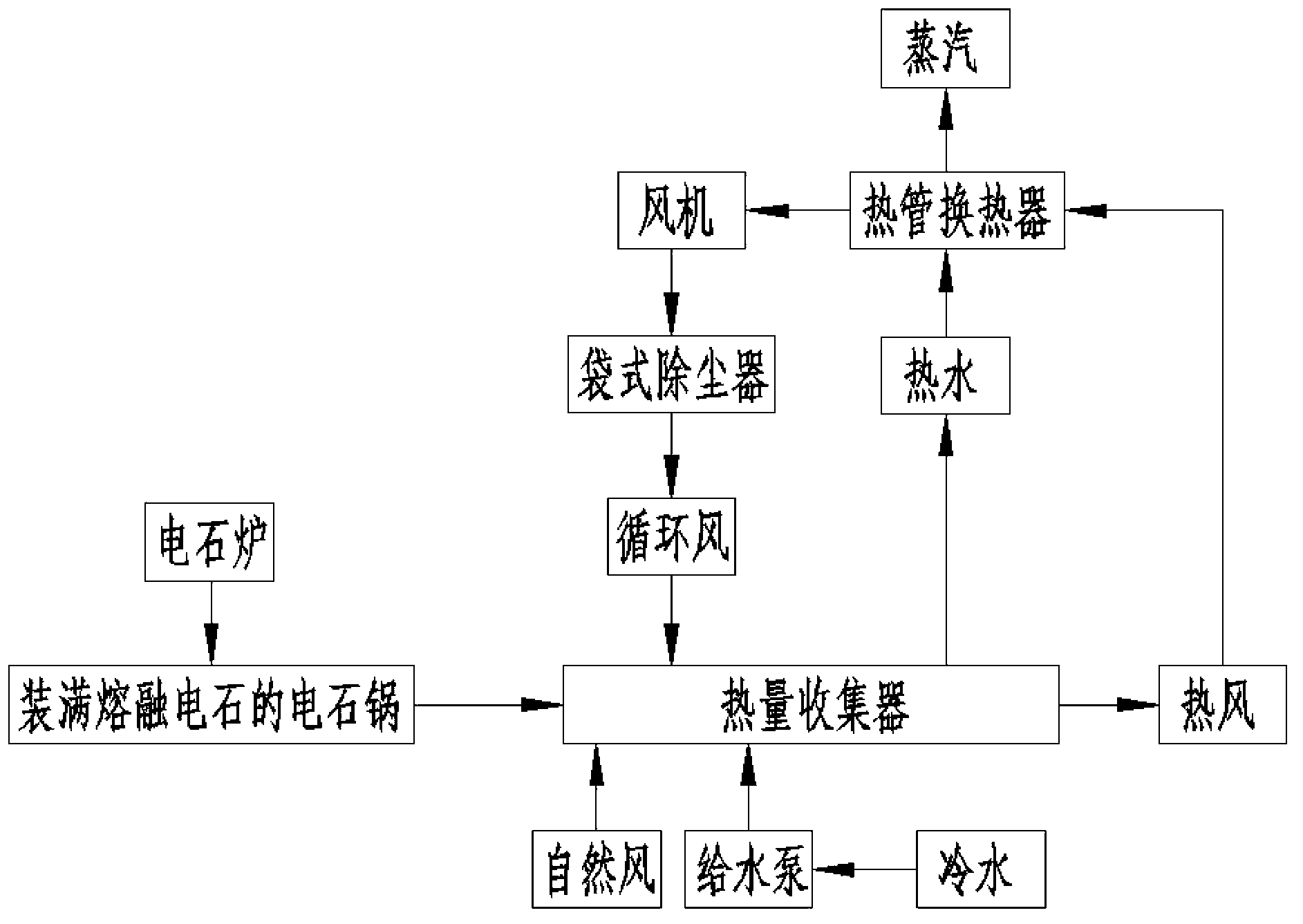

Waste heat recovery device and waste heat recovery method during condensation of molten calcium carbide

A waste heat recovery device and condensation process technology, applied in the field of waste heat recovery, can solve the problems of low air enthalpy and high power consumption, and achieve the effects of improving the working environment, saving energy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

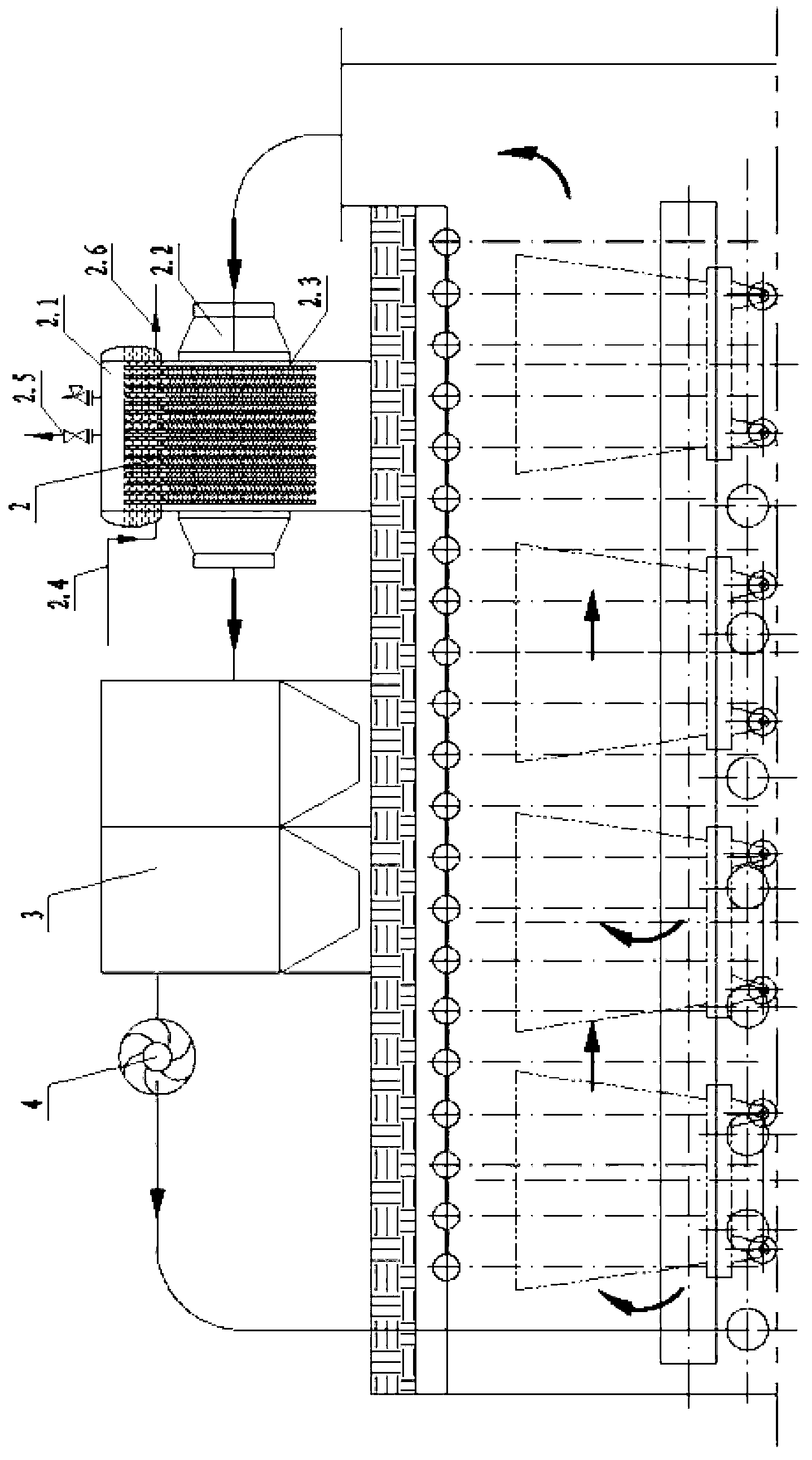

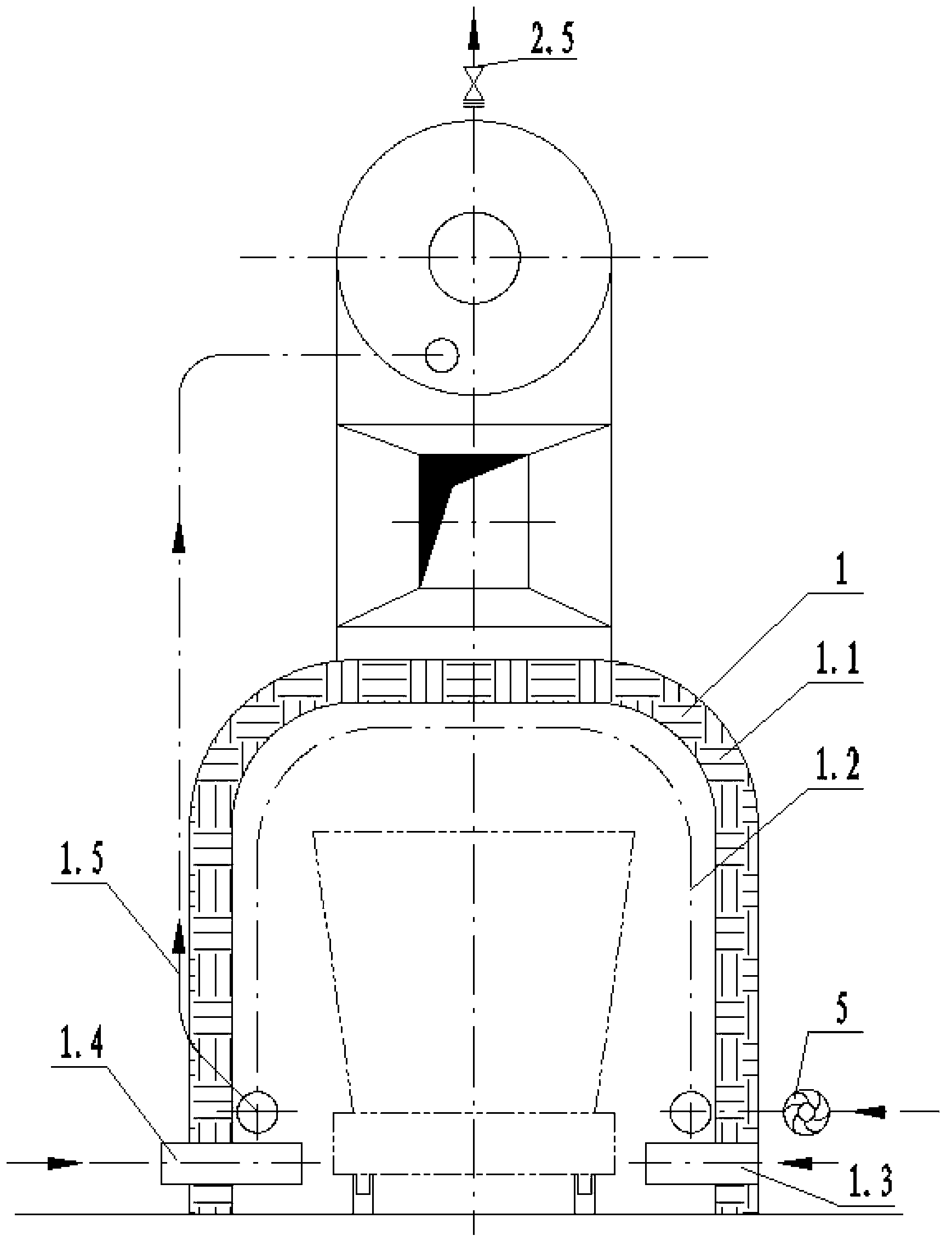

[0032] The present invention will be further described below in conjunction with drawings and embodiments.

[0033] Embodiment is shown in accompanying drawing. The waste heat recovery device in the condensation process of molten calcium carbide includes heat collector 1, heat pipe heat exchanger 2, dust remover 3, fan 4 and feed water pump 5, heat pipe heat exchanger 2, dust remover 3, fan 4 and feed water pump 5 are placed in Outside the heat collector 1, the heat collector 1 is placed on the track of the electric stone pot carrying trolley. The heat collector 1 is a closed box, and the two ends of the box are provided with sealed doors for the stone pot carrying trolley to enter and exit. There is heat-resistant insulation material 1.1, and membrane wall tube 1.2 is provided on the top of the box and the inner surface of the two side walls. The water inlet 2.4 of the steam drum 2.1 of the heater is connected, the lower part of the two side walls of the box body is respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com