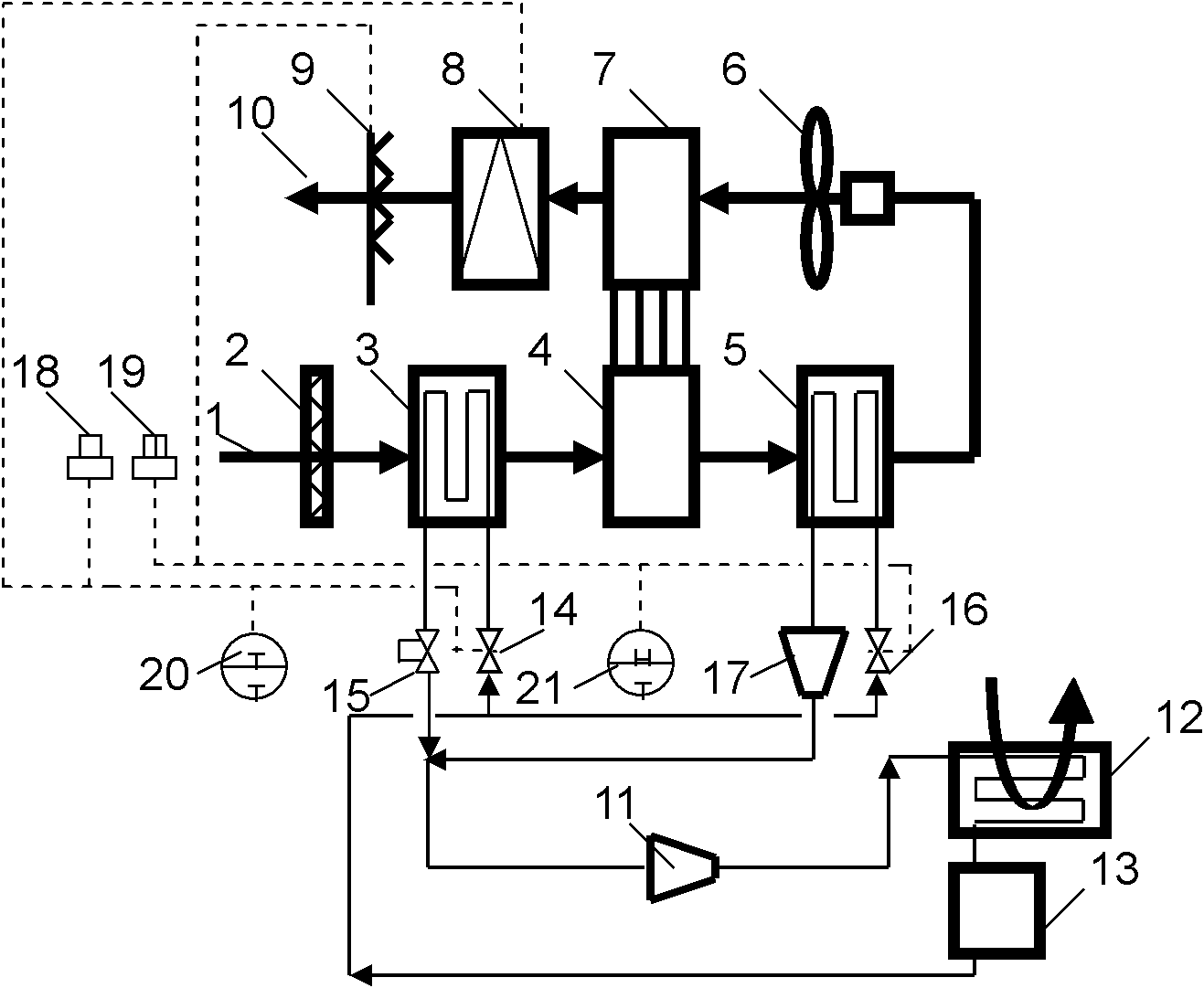

[0037] Embodiment 1, figure 1 A dual-temperature heat pipe constant temperature and humidity air conditioning unit is given, including an air treatment cycle system coupled with a high-temperature evaporator 3 and a low-temperature evaporator 5 and a two-stage compression dual-temperature refrigeration cycle system.

[0038] The air treatment cycle system includes air inlet 1, filter 2, high temperature evaporator 3, heat pipe heat exchanger evaporation section 4, low temperature evaporator 5, blower fan 6, heat pipe heat exchanger condensation section 7, electric Heater 8, electrode type steam humidifier 9 and air supply port 10; the heat pipe heat exchanger is composed of the interconnected heat pipe heat exchanger evaporation section 4 and heat pipe heat exchanger condensation section 7; the heat pipe heat exchanger is an integral gravity heat pipe Heat exchanger, the evaporating section 4 of the heat pipe heat exchanger is located below the condensing section 7 of the heat...

Embodiment 2

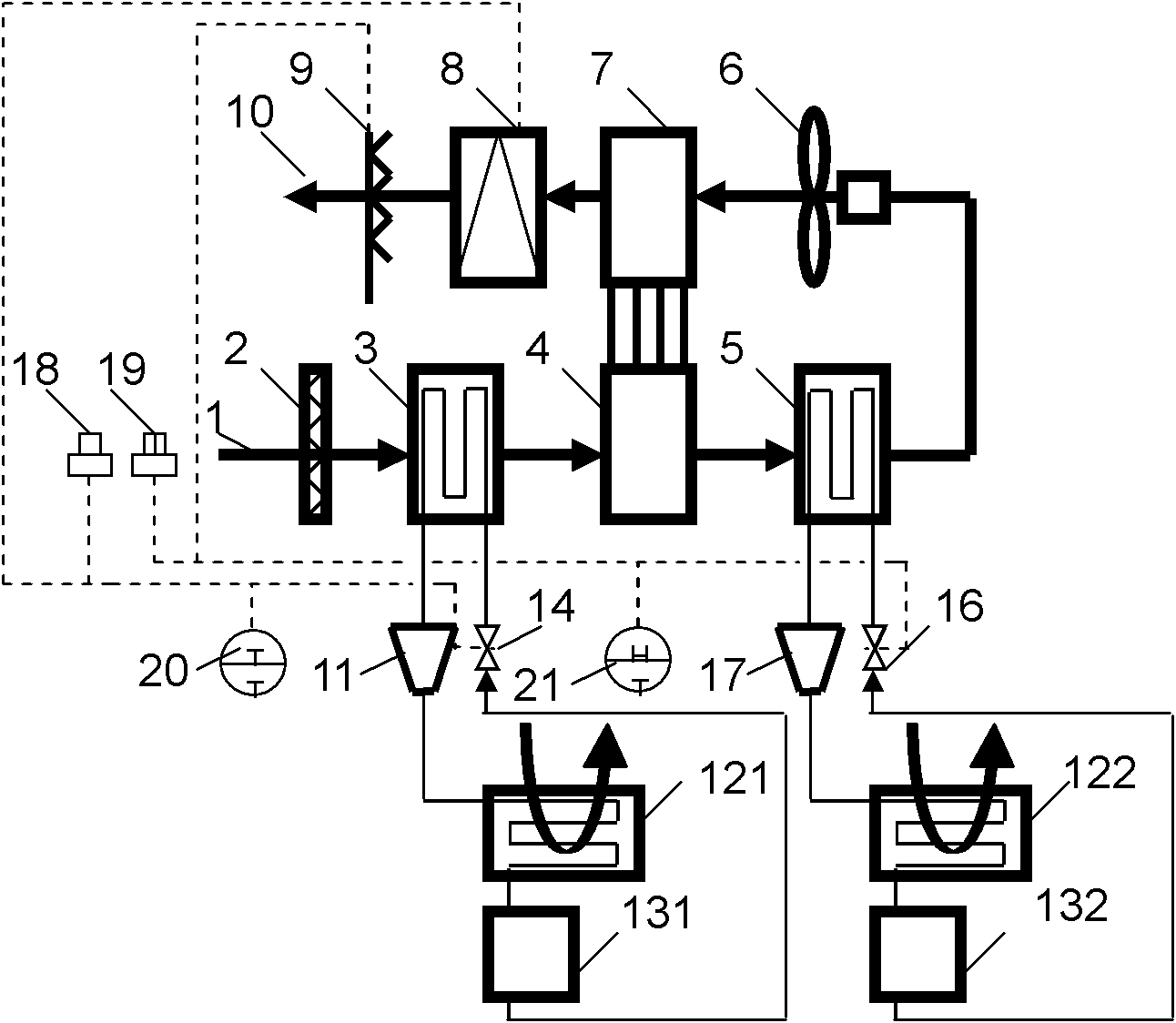

[0058] Embodiment 2, figure 2 A dual-temperature heat pipe constant temperature and humidity air conditioning unit is given, including an air treatment circulation system coupled with a high-temperature evaporator 3 and a low-temperature evaporator 5 and a dual-loop refrigeration circulation system.

[0059] The dual-circuit refrigeration cycle system consists of a high-pressure stage refrigeration cycle and a low-pressure stage refrigeration cycle that are independent of each other.

[0060] The high-pressure stage refrigeration cycle loop is composed of the outlet of the high-pressure stage compressor 11, the high-pressure stage condenser 121, the high-pressure stage liquid receiver 131, the high-pressure stage throttle valve 14, the high-temperature evaporator 3 and the high-pressure stage compressor 11 which are connected in sequence. The inlet is composed of; the high-pressure stage accumulator 131 is located below the high-pressure stage condenser 121 .

[0061] The lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com