Drying device with combination of heat pump and rotating wheel

A drying device and runner technology, which is used in dryers for static materials, local stirring dryers, drying, etc., can solve the problem of large increase in energy consumption, increase in system energy consumption, and limit the application range of rotary dehumidifiers. and other problems, to achieve the effect of reducing the energy consumption of reheating, reducing the energy consumption of the drying system, and overcoming the deep drying of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Adopt the device of the present invention to dry 5kg of fresh jujubes, after cleaning, draining and finishing, the initial moisture content is about 80%, the drying medium is air, the drying temperature is 50°C, the relative humidity is 11.8%, the heat pump working medium is R134a, and the evaporation pressure is 0.66 MPa, condensing pressure 1.69MPa. The lithium chloride dehumidification wheel is used, and the regeneration temperature is 70°C. Stop drying when the water content of jujube drops to about 20%. Compared with heat pump drying, the drying time is shortened by about 10%, and the energy consumption is saved by 40%.

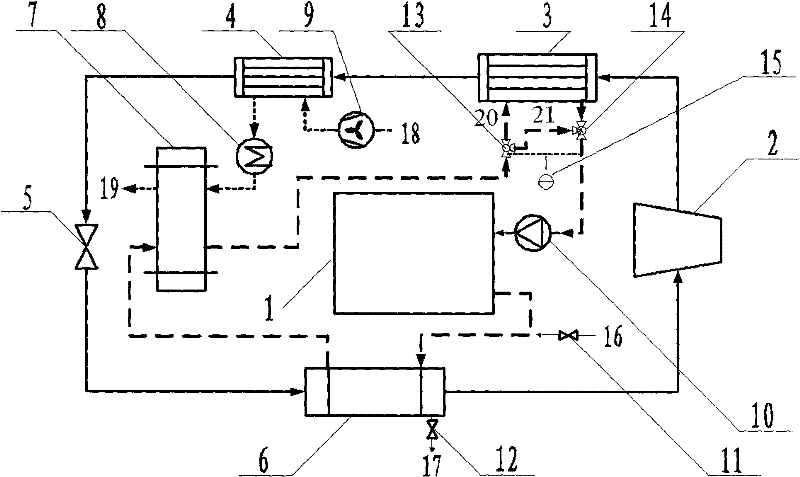

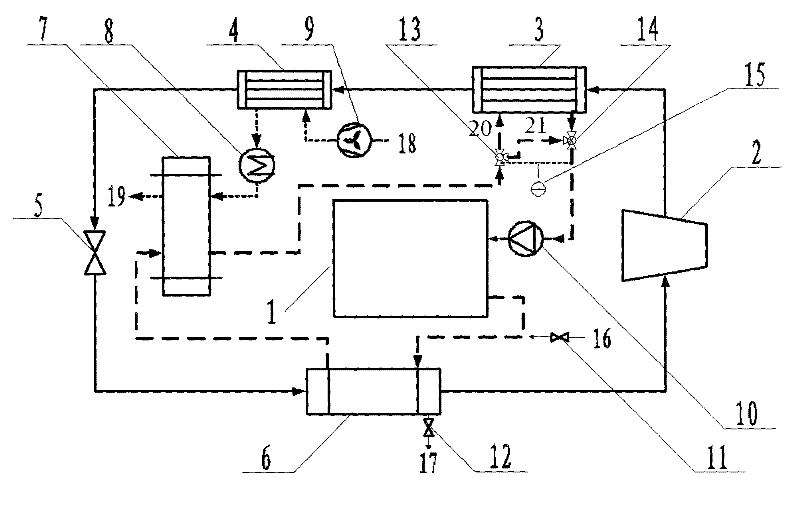

[0032] The drying device of the present invention includes a drying system, a heat pump and a runner regeneration device. The drying system includes a material drying chamber 1, an evaporator 6, a dehumidification wheel 7, a main condenser 3 and a circulation fan 10 connected in sequence, and the circulation fan 10 is connected with the material...

Embodiment 2

[0048] Adopt the device of the present invention to dry pig leather. Pig leather is squeezed, shaved, and washed for 20 minutes. After the treatment, the sample is placed for 2 days. After squeezing, it is divided into 5 pieces of the same size, each piece has a thickness of 0.9mm and a mass of 0.8kg. , the water content is about 60%. The drying medium is air, the drying temperature is 35°C, the relative humidity is 5%, the heat pump working fluid is R290 / R600a, and the parameters are set as follows: condensing pressure and evaporating pressure are 0.65, 0.16MPa, condensing temperature and evaporating temperature are 0, 45°C . The lithium chloride dehumidification rotor is adopted, and the regeneration temperature of the rotor is 80°C. Stop drying when the content of leather drops to 20%. Compared with heat pump drying, the drying time is shortened by about 15%, and the energy consumption is saved by about 40-50%.

Embodiment 3

[0050] Adopt device of the present invention to dry Masson pine, Masson pine thick 20mm, volume 0.1m 3 , the moisture content is about 40%, the drying medium is air, the relative humidity is 15%, and the temperature is 70°C for one hour, then switch to 40°C for 10 minutes, then switch to 70°C, and so on. The working fluid of the heat pump is R32 / R152a, and the parameters are set as follows: the condensing pressure and evaporating pressure are 2.37 and 0.45MPa respectively, and the condensing temperature and evaporating temperature are 80 and 15°C respectively. The lithium chloride dehumidification rotor is used, and the regeneration temperature of the rotor is 70°C. Stop drying when the moisture content of masson pine drops to about 10%. Compared with heat pump drying, the drying time is shortened by about 8-10%, and the energy consumption is saved by about 25-40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com