Heating station for implementing trans-season heat storage, cooling-storage adopting combined pump technology

A combined pump and cross-seasonal technology, which is applied in the field of thermal stations for central heating, can solve the problems of commercial application of heat storage and heat supply across seasons.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

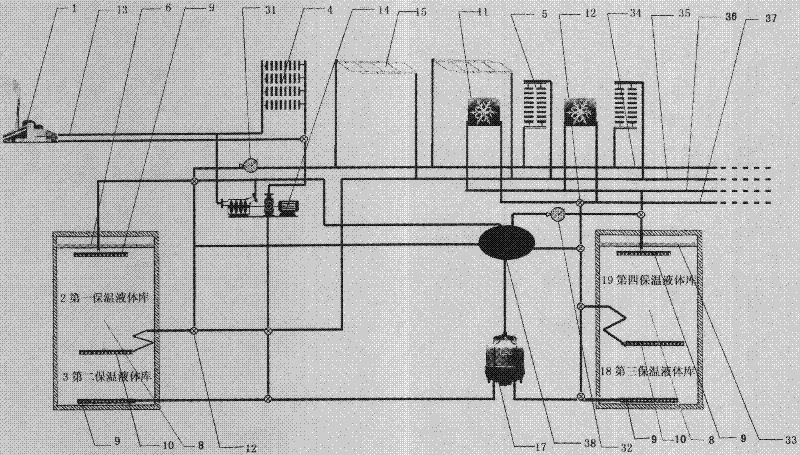

Embodiment 1

[0036] The combined pump 14 decompresses the hot liquid 8 of the main heat network 13 and introduces it into the inner pipe network, and pumps the equivalent liquid 8 of the inner pipe network to the main heat network 13 . Build a heat storage and heat preservation liquid storehouse with a volume of 1 million cubic meters near the combined pump 14 or the main heat network heat exchanger 39, the part whose upper layer temperature is higher than 60°C is the first heat preservation liquid storehouse 2, and the lower layer temperature is lower than 60°C The part is the second heat preservation liquid storehouse 3; the cold storage heat preservation liquid storehouse with a volume of 1,000,000 cubic meters is set, the part whose upper layer temperature is higher than 15°C is the fourth heat preservation liquid storehouse 19, and the part whose lower layer temperature is lower than 15°C is The third heat preservation liquid storehouse 18 . The excess hot liquid 8 in the internal pip...

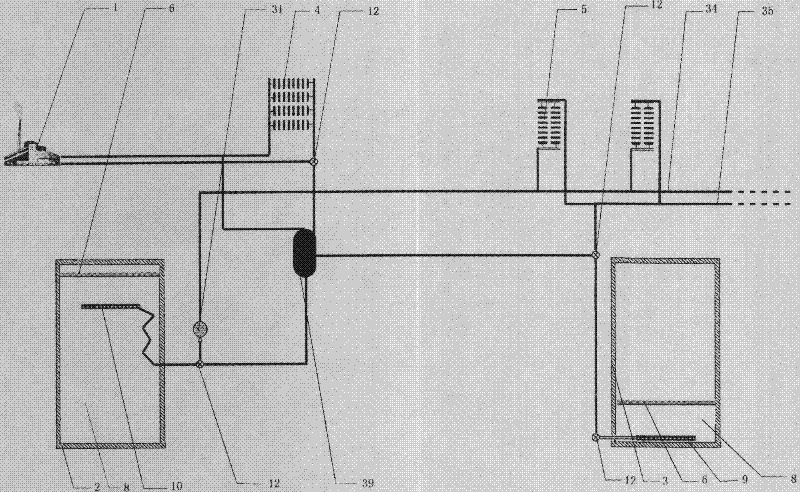

Embodiment 2

[0040] The main heat network heat exchanger 39 is used to transfer the heat energy of the main heat network 13 to the inner pipe network. The first heat preservation liquid storehouse 2 and the second heat preservation liquid storehouse 3 with a volume of 500,000 cubic meters are respectively constructed in sub-pools near the main heat network heat exchanger 39, and the surplus heat liquid 8 of the inner pipe network is injected into the first heat preservation liquid storehouse 2, At the same time, the hot liquid return pipe 35 extracts an equivalent amount of liquid 8 from the second heat preservation liquid storehouse 3 . External heat source 1 is the waste heat of cooling water and waste heat of flue gas recovered by a steel plant. Heat users 5 include heating radiators and centralized hot water supply devices. When the heat supply of the hot liquid 8 in the internal pipe network is insufficient, the hot liquid 8 in the first thermal insulation liquid storage 2 is extract...

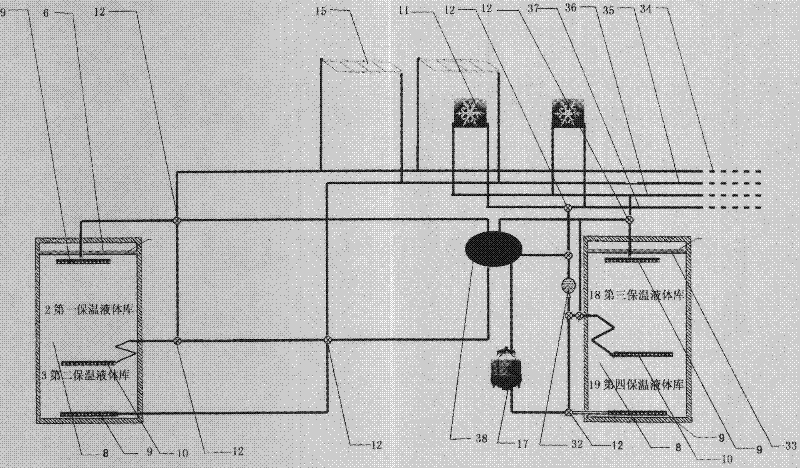

Embodiment 3

[0043]Build a heat storage and thermal insulation liquid storage with a volume of 300,000 cubic meters, the part whose upper layer temperature is higher than 60°C is the first thermal insulation liquid storage 2, and the part whose lower layer temperature is lower than 60°C is the second thermal insulation liquid storage 3; construction A cold-storage heat preservation liquid storehouse with a volume of 300,000 cubic meters, the part whose upper temperature is higher than 15°C is the fourth heat preservation liquid storehouse 19, and the part whose lower floor temperature is lower than 15°C is the third heat preservation liquid storehouse 18. Three liquid distributors 9 are respectively arranged in the two pools, one at the top and one at the bottom, and a liquid distributor 10 that can move up and down in the middle. The internal heat source 15 feeds the hot liquid 8 into the hot liquid pipe 34 and draws an equal amount of liquid 8 from the hot liquid return pipe 35 at the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com