Method and device for recycling waste heat of steam

A waste heat recovery device and water vapor technology, applied in cooking utensils, household appliances, applications, etc., can solve the problems of taking away heat energy and increasing the temperature of the kitchen working environment, and achieve the effects of reducing heat energy loss, simple structure, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment do further explanation.

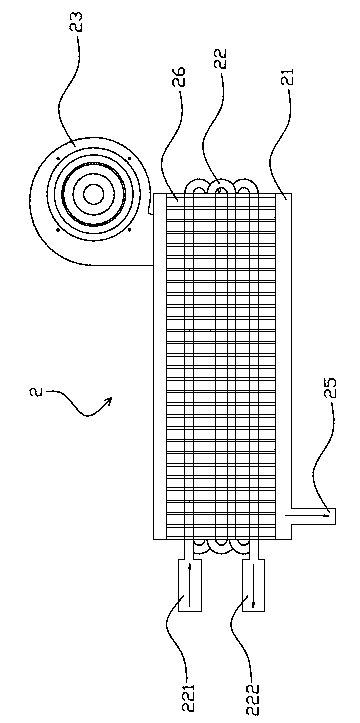

[0015] The water vapor waste heat recovery method of the present invention recovers part or all of the water vapor used in the circulating heating system to the thermal energy converter, and the air in the thermal energy converter is heated and then drawn out from the thermal energy converter.

[0016] Part or all of the heated air drawn from the heat energy converter is sent back to the circulating heating system.

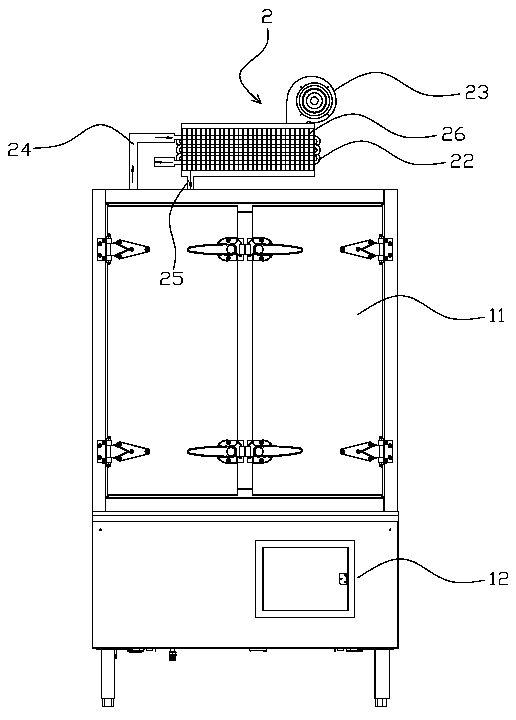

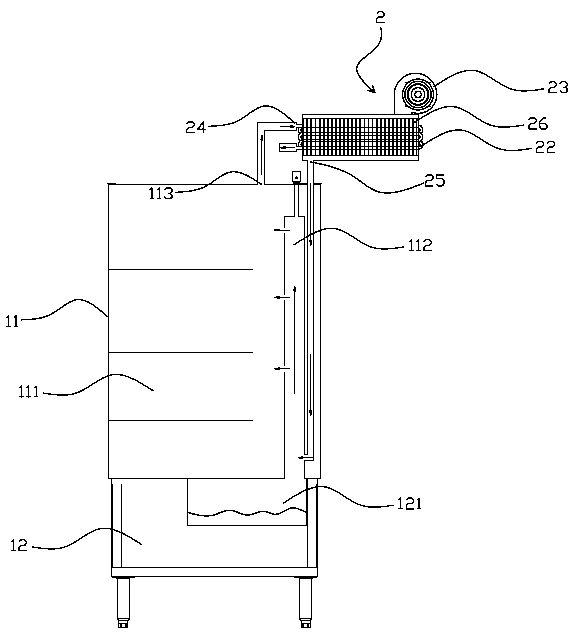

[0017] The structural representation of the steam waste heat recovery device of the present invention is as follows: figure 1 , figure 2 As shown, it includes an upper cabinet 11 and a lower cabinet 12. The upper cabinet 11 includes a number of independent steaming chambers 111. A steamer 121 is arranged in the lower cabinet 12. A heater is installed on the side of the steamer 121. , the steamer 121 communicates with the steam chamber 111 through the steam delivery pipe 112, the heat energy c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com