Boiling regeneration type heat pump system for heat source tower

A heat source tower heat pump and heat source tower technology, applied in energy-saving heating/cooling, lighting and heating equipment, and compressors with reversible cycles, etc., can solve the problems of heating and regenerating air with too much heat, reducing heat pump systems, and high energy consumption. Achieve high regeneration efficiency, strong mass transfer effect, and reduce regeneration load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

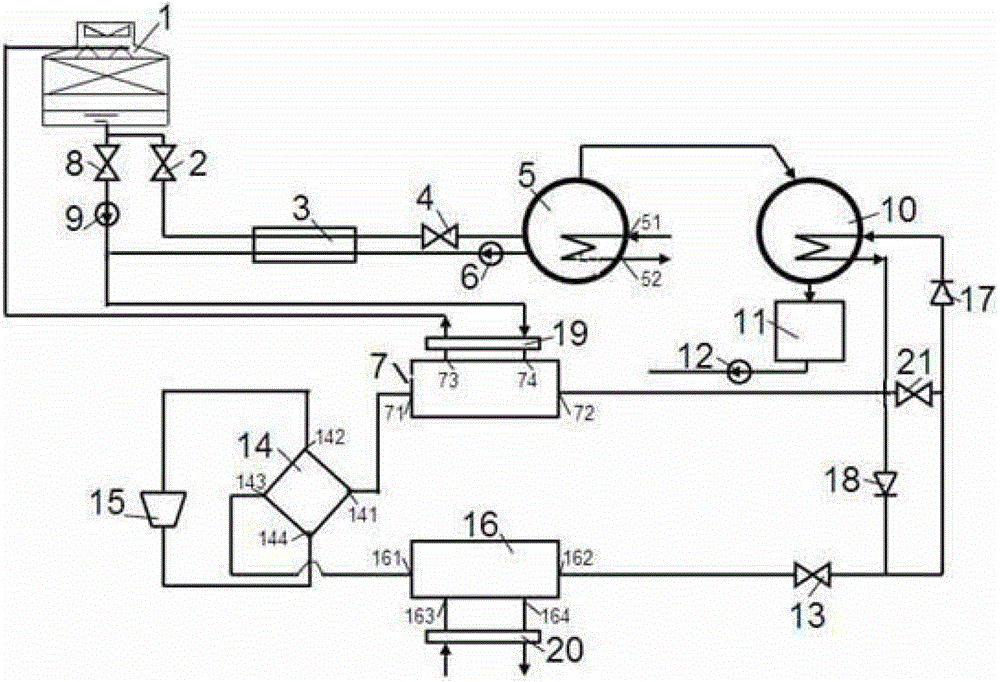

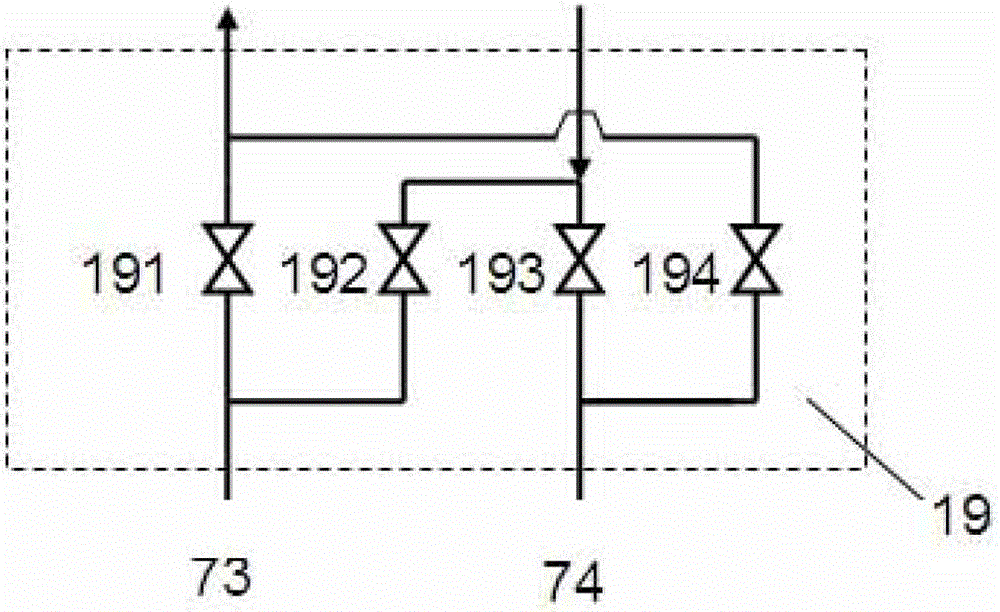

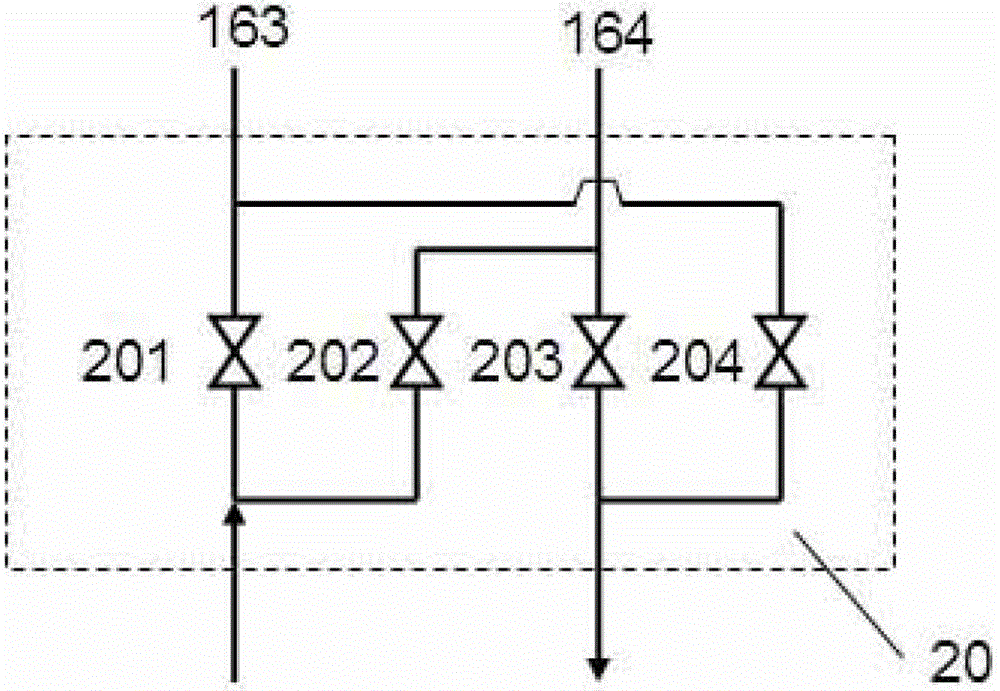

[0016] Implementation example 1, figure 1 A boiling regenerative heat source tower heat pump system is given; it includes heat pump subsystem, heat source tower subsystem and solution regeneration subsystem; solution regeneration subsystem includes regulating valve Ⅰ2, solution heat exchanger 3, throttle valve Ⅰ4, boiling regeneration 5, solution increasing pump 6, condenser 10, condensed water tank 11 and condensed water pump 12; heat pump subsystem includes outdoor heat exchanger 7, four-way reversing valve 14, compressor 15, indoor heat exchanger 16, throttle valve II13, condenser 10, one-way valve I18, one-way valve II17 and bypass valve 21; heat source tower subsystem includes heat source tower 1, regulating valve II8, circulation pump 9, outdoor heat exchanger 7 and outdoor conversion valve group 19. The three subsystems mentioned above are coupled, that is, the heat pump subsystem is coupled with the heat source tower subsystem through the outdoor heat exchanger 7 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com