A method for recovering ethane from high-pressure natural gas

A recovery method, natural gas technology, applied in chemical instruments and methods, climate sustainability, absorption purification/separation, etc., can solve the difficulty of reboiler and raw gas heat integration, increase energy consumption and investment of public works, reboil Improve the temperature and heat load of the device to achieve the effect of high pressure, enhanced adaptability and reduced compression work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0032] Composition and working conditions of raw material gas after dehydration:

[0033] Raw gas processing scale: 1000×10 4 m 3 / d

[0034] Raw gas pressure: 7.0MPa

[0035] Feed gas temperature: 33°C

[0036] Natural gas export pressure: ≥6.0MPa

[0037] The raw gas composition is shown in Table 1.

[0038] Table 1. Composition of feed gas after dehydration

[0039] natural gas components N 2

CO 2

C 1

C 2

C 3

iC 4

c 4

Natural gas composition, mol% 0.61 3.00 89.09 4.70 1.40 0.27 0.30 natural gas components iC 5

c 5

C 6

C 7

C 8

C 9

C 10

Natural gas composition, mol% 0.13 0.09 0.13 0.10 0.09 0.06 0.04

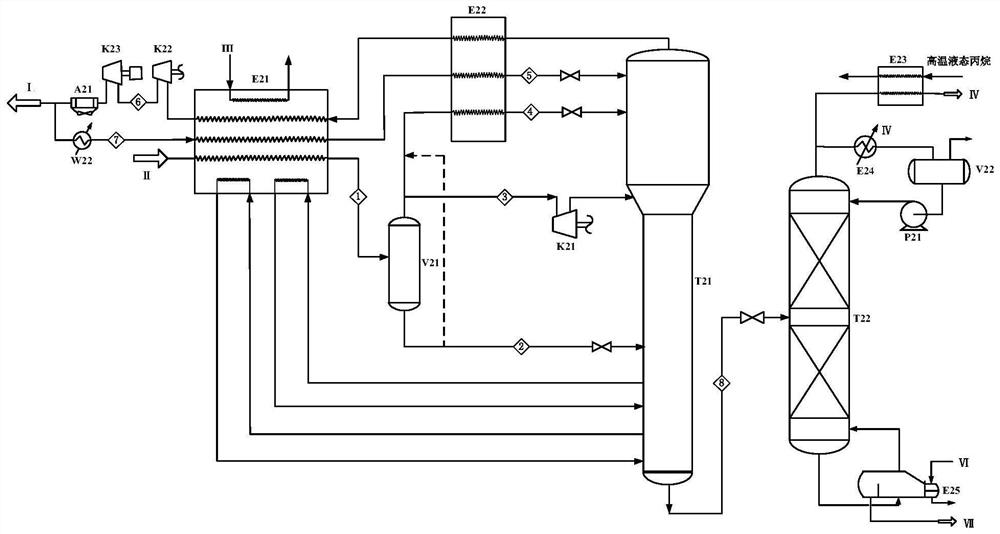

[0040] The process flow sheet of natural gas ethane recovery method embodiment 1 provided by the invention is as image 3 As shown, the process is briefly described as follows:

[0041] (1) After dehydration, the raw material gas (7.0MPa, 34°C) is cooled to -43°C...

example 2

[0051] Composition and working conditions of raw material gas after dehydration:

[0052] Raw gas processing scale: 1000×10 4 m 3 / d

[0053] Raw gas pressure: 8.0MPa

[0054] Feed gas temperature: 37°C

[0055] Natural gas export pressure: ≥6.0MPa

[0056] The raw gas composition is shown in Table 3.

[0057] Table 3. Raw material gas composition after dehydration

[0058] natural gas components N 2

CO 2

C 1

C 2

C 3

iC 4

c 4

Natural gas composition, mol% 1.02 0.1 88.54 7.41 1.50 0.3 0.31 natural gas components iC 5

c 5

C 6

C 7

C 8

C 9

C 10

Natural gas composition, mol% 0.13 0.09 0.15 0.20 0.18 0.05 0.02

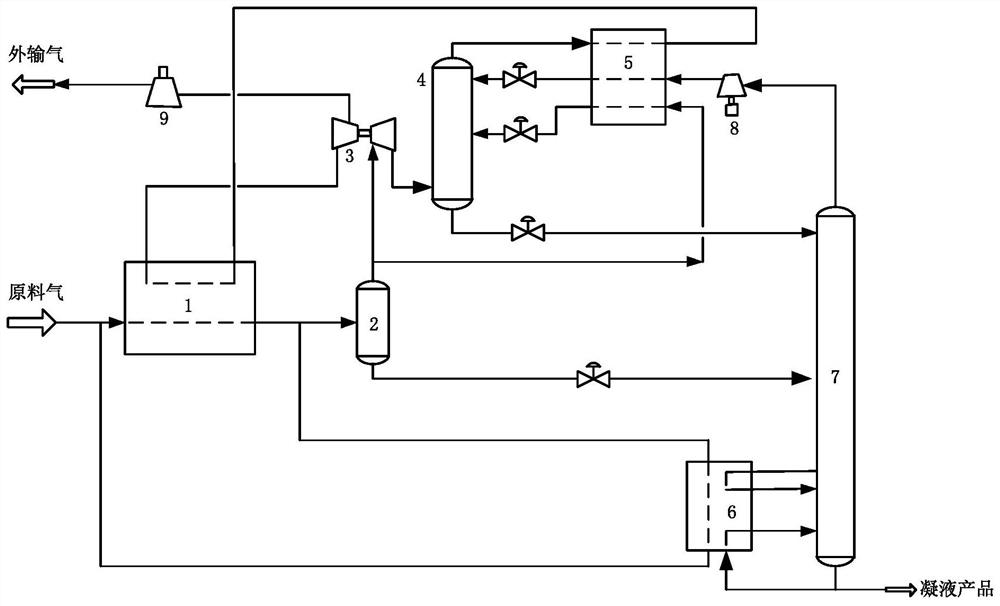

[0059] The process flow diagram of the natural gas ethane recovery method embodiment 2 provided by the invention is as Figure 4 As shown, the process is briefly described as follows:

[0060] (1) After dehydration, the raw material gas (8.0MPa, 37°C) is coole...

example 3

[0069] Composition and working conditions of raw material gas after dehydration:

[0070] Raw material gas treatment scale: 1000×104m3 / d

[0071] Raw gas pressure: 6.0MPa

[0072] Feed gas temperature: 37°C

[0073] Natural gas export pressure: ≥6.0MPa

[0074] The raw gas composition is shown in Table 5.

[0075] Feed gas composition after table 5 dehydration

[0076] natural gas components N 2

CO 2

C 1

C 2

C 3

c 4

Natural gas composition, mol% 0.61 2 90.09 4.7 1.40 0.4 natural gas components iC 5

c 5

C 6

C 7

C 8

C 10

Natural gas composition, mol% 0.13 0.09 0.13 0.10 0.09 0.04

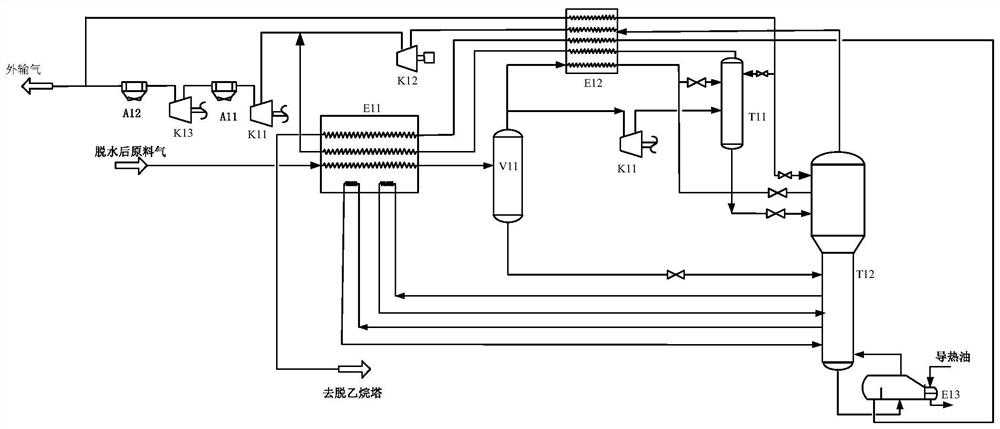

[0077] The process flow diagram of the natural gas ethane recovery method embodiment 3 provided by the invention is as Figure 5 As shown, the process is briefly described as follows:

[0078] After dehydration, the raw material gas (6.0MPa, 37°C) is cooled to -43°C by the main cold box (E11) and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com